Vibration Control and Balancing in Drone Motors

Learn how to implement effective vibration control and balancing in drone motors to improve flight stability, reduce component wear, and enhance performance in professional drone applications.

In the fast-evolving world of aerial robotics, the efficiency and performance of drone motors directly impact flight quality, durability and payload capacity. One critical yet often overlooked factor is vibration control and motor balancing. Excessive vibrations not only compromise the aerodynamic stability but also lead to premature wear of components.

In this blog, we will explore the causes of vibrations in drone motors, the importance of motor balancing, and the techniques used for vibration control in drone systems, especially in high-performance applications such as mapping, surveillance, and agriculture.

What is a Drone Motor?

A drone motor is the core component that drives the propellers and unmanned aerial vehicles (UAV) to lift, manoeuvre, and fly. Most drones use BLDC motors due to their high efficiency, long lifespan and compact design.

These Brushless DC motors convert electrical energy to mechanical rotation and produce thrust.

Drone motors are designed to deliver high torque at relatively low weight, which is essential for stable flight. These motors are available in two types: outrunner BLDC motor, where the outer casing rotates with the shaft, and inrunner BLDC motor, where the rotor spins inside. Outrunner motors are more common in drones due to their higher torque output at lower RPMs.

The motor’s specifications, such as KV rating, thrust-to-weight ratio, and current draw, must match the propeller size and battery voltage for optimal performance. Additionally, electronic speed controllers (ESCs) are paired with motors to regulate their speed.

Also Read

A Comprehensive Guide on Drone Motors| What they are, their types, and their applications

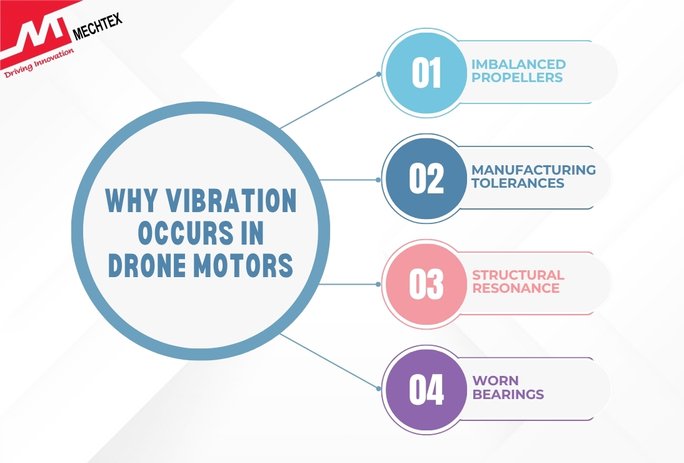

Why Vibration Occurs in Drone Motors?

Vibration in drone motors arises due to multiple factors which affect the drone’s performance. Some key sources of vibration are:

- Imbalanced Rotors and Propellers

An uneven distribution of mass in propellers and rotor leads to rotational imbalance and generates oscillations due to high speed.

- Manufacturing Tolerances

Inconsistent motor manufacturing or misaligned motor shafts can introduce mechanical asymmetries, which contribute to the excessive vibration in drone motors.

- Structural Resonance

Every drone frame has a natural frequency. If the motor vibration frequency matches this, resonance occurs, greatly amplifying vibrations.

- Worn Bearings

Over time, motor bearings degrade and produce irregular motion that results in high-frequency vibration and noise.

Understanding the above causes is essential for implementing effective vibration control in drone propulsion systems.

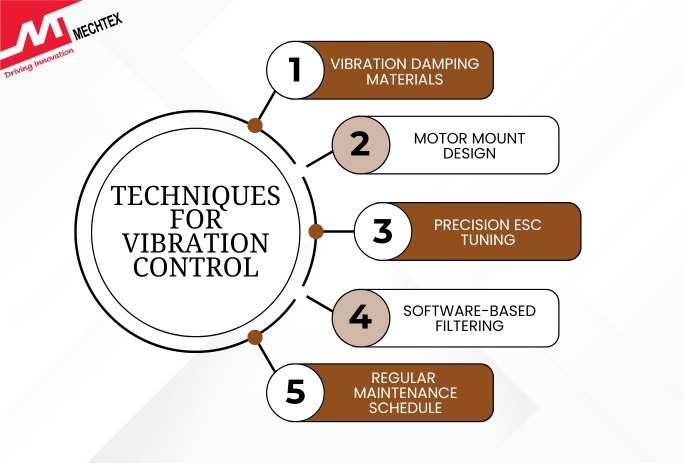

Techniques for Vibration Control in Drone Systems

Several advanced techniques can be implemented for effective vibration control for effective vibration control in drone motors:

- Vibration Damping Materials

Frames made of carbon fibre or composite polymers are preferred for their natural damping properties. Additionally, vibration dampers, rubber mounts, and gel pads are used between:

-

-

-

- Motor and frame

- Flight controller and frame

- Camera gimbals and drone body

- Motor and frame

-

-

These materials absorb and dissipate vibrational energy, preventing it from reaching sensitive electronics.

