How to Choose the Right Drone Motor for Different Applications

A drone motor is a crucial component of a drone that generates thrust and allows it to take flight. Choosing the right drone motor involves factors such as understanding the drone's purpose, and technical aspects of motors which help to select the right drone motor.

Selecting the right drone motor is a crucial step in designing and upgrading the drones. The drone motor directly impacts the performance, efficiency, flight time and payload capacity of the drone. As various types of drone motors are available, understanding their types, and specifications is essential. In this blog, we will help you navigate the types, and key selecting factors to make an informed decision about choosing drone motors.

What is Drone Motor?

A drone motor is a crucial component of a drone that generates thrust and allows it to take flight. It converts electrical energy into mechanical energy to spin the rotor at high speed. The efficiency, power, and control of a drone largely depend upon its type and quality.

A drone motor has several components such as stator, rotor, winding, bearing and shaft. The stator contains copper windings that generate a magnetic field while the rotor holds the permanent magnet interacts with the magnetic field and rotates. Bearings ensure smooth rotation, and the shaft transmits force to the propellers.

Watch the YouTube Video by "The Engineering Mindset" to learn about the working of brushless drone motors.

When electrical current flows through the stator winding, it creates a magnetic field causing the rotor to spin. An ESC (electronic speed controller) regulates power to control speed and direction. This precise control allows the drone to take off, hover, and manoeuvre efficiently.

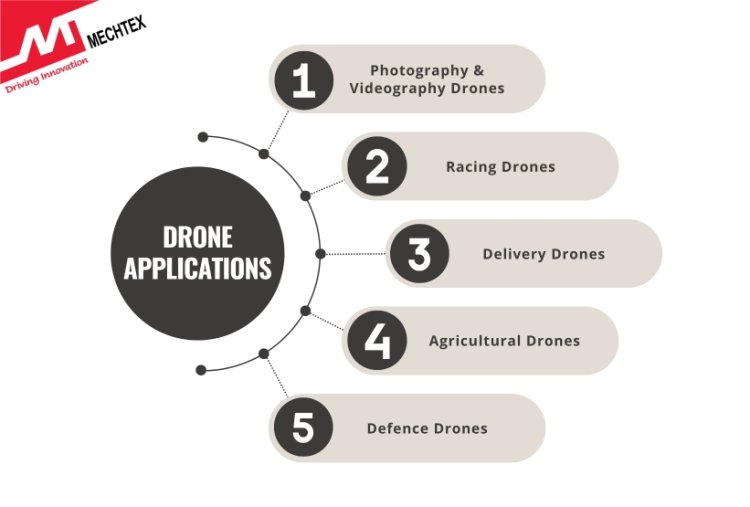

Drone motors are used in various applications, including aerial photography, agriculture, delivery services, military surveillance, and industrial inspections. Selecting the right motor depends on the drone’s purpose, payload, and required flight duration.

Also Read

A Comprehensive Guide on Drone Motors| What they are, their types, and their applications

Types of Drone Motors

- Brushed Drone Motor

Brushed motors use carbon brushes to conduct electricity to the rotor. They are simple, inexpensive, and suitable for small, lightweight drones. However, they have limited efficiency, shorter lifespan, and lower output making them less suitable for advanced applications.

- Brushless Motors (BLDC)

BLDC motors use electronic commutation making them more efficient, durable and powerful. They offer better speed control and higher torque to weight ratio making them ideal for high performance including racing, aerial photography, and industrial applications.

- Inrunner Motors

In inrunner motors, the rotor inside the stator, spins with high RPM. These motors are typically used in high-speed applications where direct drive is not used.

- Outrunner Motors

These motors rotate around the stator, providing higher torque at lower RPM. Due to their superior torque output and efficiency, they are more common in multirotor drones.

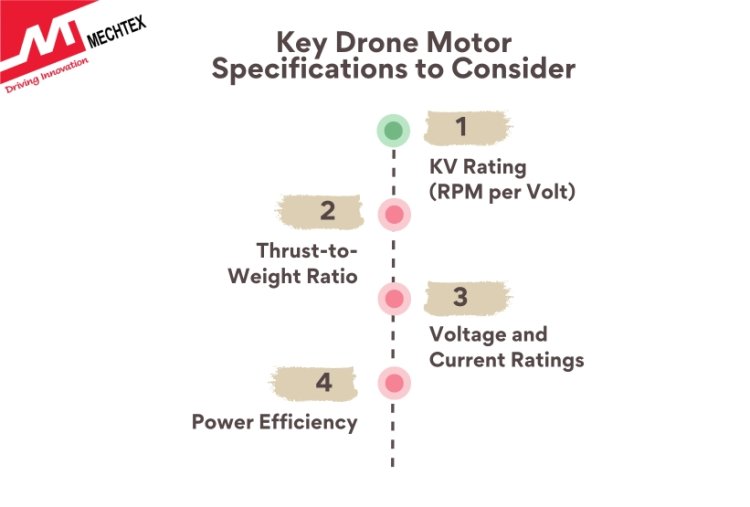

Key Drone Motor Specifications

- KV Rating (RPM per Volt)

KV rating, measured in RPM per volt (RPM/V), indicates the speed at which a motor rotates per applied volt without load.

