Brushed vs Brushless Drone Motors: Which One Should You Choose

Brushed motors are cost-effective and beginner-friendly, while brushless motors deliver superior performance, and high efficiency, which makes them the preferred choice for professional and high-performance drones. By understanding each motor type, one can make an informed decision that aligns with the drone.

Drones are revolutionising industries from photography to agriculture, delivery and surveillance. At the heart of every drone, there is a drone motor responsible for converting electrical energy into mechanical force to propel the drone. The choice between brushed and brushless drone motors significantly impacts the drone's performance, efficiency and longevity. In this blog, we will delve into the fundamental differences, advantages, and factors to consider when selecting the right motor for your drone.

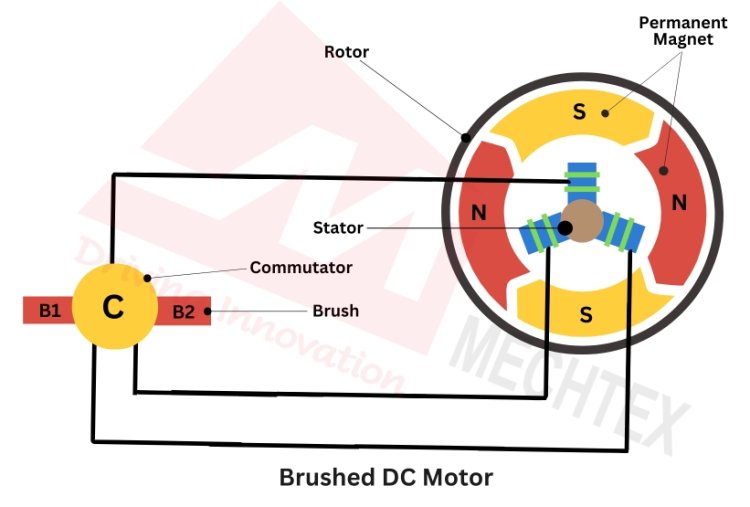

What is Brushed Motors?

Brushed motors are among the simplest and most traditional types of motors found in entry-level drones. They operate using direct current and rely on mechanical commutation facilitated by brushes and commutators.

While they have a simple design and are cost-effective, they differ from BLDC motors for drones, which utilise electronic commutation, offering lower efficiency and shorter lifespans in comparison. Despite this, brushed motors remain a practical choice for drones requiring basic functionality.

A brushed motor consists of a stationary part called stator and a rotating part called rotor. The stator consists of permanent magnets and the rotor consists of wound coils. The rotor coils are connected to a segmented commutator.

When a DC voltage is applied, current flows through the brushes to the commutator and into the rotor winding. The current generates a magnetic field which interacts with the stator's permanent magnetic field to produce torque. The commutator reverses the current direction in the rotor windings as it rotates, to ensure continuous torque in the desired direction.

Advantages of Brushed Motors

- Cost Effective

Affordable due to simple design and manufacturing process.

- Easy to Use

They require less sophisticated electronic controllers, making them easy for beginners to use.

- Availability

Widely available and easy to replace.

What is Brushless Motors?

Brushless motors are the powerhouse of modern drones renowned for their efficiency, durability and performance. Unlike brushed motors, brushless motors for drones eliminate the physical brushes and rely instead on electronic commutation to control the current flow through their windings. This design reduces wear and enhances reliability.

