Components of Brushless Drone Motors and How They Work

Drones commonly use brushless motors for their efficiency and durability. The BLDC motor comprises a stator, rotor, copper windings, magnets, bearings, and a controller. These brushless motors work with a combination of electromagnetism and a control system.

"In the world of drones, brushless motors are the driving force of innovation"

Drones, also known as unmanned aerial vehicles (UAV), have become increasingly popular in recent years for their various uses such as aerial photography, package delivery, and even military operations. These flying machines are powered by motors specifically designed to meet the demands of their unique flying capabilities. Let us dive into the inner workings of these motors, their components, and how they work together to make drones fly.

Components of Brushless Drone Motors

Drones commonly use BLDC drone motors. These motors are electronically controlled and provide the necessary thrust to propel the drone through the air. These motors provide smoother operation and higher power output, making them ideal for drone applications for their precise control and performance.

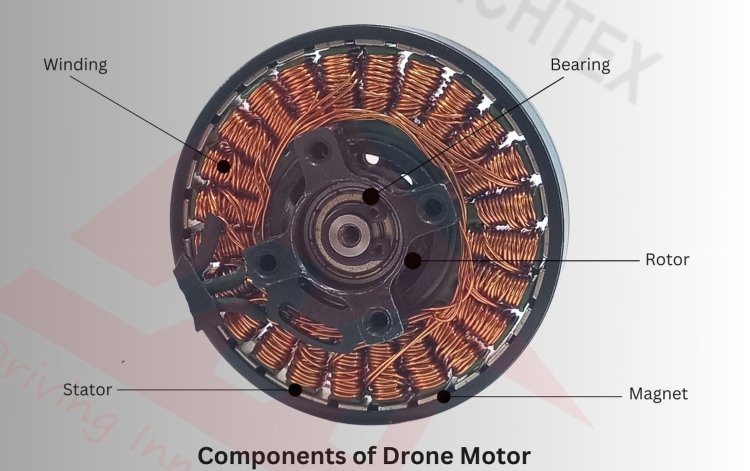

There are several components of brushless drone motors that play a crucial role in the function of the drone are as follows:

- Stator

It is the stationary part of the motor. It consists of coils of wire known as stators winding. These coils are made up of copper and are responsible for generating the magnetic field. When electric current passes through these windings, it creates a magnetic field.

- Rotor

It is the rotating part of the motor. It consists of permanent magnets that interact with the magnetic field produced by the stator and cause the rotor to rotate. The design and construction of the rotor impact the drone's performance and efficiency.

- Bearings

Bearings are round objects designed to reduce friction between parts of drone motors and allow the rotor to rotate smoothly. Different types of bearings are used in drone motors, but the most common are ball bearings and sleeve bearings.

- Controller

The controller is an important component of every brushless drone motor, as it is responsible for controlling the speed and direction of the drone. When it receives the signal from the pilots, it adjusts the power and timing of the brushless drone motor and allows the drone to move in different directions.

For example, if a pilot wants to turn the drone to the left, it adjusts the power and timing of the left motor and allows the drone to move left.

Also Read

A Comprehensive Guide On Drone Motors

Working of Brushless Drone Motors

Brushless motors used in drones work through a combination of electromagnetism and a control system. The motors consist of two primary components: stator and rotor. The stator consists of electromagnetic coils while the rotor consists of permanent magnets. The proper arrangement of these components enables the conversion of electrical energy into mechanical energy for smooth operation.

The working of a brushless motor starts with a signal from the flight controller. The flight controller monitors the drone status and pilot’s input to determine the speed and direction required by each motor. The flight controller then sends these speed and direction commands to the electronic speed controller(ESC).

Upon receiving the signal, the ESC then reads the signals to understand the desired speed and direction of the motor. Once the ESC understands the signal, it adjusts the flow of electric current into the electromagnetic coils of the brushless motor.

As a result, the rotating magnetic field is generated and interacts with the fixed magnetic field produced by the rotor. This interaction creates electromagnetic force and the motor starts to spin.

To get a Visual Representation of How Brushless Motor Works, watch the video posted by "Ayush" on YouTube.

The incorporation of sensors such as hall effect sensors, enhances the working of brushless drone motors. These sensors provide feedback to ESC, enabling the monitoring of the rotor’s position and speed. This feedback facilitates precise control and enhances the performance and efficiency of brushless drone motors.

The power for brushless drone motors is supplied by lithium polymer batteries. The combination of lithium polymer batteries and brushless motors provides a high power-to-weight ratio, which is crucial for drone flight and performing agile manoeuvres.

In conclusion, brushless drone motors epitomise the synergy between advanced electromechanical principles and cutting-edge control systems. Their efficiency, reliability, and precise performance make them crucial components in drones.