-

-

-

- Low KV Motors: Suitable for large drones with big propellers. They offer more torque and efficiency for carrying heavier payloads.

-

-

-

-

-

- High KV motors: Ideal for smaller racing drones that require higher speed but lower torque.

-

-

- Thrust-to-Weight Ratio

It is the ratio of drone motors to the total weight of the drone. It determines the drone’s performance, agility, and lift capability. A thrust weight to ratio of 2:1 means the thrust is twice the drone’s weight, enabling stable flight and efficient manoeuvrability.

- Voltage and Current Ratings

Voltage and current ratings define the operational limits of a motor.

-

-

-

- Voltage (V): It indicates the maximum safe voltage for optimal performance, affecting speed and efficiency. Motors are rated for specific operating voltages, commonly 3S (11.1V) or 4S (14.8V) for consumer drones, while professional drones may use 6S (22.2V) or higher.

-

- Current (A): The current rating specifies the maximum current the motor can handle without overheating. Exceeding these ratings can cause overheating, reduced efficiency, or motor damage.

-

-

- Power Efficiency

It is the ratio of a motor's useful output power to the input power. Higher efficiency means less energy is wasted as heat. For drone motors, greater efficiency improves flight time and performance by maximising thrust while minimizing energy consumption.

Choosing the Right Motor for Different Drone Applications

- Aerial Photography and Videography Drones

Aerial photography drones require smooth and stable flight characteristics to capture high-quality images and videos.

-

-

- Motor Type: Require low KV drone motors.

- Propeller Size: Require large diameter propeller for stability.

- Recommended Setup: 4 to 6-cell LiPo batteries with ESC matching the KV rating.

-

- Racing Drones

Racing drones demand high-speed motors with quick response time agility and manoeuvrability.

-

-

- Motor Type: Require high KV brushless drone motor

- Propeller Size: Require small and lightweight propellers.

- Recommended Setup: 4S to 6S LiPo batteries with a high C rating for instant power delivery.

-

- Delivery Drones

These drones used for parcel delivery need to handle heavy payloads and offer extended flights.

-

-

- Motor Type: Require low KV brushless motors

- Propeller Size: Require large propellers for high thrust.

- Recommended Setup: High voltage 6S -12S batteries and high-efficiency drone motors.

-

- Agricultural Drones

These drones are used for spraying pesticides, crop monitoring, and mapping. They require powerful motors with long operational capabilities.

-

-

- Motor Type: Require low KV brushless motors.

- Propeller Size: Require large carbon fibre propellers.

- Recommended Setup: High-voltage 8S-12S batteries with waterproof ESCs.

-

- Defence Drones

Defence drones need to be highly durable, efficient, and capable of carrying payload equipment including surveillance equipment.

-

-

- Motor Type: Require high-end brushless drone motor.

- Propeller Size: Require large-diameter composite propellers.

- Recommended Setup: High-density battery packs or hybrid power sources.

-

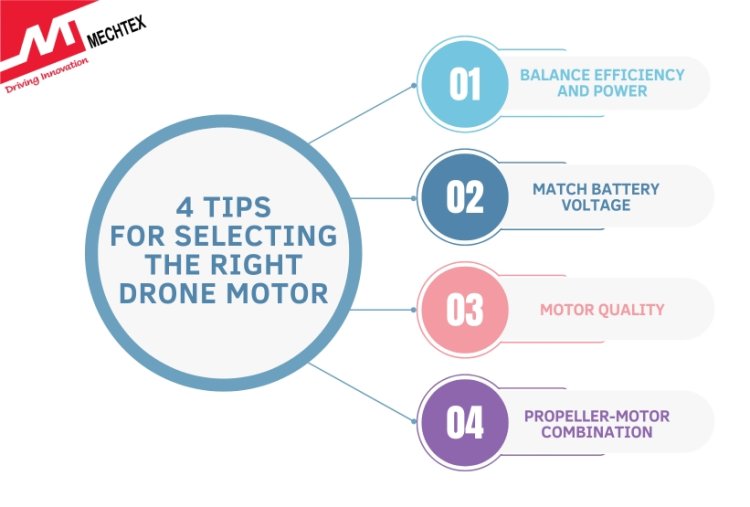

Tips for Selecting the Right Drone Motor

- Balance Efficiency and Power

Choose a drone motor with an appropriate KV rating to balance speed and efficiency based on the application.

- Match Battery Voltage

Ensure the motor KV and battery voltage are compatible for optimal performance.

- Motor Quality

Use high-quality durable motors with efficient cooling and low electromagnetic interference.

- Propeller-Motor Combination

Test different propeller sizes to find the best thrust-to-power consumption ratio.

Conclusion

Choosing the right drone motor is essential for maximizing performance, efficiency, and longevity.

Whether for photography, racing, industrial use, or delivery, selecting a motor based on KV rating, propeller size, efficiency, and specific application needs ensures optimal results.

By understanding the drone's purpose and the technical aspects of motors, one can make an informed decision that enhances the drone's capabilities.