How to Extend the Life of Your Drone Motor

Drone motors are the most important component of any UAV. Drone motors face some issues that significantly impact the performance, flight stability, and overall efficiency of the motor. Understanding their issues and implementing preventative measures ensure optimal performance of the drone motor

Drone motors are the most important component of unmanned aerial vehicles (UAVs). Whether used for aerial photography, surveying, or recreational flying, drones and motors ensure optimal performance and manoeuvrability. Regular maintenance not only extends the lifespan of your drone motor but also enhances overall performance and safety.

In this blog, we will explore the common issues, maintenance tips, and best practices for ensuring drone motors remain efficient for years to come.

Key Components of Drone Motors

Drone motors are critical components that determine the drone’s performance, stability, and efficiency. Here are the key components of drone motors:

- Stator

The stator is the stationary part of the drone motor consisting of multiple copper windings. When windings are energised, they create a magnetic field that interacts with the rotor to drive the drone motor.

- Rotor

It is the moving part of the drone motor. It houses permanent magnets that interact with stator windings to enable rotation.

- Bearings

Bearings ensure smooth and efficient rotor movement by minimising friction. High-quality bearings reduce wear and tear and improve the longevity and performance of the drone motor.

- Electronic Speed Controller (ESC)

It is essential to control the speed and direction of the drone motor. It regulates power delivery to ensure efficient performance.

Also Read

A Comprehensive Guide on Drone Motors| What they are, their types, and their applications

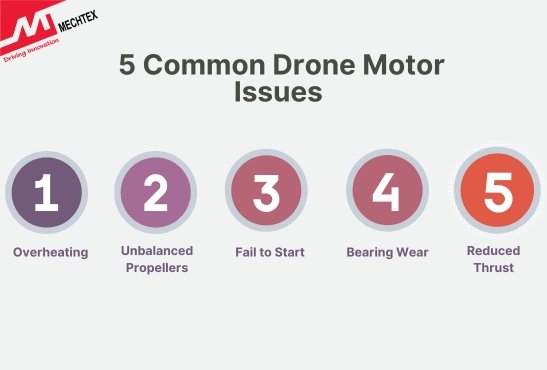

Common Drone Motor Issues

Drone motor issues significantly impact the performance, flight stability, and overall efficiency of the motor. Understanding their causes helps in effective troubleshooting and preventive maintenance. Here are some common issues:

- Overheating

Overheating occurs when the drone motor draws excessive current, often caused by overloading, prolonged high-speed operation and an inadequate cooling system. This can degrade the drone motor’s performance and reduce its lifespan.

- Unbalanced Propellers

Misaligned, damaged, or improperly installed propellers generate uneven forces leading to vibrations and increased drone motor strain. This affects the motor’s thrust efficiency and flight stability.

- Fail to Start

Faulty ESCs, loose or frayed wiring, or damaged motor windings disrupt the drone motor’s commutation process, resulting in irregular stuttering or an inability to start.

- Bearing Wear

Bearings are critical for smooth rotation. Dust, moisture or other environmental factors can cause friction, leading to worn bearings, reduced efficiency and potential motor failure.

- Reduced Thrust

Ageing drone motors, debris build-up inside the motor housing or inconsistent power supply from a battery can diminish thrust affecting lift and flight dynamics.

Addressing the above causes proactively helps extend drone motor life, enhance performance, and maintain smooth drone operations.

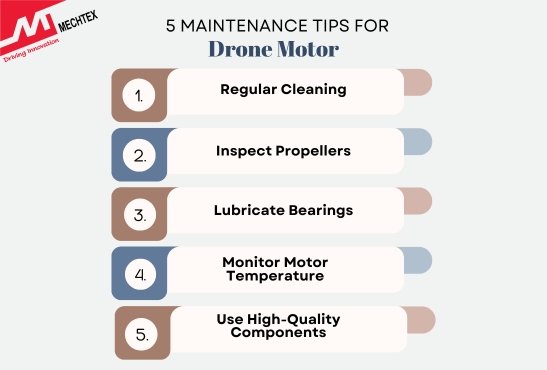

Maintenance Tips for Extending Drone Motor Life

Extending the life of drone motors requires regular maintenance and attention to detail. By implementing proper care and preventative measures, one can ensure optimal performance and longevity of the drone’s motors. Here are some maintenance tips to help:

- Regular Cleaning

Dirt, dust and debris can accumulate in the drone motor and its components, causing friction and wear. Cleaning motors regularly with a soft brush or using compressed air to remove dirt and debris. Avoid using harsh chemicals that can damage the drone motor’s components.

- Inspect Propellers

Check for any cracks, chips or imbalances in the propeller. Damaged or unbalanced propellers place extra stress on the drone motor, which can lead to overheating and premature wear. Replacing the damaged propeller promptly and ensuring they are properly aligned to maintain smooth operation.

- Lubricate Bearings

Proper lubrication of the drone motor bearing helps reduce friction and wear and tear. Apply a light lubricant to the bearings at regular intervals but be careful not to over-lubricate, as excess grease can attract more dirt.

- Monitor Motor Temperature

Overheating is a common cause of drone motor failure. Ensure motors are not overloaded and the cooling system is functioning effectively. Monitor the drone motor’s temperature during flight, especially in high-temperature environments to prevent overheating.

- Use High-Quality Components

Investing in high-quality components and ESCs reduces the likelihood of failure. Quality components are more reliable and efficient and ensure better performance.

Signs It’s Time to Replace a Drone Motor

Replacing a drone motor is essential when it shows signs of wear or damage that can affect performance and safety. Here are key indicators that it’s time to replace a drone motor:

- Excessive Vibration or Noise

If the drone motor begins to emit unusual sounds such as grinding, squeaking, or buzzing, or if it causes excessive vibration, it could indicate internal damage, worn bearings, or misalignment.

- Motor Overheating

While drone motors tend to heat up during prolonged operations, consistent high temperatures or other signs of motor overheating suggest an internal issue, such as damaged windings or poor ventilation.

- Reduced Thrust or Power

If the drone motor fails to produce sufficient thrust, even when the battery is charged and the drone is operating normally it indicates wear or damage to the motor windings or rotor.

- Frequent ESC Errors

If the drone motor is frequently throwing errors or losing ESC connection despite troubleshooting of ESC, it indicates a deeper issue with the motor itself that requires replacement.

Conclusion

Drone motor maintenance is not just about prolonging the life of the motors; it’s about ensuring the drone performs optimally and safely every time it takes to the skies.

By adopting a proactive maintenance routine, one can save costs, avoid unexpected failures, and maximise the performance of the UAV. Remember, the care we invest in our drone motors today will pay off in terms of reliability and performance for years to come.