Stepper Motors for Automated Guided Vehicles (AGVs)

Automated Guided Vehicles (AGVs) are self-driven vehicles designed to transport materials from one area to another, especially in warehouses, manufacturing plants, and distribution centres. At the heart of the AGVs, there is a motion control system that consists of stepper motors and gearboxes for precision and controllability.

Automated Guided Vehicles are an ideal application of modern logistics, material handling in warehouses and distribution centres. They transport material with speed, accuracy and efficiency. Their motion depends on precise navigation and reliable operation under varying loads.

At the heart of the AGVs, there is a motion control system that consists of motors and gearboxes, which play a pivotal role in the operation. Among the various motors, stepper motors have emerged as the ideal solution due to their precision and controllability.

In this blog, we will explore the role of the stepper motor in AGV, focusing on how its accuracy and efficiency help AGV to enhance its operation.

What are AGVs and Their Motion Requirements

Automated Guided Vehicles (AGVs) are self-driven, algorithm-controlled vehicles designed to transport materials from one area to another, especially in warehouses, manufacturing plants, and distribution centres.

The AGVs operate without humans and follow a predefined path guided by technologies such as magnetic strips, laser navigation, and LiDAR. They are the crucial component in intralogistics which enable efficient and reliable material handling while reducing labour dependency.

However, the motion requirements for the AGVs are crucial for their performance. Since they operate in a very tight space, precision motion is necessary. They also require maintaining positioning and proper path tracking to avoid collision.

Watch the YouTube Video by "TRADESAFE" about AGVs in warehousing and manufacturing

AGVs require control acceleration and deceleration to handle loads with stability and precision. Speed control is also required for different tasks and different velocities. Slow speed and high accuracy for proper placement of material, while fast speed to travel long distances.

Therefore, AGVs require a precise, stable, and adaptive motion control system to achieve and seamless operation in an industrial environment.

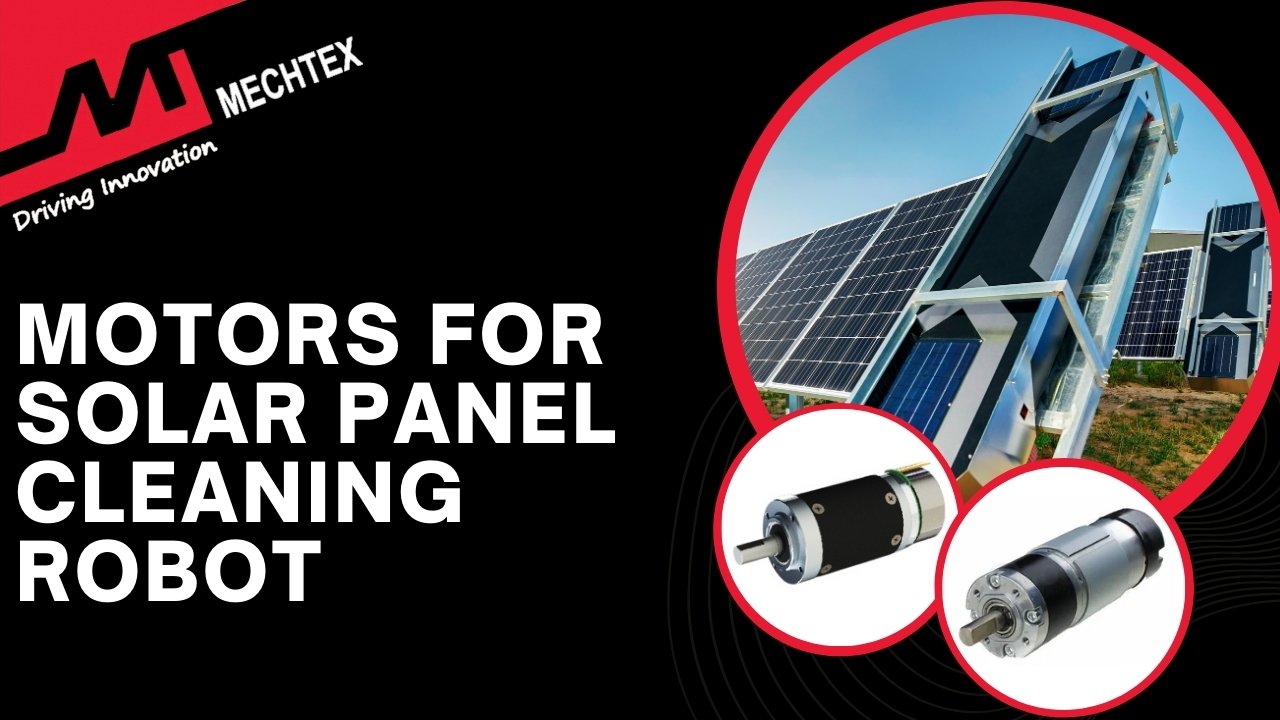

Why Stepper Motors Are Ideal for AGVs

Stepper motors are electromagnetic devices which convert electrical pulses into precise mechanical movements. Unlike other motors that rotate continuously, stepper motors move in discrete steps, allowing accurate positioning, accuracy and repeatability.

