Introduction to Synchronous Motors: Working, Types & Applications

A complete introduction to synchronous motors with diagrams, working principles, characteristics, and real-world uses.

What is a Synchronous Motor

A synchronous motor is an electric motor that will run at a synchronous speed, and convert the electrical energy into rotational power.

There are two main types of synchronous motors: Non-excited and excited synchronous motors. Non-excited synchronous motors have rotors that align with the magnetic field to rotate the motor. While excited synchronous motors have an external DC power source to rotate the motor.

Synchronous motors are different from asynchronous motors where the rotor rotates at a slower speed than synchronous motors. Synchronous motors are used in various applications such as power generation plants, industrial applications, consumer electronics, and many more.

Construction of Synchronous Motor

Synchronous motors are a type of electric motor that operates on the principle of synchronism with the magnetic field, where the speed of the motor is directly related to the frequency of the alternating current (AC) power supply. The different parts of synchronous motors work together to make these motors highly efficient and reliable for many industrial processes.

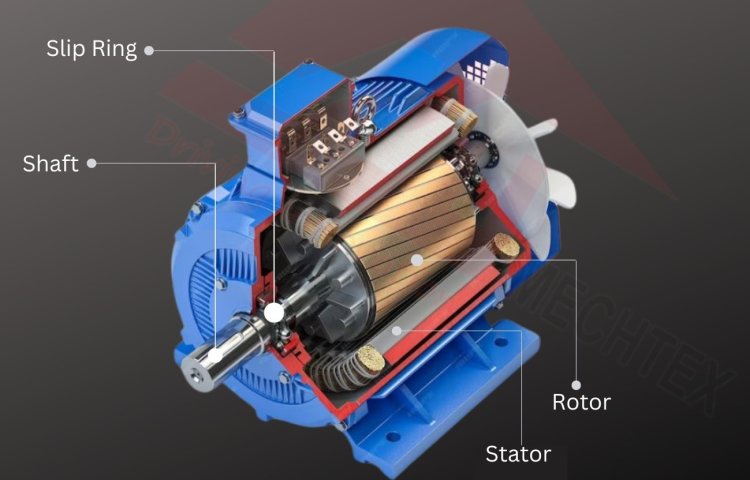

A synchronous motor consists of the following parts :

- Stator

It is a static part made of silicon-steel stampings having internal slots.

- Stator winding

It is a 3-phase star or delta-connected super-enamelled copper winding inserted in the stator slots.

- Rotor

The cylindrical part with poles on the surface. It is also made of silicon steel stampings.

- Rotor winding

Enamelled copper winding is put on the poles and excited by the DC supply received from the exciter.

- Exciter

It is a small-capacity DC shunt generator generally mounted on the same shaft of the rotor and when moving generates a DC supply to be fed to the rotor winding.

- Slip-rings and brushes

There are two slip-rings made of phosphor bronze fitted on the shaft. Two carbon brushes are kept touching the slip-ring via this arrangement, the rotor is fed by DC obtained from the rotating exciter.

Working Principle of Synchronous Motor

A synchronous motor is a type of AC motor that works on the principle of electromagnetic fields. The working of a synchronous motor is divided into three stages: excitation, synchronisation, and steady-state operation.

When a 3-phase supply is connected to the stator winding, a rotating magnetic field is produced by the stator. It rotates at a synchronous speed. Exciter produces DC voltage which is supplied through brushes and slip-rings to the field winding of the rotor. Thus rotor poles are formed.

Check out a Video by "Lesic" for an Inside view of the Working of a Synchronous Motor

Similar poles try to repel each other and hence rotor poles are repelled by stator poles and the rotor tries to rotate in an anti-clockwise direction. Now, as the stator poles are also changing their position (rotating field), after the half revolution, the upper part of the stator will form an S pole and the N pole will be at the bottom. Meanwhile, the rotor’s N pole reaches up to the bottom.

Since the stator N pole is formed at the bottom, there is a force of repulsion and the rotor tries to rotate in a clockwise direction. Again after the half revolution, the stator poles will change their position and the rotor will try to rotate in an anticlockwise direction. Due to the inertia of the rotor, the rotor will not rotate at all. There is no unidirectional torque and hence the synchronous motor is not self-starting.

Also Read

Why Synchronous Motor is not Self-Starting

Advantages of Synchronous Motor

- It can be operated at any desired power factor (unity, leading, or lagging) by changing excitation.

- It can be used for power factor correction.

- It can be constructed with air gaps that are wider than that in induction motors. This makes it more stable mechanically.

- Electromagnetic power varies linearly with the voltage in such motors.

- It offers higher efficiency, usually more than 90%, in the case of low-speed and unity power factor applications.

Mechtex MTR7a is a 48V 1-phase synchronous motor. It offers operating voltage options of 12V, 24V, 48V, 110V, and 230V with 100% duty cycle.

Disadvantages of Synchronous Motor

- Since there is no unidirectional torque, it is not self-starting.

- It requires frequent maintenance.

- An external DC source is required to provide excitation.

- It required additional damper windings.

- Hunting (surging or phase swinging) occurs if there is a sudden change in load.

Also Read

Applications of Synchronous Motor

Conclusion

A synchronous motor is an electric motor that converts electric energy into mechanical energy and runs at synchronous speed. Its working relies on the principle of interaction between the rotating magnetic field of the rotor and stator. Rotor poles repel each other with the help of a stator and move in the anti-clockwise direction.

Synchronous motors face the challenge of not self-starting due to the absence of uni-directional torque. Thus, several methods are used to start a synchronous motor such as installing a damper winding, using pony motors, using an exciter as a DC motor, or connecting it with a DC generator.

It requires frequent maintenance such as air gap should be checked, the bearing should be greased, the Insulation resistance of the windings should be checked, and many others. Despite several challenges and frequent maintenance requirements, synchronous motors play various crucial roles in applications where precision and power are required.

Do you need your application to work with high efficiency and at low operating costs? Mechtex synchronous motors are the perfect solution for your needs. Our synchronous motors have AC supplies with constant speed. They also have low operating costs with a long life span. If you want your application to work with high efficiency, explore our range of AC synchronous motors. We customize synchronous motors with different types of gearboxes for your needs.