What is a BLDC Motor? Introduction, Construction & Applications

Explore what a BLDC motor is, how brushless DC motors work with electronic commutation, their construction, advantages over brushed motors, and common applications.

What is a BLDC Motor?

A BLDC Motor is also commonly known as a brushless DC motor. It is a highly efficient and powerful motor that has gained popularity in various industries due to its high efficiency and precise control. It is powered by a direct current (DC) voltage supply and does not have brushes or a commutator.

Check out the video below by "Mechtex" to learn about BLDC Motors

The difference between brushless DC motors and conventional DC motors is, that in conventional DC motors, brushes are used to transfer the power to the rotor as they turn in a fixed magnetic field, while brushless DC motors are commutated electronically, thereby eliminating the use of brushes.

BLDC motors are broadly used in various applications owing to their smooth and highly efficient operation. It also has power-saving advantages as compared to other types of motors.

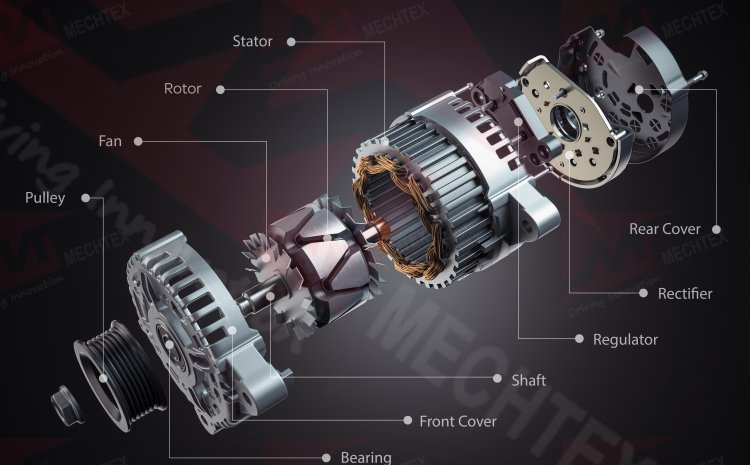

Construction of BLDC Motors

In a BLDC motor, the mechanical commutator used in the conventional DC motor is replaced with an electric switch circuit. A brushless DC Motor is a type of synchronous motor. Therefore, the magnetic field generated by the stator and the rotor revolves at the same frequency.

A BLDC motor consists of the following parts:

-

Stator

The stator of a BLDC motor is similar to the one used in an induction motor. The stator is built of steel laminations that are stacked together with slots for winding, which are axially cut. Most BLDC motors consist of three stator windings that are connected in a star or ‘Y’ arrangement.

-

Rotor

The rotor of a BLDC motor consists of permanent magnets (Samarium Cobalt (SmCo), Neodymium (Nd), alloy of Neodymium, Ferrite and Boron (NdFeB)). The arrangement of poles can vary according to the number of poles, depending on the application of the motor.

- Position Sensors (Hall Sensors)

Since BLDC motors are commutated electronically, the windings of the stator must be energised in a sequence, and the position of the rotor must be known to precisely energise a particular set of stator windings to rotate the motor.

A Position Sensor or a Hall Sensor is a sensor that works on the principle of the Hall Effect. Its function is to detect the position of the rotor and transform it into an electrical signal. These sensors are embedded into the stator to detect the rotor’s position. Usually, three Hall sensors are required in a BLDC motor.

Also Read

Advantages of BLDC Motors

BLDC motors can be controlled using feedback mechanisms to give the required torque and rotation speed. Precision control, in turn, lessens energy utilisation and heat generation. In certain cases, where motors are powered by a battery, the precision control enhances the battery life.

BLDC motors also offer high durability and low electric noise generation owing to the lack of brushes. With brushed motors, the brushes and commutator wear down because of the continuous moving contact and also produce sparks at the point of contact.

Particularly, electrical noise is a consequence of the strong sparks that happen to take place in the areas where the brushes pass over the spaces in the commutator. Therefore, BLDC motors are often considered preferable in applications where it is important to avoid electrical noise.