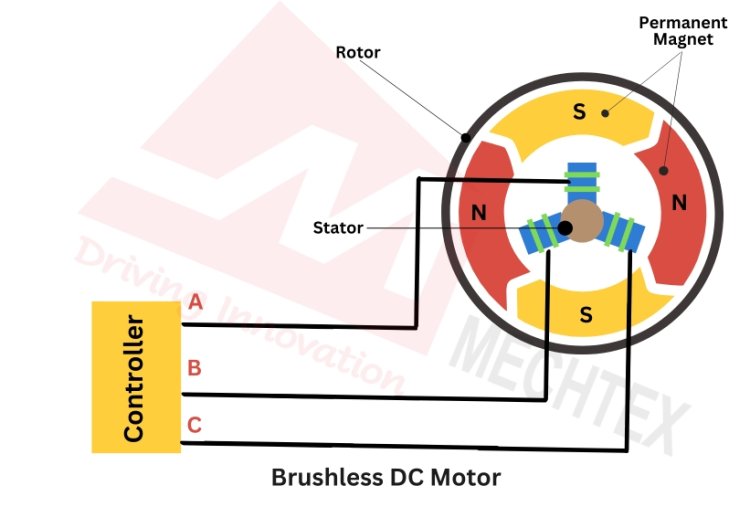

A brushless motor consists of a stator, rotor and electronic speed controller (ESC). Stator is the stationary part of the motor. It consists of multiple windings arranged in slots. It generates the magnetic field required for rotation. Rotor is the rotating part of the brushless motor. It is equipped with permanent magnets that interact with the stator’s magnetic field and rotate. ESC is an external device that manages the commutation process by controlling the current flow in the stator windings.

BLDC drone motors function through the interaction between the stator’s magnetic field and the rotor’s permanent magnet. The ESC sequentially energises the stator windings and creates a rotating magnetic field. This field attracts and repels the rotor’s permanent magnet and causes the rotor to spin. The ESC continuously monitors the current flow and adjusts it to maintain precise speed and torque to ensure smooth and efficient operation.

Advantages of Brushless Motors

- Durability

More durable as there is no physical contact between moving parts which results in less wear and tear.

- High Efficiency

Minimal energy loss due to the absence of friction ensures high efficiency.

- Performance

Provide greater torque, speed, and thrust, ideal for high-performance drones.

- Precision

Provide better control for stable flight and advanced manoeuvres.

Also Read

Why BLDC Motors Are Used In Drone Technology

Brushed vs Brushless Motors for Drone

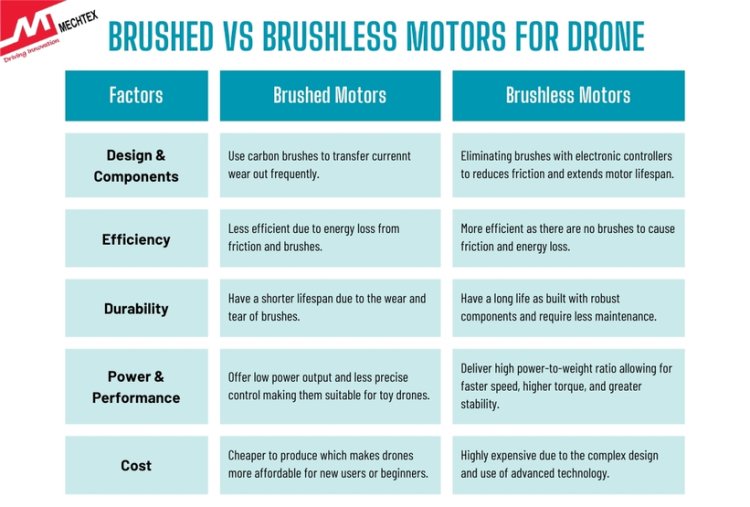

When choosing between brushed and brushless motors for drones, several key factors play a significant role in performance, efficiency, and durability. Some key factors are:

Design and Components

- Brushed DC Motors: Use carbon brushes to transfer electrical current to the rotor. The brushes wear out frequently and require maintenance.

- Brushless Motors: Eliminate brushes and use electronic controllers to direct the current to the rotor. This design minimises friction and improves the lifespan of the motor.

Efficiency

- Brushed DC Motors: Less efficient due to energy loss in friction from brushes. They tend to generate more heat and reduce battery life.

- Brushless Motors: More efficient because there are no brushes to cause friction. This leads to lower heat generation and extended battery life.

Durability

- Brushed DC Motors: Have a shorter lifespan due to the wear and tear brushes, especially under heavy usage.

