Applications of Synchronous Motors: Industry Uses, Power Factor & Precision Drives

Explore the key applications of synchronous motors from constant speed industrial drives like pumps, compressors, fans and conveyors to power factor correction, precision timing, and automation systems.

What is a Synchronous Motor?

A synchronous motor is an AC motor that operates at a constant speed synchronised with the frequency of supply. Unlike induction motors, which experience a slip and cannot operate at synchronous speed. The synchronous motor rotates with the magnetic field and maintains its constant speed. This makes them ideal for applications that require constant and precise speed control.

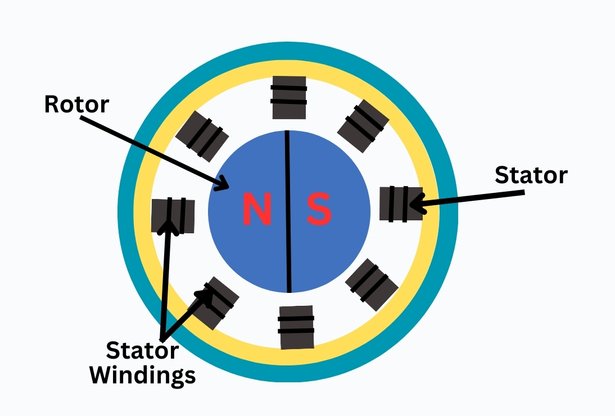

The construction of a synchronous motor includes two main parts: stator and rotor. The stator is the stationary part of the motor made up of a laminated steel sheet and consists of three-phase winding. The rotor is the rotating part of the motor. It can be either a salient pole or a non-salient pole and consists of permanent magnets. It generates a magnetic field and transmits mechanical output to the load.

When AC power is supplied to the stator’s winding it creates a rotating magnetic field (RMF). The rotor is energised with the DC current and creates its own magnetic field. The rotor synchronises with the rotating magnetic field of the stator and rotates at the same speed as the stator. It is known as synchronous speed.

The synchronous speed of the synchronous motor can calculated with the help of the following formula:

Ns = 120xf/P

Where,

Ns = Synchronous Speed (in RPM)

f = Supply frequency (in Hz)

P = Number of poles

The synchronous motor continues to run at the synchronous speed as long as it remains loaded within its rated capacity.

Synchronous motors have several advantages compared to other motors. They have the ability to maintain a constant speed regardless of load variations. Also, they are highly efficient and can operate at a leading power factor, which helps in power factor correction, making them a valuable asset in industrial applications. Additionally, they are suitable for high-power applications where both efficiency and constant speed are critical.

Also Read

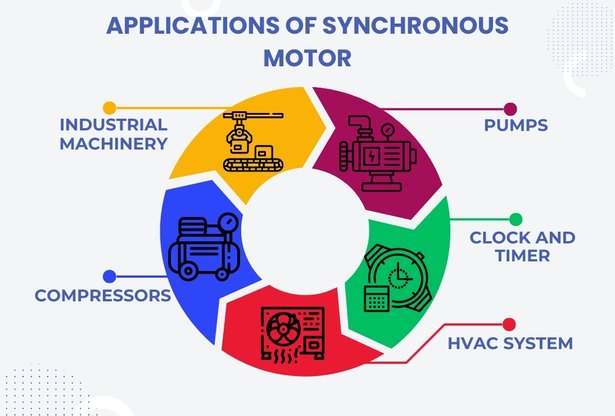

Applications of Synchronous Motor

Features such as precise speed control, high torque at low speed, power factor correction, and the ability to maintain synchronous speed enhance the performance and efficiency of the systems and make synchronous motors vital components in driving systems and applications across various sectors to ensure reliable and efficient operation.

Some of the common applications of synchronous motors are:

The synchronous motor plays a pivotal role in driving industrial machinery and its processes with precision and efficiency. These motors are commonly used in conveyor systems, mixers, extruders, machine tools, printing presses, and packaging machinery.

Synchronous motors have the ability to maintain synchronization between the rotating magnetic field of the stator and the magnetic field of the rotor. It helps synchronous motors to provide precise speed control and ensure consistent processes with high-quality output.

Whether it is regulating movement on the conveyor, blending ingredients in the mixer, or shaping the material in extruders synchronous motors provide torque and speed control to ensure optimal performance.

In printing presses and packaging machinery, synchronous motors offer accurate and synchronized operation, resulting in high-quality finished products.

Mechtex MTRD4b is a 7W synchronous motor with operating voltage options spanning 24V, 48V, and 110V. Its precise synchronous motion control makes it ideal for industries such as Industrial Machinery and any industry requiring accurate motion control.

- Compressors

Synchronous motors are widely used in compressors due to their ability to provide high torque at low speed, precise speed control, and leading power factor.

In compressors, synchronous motors drive the compression mechanism, to increase the pressure of gases and air in various applications such as refrigerators, air conditioners, and industrial machinery.

These motors allow precise control over the rotational speed of the compressors and ensure efficient operation by maintaining synchronization with the power supply. It helps compressors to operate at the desired compression ratio and ensure efficient performance with minimizing energy consumption.

- Pumps

Synchronous motors are the integral component of the pump system. These motors drive the rotating impeller or rotor of pumps to maintain fluid flow in applications.

Synchronous motors offer several advantages to pump systems. Firstly, synchronous motors provide high torque at low speeds and ensure efficient start-up operation, especially when the pump needs to overcome the initial resistance from the lower level.

Additionally, synchronous motors offer precise speed control and allow the pumps to regulate the flow of liquid accurately to applications. It helps pumps to offer reliable performance and ensure energy efficiency in various load conditions.

Mechtex MTR3b synchronous motor offers precise speed control, high starting torque, and versatile voltage options which makes it an excellent choice for various types of pumps.

Synchronous motors are the essential components in HVAC systems by providing precise control and efficient operation in various applications. These motors power the various components of HVAC systems such as fans, compressors, and dampers.

In fans of HVAC systems, synchronous motors ensure precise speed control for optimal speed regulation, temperature, and humidity control in residential and commercial areas.

Similarly in compressors, synchronous motors ensure efficient heating and cooling processes and contribute to temperature regulation and energy efficiency in various environmental conditions.

While in dampers, synchronous motors control the position of dampers and ensure precise regulation of airflow to different zones to ensure optimal temperature control in residential and commercial areas.

Mechtex MTR3a synchronous motor offers precision and reliability in its operation, ensuring efficient and consistent performance which makes it an ideal choice for HVAC systems.

- Clock and Timer

Synchronous motors are the ideal solution for clocks and timers. These motors offer precise rotational speed synchronized with the frequency of the AC power supply.

Unlike asynchronous motors, synchronous motors do not experience slip and ensure consistent and accurate time measurement. This is achieved by synchronizing the rotation of the rotor with the magnetic field of the stator and results in fixed-speed rotation.

This helps clocks and timers to ensure accurate time-keeping over extended periods without any fluctuations.

Additionally, synchronous motors are energy efficient, consume less power during operation while providing the necessary torque to drive the clock mechanism and become an indispensable component of various timekeeping devices.

Conclusion

Synchronous motors have proven themselves an invaluable asset across a wide range of industries and applications due to their exceptional capabilities. They maintain precise speed control, generate high torque, and provide power factor correction which sets them apart from other types of motors.

These unique features make synchronous motors pivotal components in industrial machinery, compressors, pumps, and HVAC systems. Their precise control ensures consistent and reliable performance and leads to high-quality output and enhanced system stability.

As technology continues to advance, the demand for synchronous motors is expected to grow faster and play a pivotal role in powering industrial systems and processes across various sectors for modern-day operation.