Mechtex has established itself as a trusted provider of high-performance hybrid NEMA stepper motors for over 8 years, serving diverse industries such as automation, medical equipment, robotics, and more. Our NEMA hybrid stepper motors are renowned for their precise movement and reliability, making them the ideal solution for applications requiring accurate positioning and speed control.

Mechtex is a motor & gearbox supplier with 55+ years of experience. We supply different types of NEMA motors with different voltages and step angles. Our motors like NEMA 17 stepper motor, NEMA 23 stepper motor, and NEMA 24 stepper motor range between 12V to 48V with a 1.8-degree step angle.

Our NEMA hybrid stepper motors can also integrate different types of planetary gearboxes. These gearboxes are designed for durability, precision, and flexibility, and we offer extensive customisation options to meet your specific needs, such as different stack heights, different types of shafts, and multiple micro-stepping drivers with these motors as per the requirement.

Our motors offer the following characteristics:

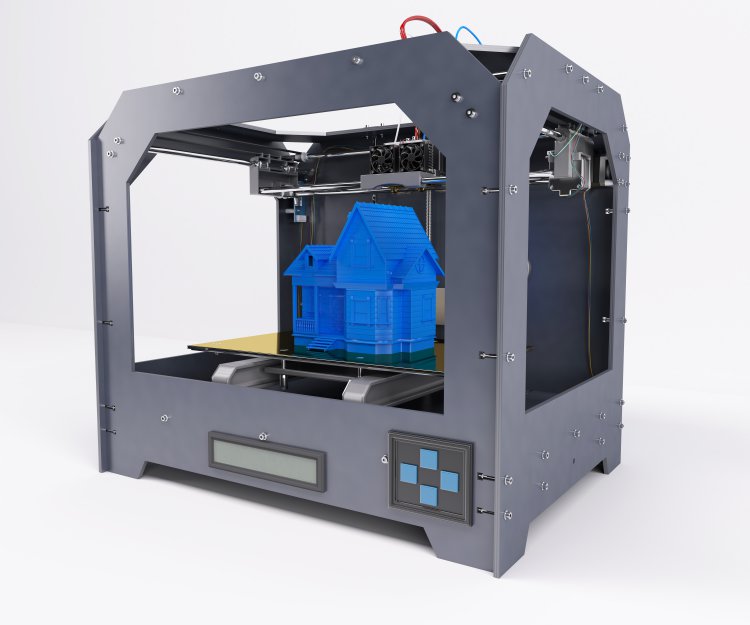

Common applications of our NEMA hybrid stepper motors include 3D printers, CNC machines, medical equipment, robotics, textile machinery and industrial automation applications. Paired with our advanced gearbox solutions, Mechtex stepper motors offer the precision, reliability, and efficiency required for a range of industrial applications.

Ensures precise and stable positioning to prevent undesired movement of motor

Provide more accurate movement enable precise control and smoother performance of motor

Allows precise and controlled movements, ideal for slow and accurate motion applications

It enhance portability, and provide efficient performance for applications

• MECHTEX does not sell OEM (Original Equipment Manufacturing) parts direct to consumers.

• If you are inquiring about non-Aftermarket parts, please contact your application/device manufacturer or local service dealer.

• Our technical team will contact you within 24 to 48 working hours, either by email or telephone. Thank you for your understanding in advance.

EL-108, Electronic Zone, Mahape TTC Industrial Estate, Navi Mumbai - 400709, Maharashtra India