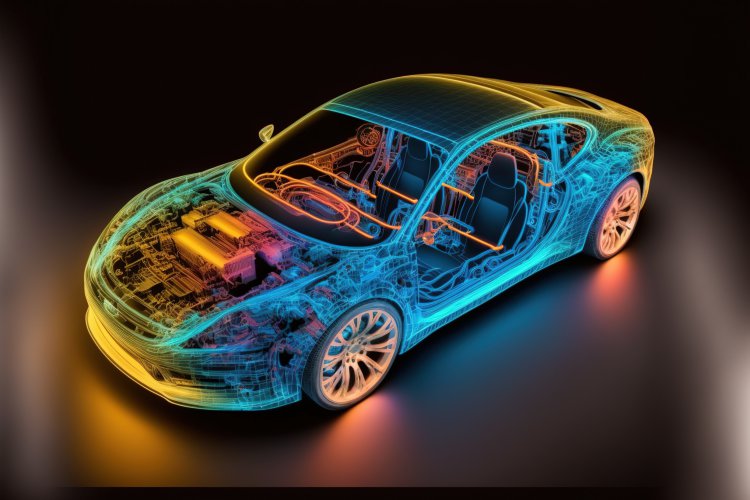

Mechtex has established a strong reputation globally for delivering dependable and high-torque BLDC motors to varied industries for the past 12 years. Our BLDC motors are known for their superior efficiency, high torque, and precise speed control, making them an ideal solution for applications that require reliable performance and energy efficiency.

Mechtex is a leading BLDC motor manufacturer in India and has been in existence for over 55 years. We manufacture 3-phase BLDC motors with different speeds, torque, and voltage combinations. We have 12V BLDC Motor, 24V BLDC Motor, 36V BLDC Motor and Outrunner BLDC Motor with speeds ranging from 1,000 RPM to 10,000 RPM and torque ranging from 0.3 Ncm to 120 Ncm.

To further enhance the performance of Mechtex BLDC motors, we offer a variety of Spur Gearboxes and Planetary Gearboxes solutions. These gearboxes are engineered for durability, precision, and compatibility with numerous applications. We also offer extensive customisation options, including custom shafts, mounting configurations and other integrations such as BLDC Motor Drivers, allowing you to tailor our motors to meet specific application requirements with affordable prices for bulk requirements.

Our motors offer the following characteristics:

Mechtex BLDC motors are widely used in applications such as industrial automation, Renewable Energy Systems, HVAC systems, robotics, medical devices, vending machines, drones, and more. Combined with our advanced gearbox options, Mechtex BLDC gear motors offer the high torque, efficiency, and customisation required to meet the challenges of modern industrial applications.

Enables faster acceleration, better performance, and increased efficiency.

Enhancing efficiency, stability, and reliability of motor in various applications

Help to operates more effectively and conserve less power to provide the same output performance

Increase Motor Life Span and Ensures uninterrupted performance of motor

• MECHTEX does not sell OEM (Original Equipment Manufacturing) parts direct to consumers.

• If you are inquiring about non-Aftermarket parts, please contact your application/device manufacturer or local service dealer.

• Our technical team will contact you within 24 to 48 working hours, either by email or telephone. Thank you for your understanding in advance.

EL-108, Electronic Zone, Mahape TTC Industrial Estate, Navi Mumbai - 400709, Maharashtra India