- High efficiency

- Reduced motor size

- Superior thermal characteristics

- Lightweight

- Longer lifetime

- No maintenance due to lack of brushes

- No sparking

- Steady operation

- Variable speed

- Excellent controllability

- High output power-to-size ratio

- Higher speed range

- Lower electric noise generation

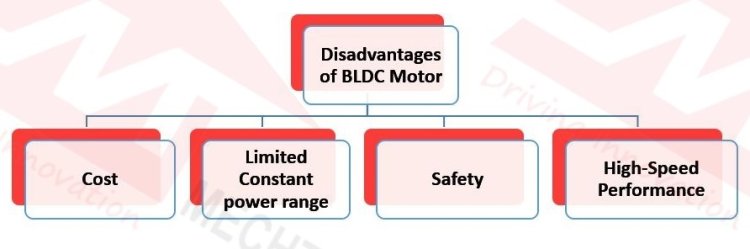

Disadvantages of BLDC Motors

The cost of a BLDC motor is relatively higher when compared to a conventional brushed DC motor. The electronic controller also elevates the overall cost of the complete setup, as in a traditional motor. A less expensive mechanical commutation setup involving brushes is used. When a BLDC motor is operated at low speed, slight vibrations take place during low-speed rotation. However, the vibrations are reduced at high speed.

Due to the inherent natural vibration frequency of the BLDC motor, sometimes this natural frequency is capable of matching or coming closer to the vibration frequency of the body or plastic parts, resulting in the occurrence of a phenomenon known as resonance.

However, this resonance can be minimised by adjustment. The resonance phenomenon is commonly observed in various BLDC motor-based devices.

The brushed DC motors are easy to operate as they have simple wiring. The positive terminal is connected to the positive wire, and the negative terminal is connected to the negative wire, and the motor starts rotating. However, in the case of a BLDC motor, the wiring and operation of the motor are not that smooth and effortless. This is because of the involvement of electronic control and its connection to all electromagnets. For Better Understanding, check out the below diagram

A large constant power range is important for achieving high vehicle efficiency. A BLDC motor can't achieve a maximum speed greater than twice the base speed. During the manufacturing process of the BLDC motor, it might result in being dangerous because the large rare earth permanent magnets can attract scattered metal objects.

In case of a vehicle crash, if the wheels spin freely and the motor is still excited by permanent magnets, high voltages will appear at the motor terminals. This can endanger the passengers or rescuers.

The permanent magnet can be demagnetised by applying a huge reverse magnetomotive force and increasing the temperature. The critical demagnetisation force is distinct for each permanent magnet material. Surface-mounted motors of permanent magnets fail to achieve high speeds. This is because of the limitation of the mechanical strength of the assembly between the rotor yoke and the permanent magnets.

- Cost

- Limited Constant power range

- Safety

- Demagnetization

- High-Speed Performance

Applications of BLDC Motors

Considering the long list of advantages, BLDC motors can be used in numerous applications, ranging from automotive to industrial applications. They can be used in medical equipment, home appliances, building controls, and industrial automation. They can also be used to drive vacuum machines. These brushless motors can also be used to spin hard disc drives.

Here, their durability keeps the drives operating dependably over the long term. The power efficiency of these motors contributes to energy reduction in an area where this is becoming increasingly important. Some applications that use the BLDC motors are :

- Consumer Electronics

- Transport

- Heat and Ventilation

- Industrial Engineering

- Model Engineering

Mechtex BO32(6W) is a High-Speed BLDC Motor with 9280 RPM Speed and 0.69 cNm Torque. It offers advantages such as high reliability, efficiency, and low maintenance, which makes them suitable for industries such as Solar tracking & cleaning systems, and electric vehicles.

Conclusion

BLDC motor plays a very significant role in the advancement of motor technology as it offers numerous advantages over traditional brushed motors. Its construction is simple and consists of a stator, rotor, and positioning sensor, such as a hall sensor, for accurate control.

Its advantages such as high efficiency, durability, and low noise generation, make suited for various industrial applications. Other advantages such as providing speed, steady operation, and excellent controllability, provide an edge over the brushed motor.

Despite numerous advantages, there are some drawbacks of a brushless DC motor such as high cost, complex electric control, and high maintenance cost. Features such as simple construction, high speed, low noise, and accurate position control make it a revolutionized and integral part of modern systems and devices.