Understanding Linear Encoders - Intoduction, Working and Application

A linear encoder is a measuring device that detects linear movement or position of an object. It detects the position or movement of an object along a straight path and converts that information into an electrical signal for precise measurement.

In the realm of industrial automation, robotics, and high-precision positioning systems, accuracy and feedback are essential. This is where the linear encoder comes into play. These sophisticated devices serve as a backbone for the motion control system by delivering real-time feedback with precision.

In this blog, we will delve into what linear encoders are, how they work, their types and their applications.

What is a Linear Encoder?

A linear encoder is a sensor, transducer, or measuring device that detects linear movement or position along a single axis and converts it into electrical signals. It is used in applications requiring high precision and accuracy, such as CNC machines, coordinate measuring machines, semiconductor equipment and robotic systems.

Unlike rotary encoder that measures angular motion, linear encoder measures straight-line displacement. They consist of two main components: the scale and the readhead (sensors). The scale is fixed and contains positional reference, and the readhead (sensors) moves along the scale and interprets the positional data.

Linear encoders can be absolute or incremental. Absolute encoders provide a unique position value for every point along the scale, which enables instant position referencing on power up. In contrast, incremental encoders measure changes in position from a reference point and require a homing for start-up.

Watch the YouTube Video by "NeedToDIY" about linear encoders and their use in printing.

Linear encoders are essential for systems where accurate position feedback, repeatability, and tight tolerances are required. Their non-contact version offers advantages such as no mechanical wear, long life, and low maintenance requirements.

Moreover, they help reduce system errors caused by thermal expansion, mechanical backlash, or lead screw inaccuracies by providing direct position feedback.

Working Principle of Linear Encoder

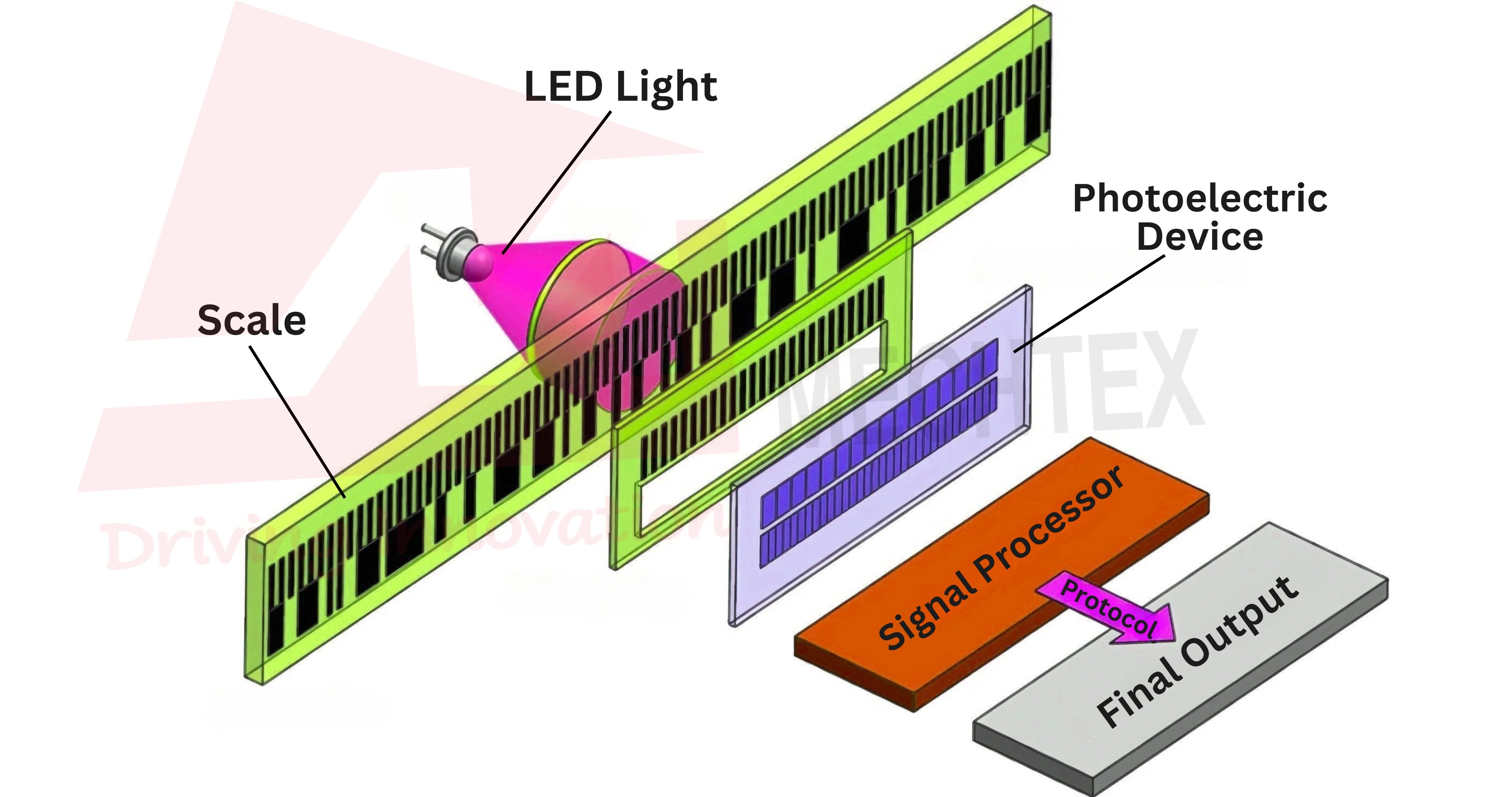

A linear encoder works by detecting the position or movement of an object along a straight path and converts that information into an electrical signal for precise measurement. It consists of two main components: scale and readhead (sensor).

