Understanding the Hybrid Stepper Motor: Introduction, Working & Applications

A hybrid stepper motor is a type of stepper motor that combines the features of both permanent magnet stepper motor (PM) and variable reluctance (VR) stepper motors. Its working principle involves the interaction of electrical pulses and magnetic fields to produce rotational movement with discrete steps.

What is a Hybrid Stepper Motor

A hybrid stepper motor is a type of motor widely used in various applications, ranging from industrial machinery to consumer electronics. They combine the features of both permanent magnet stepper motor (PM) and variable reluctance (VR) stepper motors, offering high torque, precise positioning, and excellent resolution.

Hybrid stepper motors derive their name from their unique design that incorporates elements of both PM stepper motors and VR stepper motors, resulting in a hybrid configuration. Unlike traditional stepper motors that use either PM stepper motor or VR stepper motor features, hybrid stepper motors utilise a combination of these motors to optimise their performance.

One of the key advantages of hybrid stepper motors is their ability to provide greater accuracy and smoother operation compared to other types of stepper motors. This is achieved through their unique construction and control mechanism, which enables precise control over the motor's position and speed.

Hybrid stepper motors are highly versatile and find applications in a wide range of industries, including robotics, CNC machines, 3D printers, medical devices, and automotive systems. Their ability to deliver high torque at low speeds makes them particularly well-suited for applications that require precise motion control and positioning.

In addition to their high versatility, hybrid stepper motors are also known for their reliability and durability, making them a popular choice for demanding industrial environments. With advancements in technology, hybrid stepper motors continue to evolve, offering improved efficiency, higher torque density, and enhanced functionality to meet the growing demands of modern applications.

Also Read:

What is Permanent Magnet Stepper Motor?

Working of Hybrid Stepper Motor

The working principle of hybrid stepper motors involves the interaction of electrical pulses and magnetic fields to produce rotational movement.

Like other stepper motors, hybrid stepper motors consist of a stationary part called the stator and a rotating part called the rotor. The stator contains multiple electromagnets arranged in a circular pattern, while the rotor is typically made up of teeth or poles.

Check out the video below by "RealPars" to see how hybrid stepper motors work in different applications

Hybrid stepper motors have multiple phases, with each phase having its own winding. These windings are typically arranged in a bipolar configuration, meaning there are two wires per phase.

When a current flows through a winding, it generates a magnetic field that interacts with the permanent magnets in the rotor. By energising the windings in a specific sequence, the magnetic fields produced by the stator attract or repel the rotor's magnets, and inducing it to move in discrete steps.

The step angle of a hybrid stepper motor is determined by the number of teeth or poles on the rotor and the arrangement of the stator windings. Typical step angles of a hybrid stepper motor range from 0.9 to 1.8 degrees per step, offering precise control over rotational motion.

Advanced stepper motor drivers support micro-stepping, which further divides each full step into smaller increments. Microstepping allows for smoother motion and improved positional accuracy by energising the windings with varying current levels between full steps.

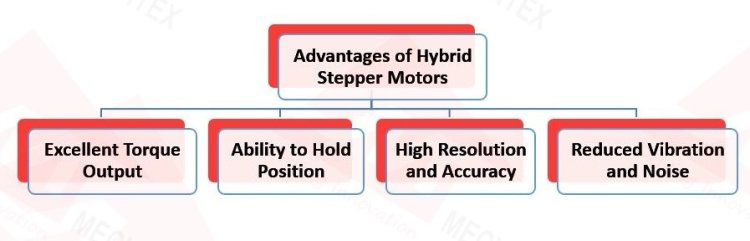

Advantages of Hybrid Stepper Motors

The most popular stepper motors in the market are the hybrid stepper motors as they offer the best performance as compared to the VR stepper motor and PM stepper motors. Hybrid stepper motors offer several advantages over other types of motors, making them a popular choice in various applications.

- Excellent Torque Output

One of the key advantages is their excellent torque output, which allows for precise control and positioning. This makes hybrid stepper motors ideal for applications that require high levels of accuracy, such as robotics, CNC machines, and 3D printers.

NEMA 17 hybrid stepper motors are commonly used in these applications due to their compact size, high torque, and reliable performance in a variety of precision tasks.

- Ability to Hold Position

Another advantage of hybrid stepper motors is their ability to hold position without the need for external feedback devices. This inherent position-holding capability eliminates the need for additional sensors and simplifies the control system. Additionally, hybrid stepper motors are relatively easy to drive and can be controlled using simple digital signals, making them suitable for a wide range of applications.

- High Resolution and Accuracy

Hybrid stepper motors typically have a step angle of 1.8 degrees or even smaller, resulting in high angular resolution. Some designs may incorporate micro-stepping, allowing for even finer resolution and smoother motion. Mechtex hybrid stepper motors can offer as low as 0.007 degrees step angle with our range of spur and planetary gearboxes. This high resolution makes them suitable for applications that require precise positioning.

- Reduced Vibration and Noise

Hybrid stepper motors, especially when used with micro-stepping drivers, can exhibit reduced vibration and noise levels during operation. Microstepping subdivides each full step into smaller steps, resulting in smoother motion and less audible noise.

The hybrid stepper motor also comes with a handful of shortcomings, the biggest one being its complex design. Other disadvantages include high resonance and lower torque at high speeds, higher power consumption, larger size, and more weight, as compared to other types of stepper motors.

Also Read:

Advantages and Disadvantages of Stepper Motor

Conclusion

Hybrid stepper motors are a remarkable innovation in the field of motion control. Their unique design, precise movement, and excellent torque output make them an essential component in numerous applications. By understanding the principles behind their operation and considering the factors that impact their performance, engineers, and designers can harness the full potential of hybrid stepper motors

Whether you are working on robotics, CNC machines, 3D printers, or other motion control systems, hybrid stepper motors offer the precision and control necessary for success. By selecting the right motor, optimizing its operation, and troubleshooting any challenges that may arise, you can ensure optimal performance and reliable motion control.