These characteristics make the stepper motor an inherent component of AGV without any feedback system. The following are some reasons why stepper motors are ideal for AGVs:

- High Positional Accuracy

As stepper motors move in discrete steps, this enables precise control for distance and angles. This ensures that AGVs stop at the exact point of placement.

- Simplified Control

With step-based operation, the stepper motor responds directly to input pulses from the controller, which eliminates the need for an encoder and makes it a compact application.

- Cost-Effectiveness

Stepper motors are more economical compared to servomotors and deliver the accuracy and precision required for AGVs.

- Torque at Low Speeds

Stepper Motors deliver high torque at low speed, which is ideal to control AGVs acceleration and deceleration easily.

Role of Gearboxes in Stepper Motors for AGVs

While stepper motors provide accuracy, sometimes they require additional torque to handle heavy loads easily. This is where gearboxes come into play. Below are some benefits of adding gearboxes to stepper motors in AGVs

- Torque Amplification

Gear reduction multiplies the torque output, which enables AGVs to carry heavy payloads easily.

- Speed Control

As multiple gear ratios reduce the motor output speed, which AGVs require this for smoother motion in compact areas.

Enhanced Efficiency:

Gearboxes help the motor to produce sufficient torque, which helps AGVs in handling heavy loads with proper energy consumption.

Therefore, stepper motors with gearboxes ensure the combination of precision, accuracy and high torque for smooth operation of AGV.

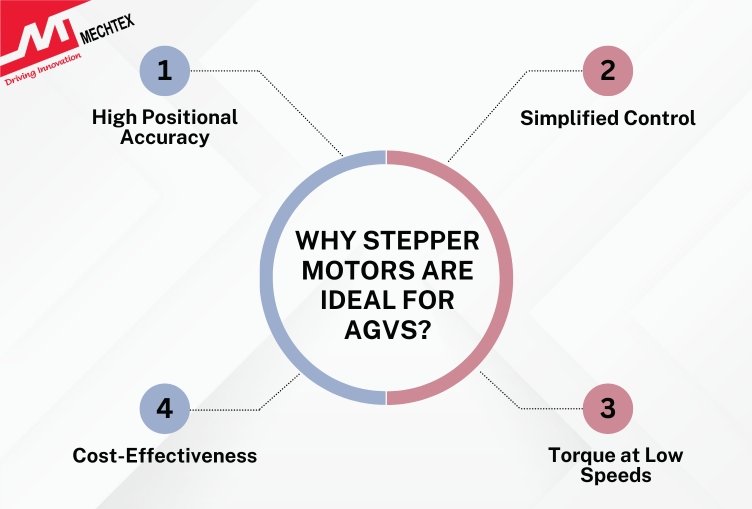

Applications of Stepper Motors in AGVs

Stepper motors with gearboxes are deployed in various AGV subsystems:

- Drive System

In AGVs, stepper motors with gearboxes power the drive system by enabling precise forward and backwards motion. The gear reduction from the gearbox enables smooth accelerations and reduces jerks for efficient material handling.

- Steering Mechanism

This mechanism depends upon stepper motors for precise directional control. Stepper motor step-by-step motion enables accurate angle positioning and allows AGVs to navigate narrow paths with accuracy.

- Lifting and Loading Systems

AGV pallet handling system, powered by stepper motors for lifting and loading payloads vertically.

When stepper motors are paired with gearboxes, they deliver the high torque required for the pallet handling system to raise and position the payload safely.

Stepper Motors vs Other Motor Types in AGVs

Seervo motors and BLDC motors are also used in AGVs, but stepper motors have some advantages compared to these motors. Here brief comparison of the stepper motor with the servo motor, and the BLDC motor below:

- ServoMotor vs Stepper Motor

Servomotors excel in high-speed dynamic applications by offering rapid response with continuous feedback.

In contrast, stepper motors are simple in design and provide sufficient torque and reliable performance for precise operation.

For many tasks of AGVs, like navigation and lifting, stepper motors are ideal for reliable performance.

- BLDC Motor vs Stepper Motor

BLDC motors are highly efficient for high-speed applications, but they depend upon the controller to achieve precise positioning.

While stepper motors inherently excel in incremental movements, which makes them more suitable for navigation and handling tasks common in AGVs.

Conclusion

AGVs are transforming material handling by bringing precision, efficiency, and automation to industrial operations. Stepper motors with gearboxes form the backbone of their motion systems, offering unmatched positional accuracy, torque adaptability, and reliability at cost-effective levels.

By delivering smooth, controlled motion under varying loads, these motors ensure AGVs perform consistently in dynamic environments. As industries continue to adopt AGVs for smart logistics, stepper motors will remain a cornerstone of precise and dependable automation.