The scale is fixed along the path of motion and contains repeating physical patterns such as lines, magnetic poles or markers depending upon the technology used. The readhead is attached to the moving part of the machine and moves along the scale. As it moves, it continuously reads the scale patterns and generates signals that correspond to the position.

When motion occurs, the readhead detects changes in the scale pattern. These changes are translated into electrical pulses or signals. The number of pulses, their frequency or their specific code is processed by control systems such as CNC controllers or PLCs to determine the precise linear position, speed, or direction of the object.

The key to the linear encoder’s function lies in the relative movement between the scale and readhead. This motion allows the encoder to continuously monitor and provide the exact location of the object along its linear path.

Types of Linear Encoder

Linear encoders are categorised based on the sensing technology they use and the type of output signal they generate. Below are the main types of linear encoders:

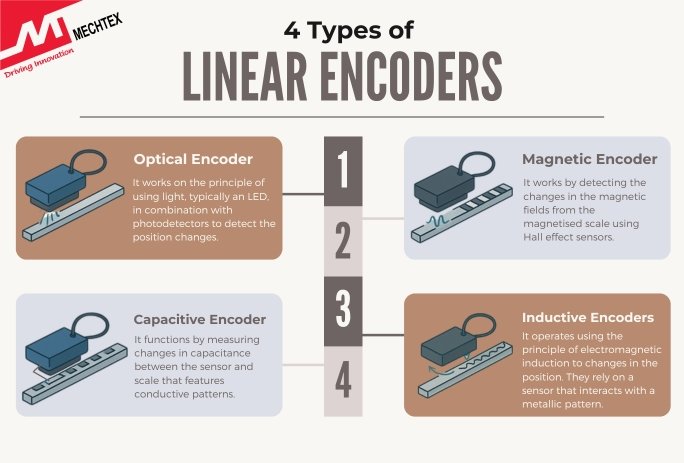

- Optical Linear Encoder

It works on the principle of using light, typically an LED, in combination with photodetectors to detect the position changes. Optical encoders are commonly used in CNC machines and semiconductor manufacturing equipment.

- Magnetic Linear Encoder

It works by detecting the changes in the magnetic fields from the magnetised scale using Hall effect sensors. As the sensor moves along the scale, it reads these magnetic variations to determine position.

These encoders are well-suited for industrial automation, packaging machines, and other applications in harsh environments.

- Capacitive Linear Encoder

It functions by measuring changes in capacitance between the sensor and scale that features conductive patterns. These encoders are typically used in lower-precision machinery and budget-sensitive applications.

- Inductive Linear Encoders

It operates using the principle of electromagnetic induction to detect changes in the position. They rely on a sensor that interacts with a metallic pattern embedded on the scale.

As the sensor moves, it experiences variations in inductance, which are translated into position data. These encoders are particularly suited for industrial equipment operating in harsh environments, where durability and reliability are crucial.

Applications of Linear Encoder

Linear encoders are integral to many modern systems that demand precision and repeatability. Common applications include:

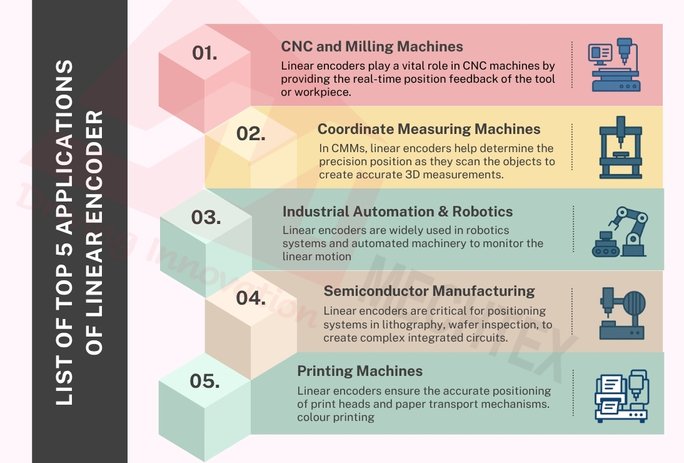

- CNC Machines

Linear encoders play a vital role in CNC machines by providing real-time position feedback of the tool or workpiece. This ensures highly accurate cutting, shaping and drilling.

These encoders continuously monitor linear movements, allowing the controller to adjust tool paths precisely.

- Coordinate Measuring Machines (CMMs)

In CMMs, linear encoders help determine the precise position as they scan the objects. This data is used to create accurate 3D measurements of components for quality control and reverse engineering.

Linear encoders are widely used in robotics systems and automated machinery to monitor linear motion. They enable precise and repeatable movement control, essential for tasks such as pick-and-place, packaging, and assembly.

- Semiconductor Manufacturing Equipment

Semiconductor fabrications require submicron precision, and linear encoders are critical for positioning systems in lithography, wafer inspection, and deposition equipment. It enables precise alignment and movements, which are necessary for creating complex integrated circuits.

- Printing Machines

In high-speed printing systems, linear encoders ensure the accurate positioning of print heads and paper transport mechanisms. This is crucial for maintaining alignment, especially in colour printing, where slight positional errors can lead to blurred or misregistered images.

Conclusion

Linear encoders are indispensable components in modern automation and motion control systems. They deliver precise, real-time feedback necessary for high-speed and high-accuracy operations. With a variety of types tailored to different environments and performance needs, linear encoders empower industries to innovate and maintain tight tolerances in their manufacturing and inspection processes.

Whether you are designing a CNC machine or an industrial robot, understanding the concept of linear encoders can help you make informed decisions that impact system performance and reliability.