- Brushless Motors: Have a long life since there are no brushes to wear. Components are more robust and require less maintenance.

Power and Performance

- Brushed DC Motors: Offer low power output and less precise control making them suitable for toy drones or low-cost drones.

- Brushless Motors: Deliver high power-to-weight ratio allowing for faster speed, higher torque, and greater stability in every flight. Ideal for modern drones.

Cost

- Brushed DC Motors: Cheaper to produce which makes drones more affordable for new users or beginners.

- Brushless Motors: Highly expensive due to the complex design and use of advanced technology which pays off with better performance and durability.

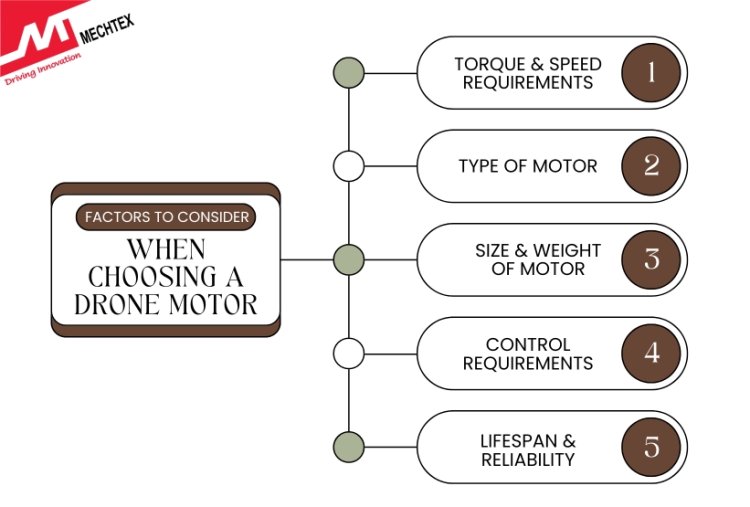

Factors to Consider When Choosing a Motor

When choosing drone motors for any drone, several factors must be considered to ensure optimal performance, efficiency, and cost-effectiveness. Key factors include:

- Torque and Speed Requirements

Determine the required torque and speed for the drone. Drone motors have different torque-speed characteristics for different types of drones.

- Motor Type

Choose the appropriate drone motor type for your drone. Common types of drone motors include brushed motors and brushless motors. Each type offers specific advantages in terms of control, efficiency, and precision.

- Size and Weight

The physical size and weight of the drone motor should match the constraints of the drone. Smaller or lighter motors may be required in space-constrained or weight-sensitive applications, like drones.

- Control Requirements

Some drone motors such as brushless motors require specific controllers such as ESCs or drivers for precise operation while some drone motors such as brushed motors operate without any control system. Select the appropriate motor which is compatible with the available control system of the drone.

- Lifespan and Reliability

Asses the drone motor's expected lifespan and reliability based on its usage. Higher durability may be required for industrial or mission-critical drones.

When to Choose Brushed Motors?

- Beginners

Ideal for beginners or new users looking for an affordable solution.

- Short-Term Use

Suitable for applications where the motor's lifespan is not a concern.

- Lightweight Drones

Adequate for small drones with minimal performance.

When to Choose Brushless Motors

- Professionals

Preferable for aerial photography, mapping, and industrial applications.

- Heavy Payloads

Suitable for drones carrying cameras, sensors and other payloads.

- Long Flight Times

Necessary for drones like surveillance and delivery drones which require long flight time for their operation.

- Advanced Maneuvering

Required for racing drones and other drones that perform complex aerial stunts.

Conclusion

The choice between brushed and brushless drone motors depends on the drone’s application, budget, and performance needs. While brushed motors are cost-effective and beginner-friendly, brushless motors deliver superior performance, longevity, and efficiency, making them the preferred choice for professional and high-performance drones.

By understanding each motor type, one can make an informed decision that aligns with its goals, whether it’s exploring drone technology as a hobby or executing precision-driven aerial tasks.