- Motor Mount Design

Modern drone motor mounts are designed with vibration isolation in mind. Flexible mounts or mounts with built-in damping structure are highly effective in reducing motor-induced oscillation.

- Precision ESC Tuning

Electronic Speed Controllers (ESC) contribute significantly to vibration by introducing irregular current pulses. Advanced ESCs support sine wave commutation and field-oriented Control (ESC), which results in smooth operation.

By precisely tuning ESC parameters like startup torque, ramp-up speed, and throttle curve, one can achieve low-vibration drone motor performance.

- Software-Based Filtering

Flight Controllers implement vibration filtering algorithms, including:

-

-

-

- Low-pass filters (LPF)

- Notch filters

- Kalman filters

-

-

These suppress high-frequency noise from IMU data, making the drone less sensitive to motor-induced vibrations.

- Regular Maintenance Schedule

Dust, humidity, and debris can throw off the motor balance and degrade bearings. A regular maintenance check for friction, shaft misalignment, and propeller wear to ensure long-term vibration control.

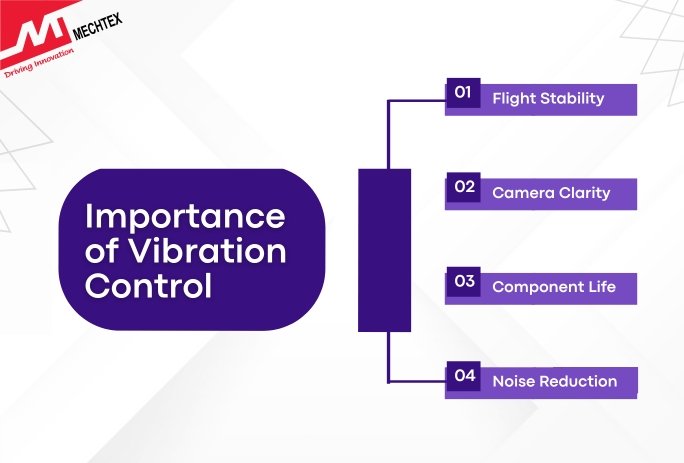

Importance of Vibration Control in Drone Motors

Implementing effective vibration control isn’t just about smooth operation; it is essential for multiple performance dimensions:

- Flight Stability

Vibration disrupts sensors like IMUs (Inertial Measurement Units), causing unstable flight or navigation errors.

- Camera Clarity

In drones used for filming or surveying, uncontrollable vibrations lead to blurred images and jittery videos.

- Component Life

Motors, ESCs, and structural parts wear faster under consistent vibration stress.

- Noise Reduction

Balanced motors contribute to quieter drone operations, critical in defence, wildlife, and urban applications.

Thus, vibration reduction techniques in drone motors are now an industry standard.

Motor Balancing: The First Line of Defence

Balancing drone motors is the most effective method to reduce mechanical vibrations at the source. The goal is to ensure the motor, rotor, and propeller spin around the central axis without deviation.

Dynamic Balancing vs Static Balancing

- Static Balancing

It corrects the weight discrepancies on a stationary motor or propeller assembly.

- Dynamic Balancing

It addresses imbalance during rotation using advanced sensors and software. It is crucial in high-speed drone motors for professional applications.

How to Balance Drone Motors

- Propeller Inspection

Replace chipped or damaged propellers immediately.

- Prop Balancing

Use tape or sanding to fine-tune mass distribution across blades.

- Motor Balancing Gel

Specialised compounds can be applied for minor weight corrections.

- Use of Vibration Analyser Apps

Many professionals rely on smartphone apps connected to IMU logs to analyse vibration levels in real-time.

Balanced motors help in enhancing drone motor performance and extending the lifespan of key components.

Conclusion

Vibration control and balancing in drone motors are crucial for achieving superior flight stability, efficiency, and durability. From simple techniques like propeller balancing to advanced solutions such as dynamic motor balancing and software filtering, these methods help reduce wear, improve data accuracy, and enhance overall drone motor performance.

For drone designers, operators, and manufacturers, investing in low-vibration motor technology and precision tuning isn’t just good engineering—it’s a competitive advantage.