The Science of Drone Motor and Propeller Combinations

A propeller is a device used to generate thrust for lift and manoeuvrability in drones. Choosing the right propeller-motor combinations involves evaluating multiple parameters to maximise the efficiency, flight time, and thrust of a drone.

In the world of drones, the synergy between drone motors and propellers is pivotal to achieving optimal performance. The right motor and propeller combination can enhance thrust, reduce power consumption and improve overall efficiency. Understanding the dynamics of this relationship requires a deep dive into aerodynamics, motor specifications and the physics of propulsion.

What is Propeller?

A propeller is a device used to generate thrust by converting rotational motion into linear force. It consists of blades arranged around a central hub with each blade designed like an airfoil to maximise aerodynamic efficiency. When a propeller spins, the blade pushes against the surrounding air or water creating pressure. This results in thrust, propelling an object like an aircraft or drone.

Watch the YouTube Video by "Motion RC" to learn about propellers.

Propellers are critical for lift and manoeuvrability in drones. They come in various sizes, pitches, and materials, influencing drone performance. A propeller's design significantly impacts drone stability, speed, and load-carrying capability. For instance, lightweight materials such as carbon fibre reduce the drone motors workload. The choice of propeller depends on the drone's application, whether it’s racing, aerial photography, or delivery.

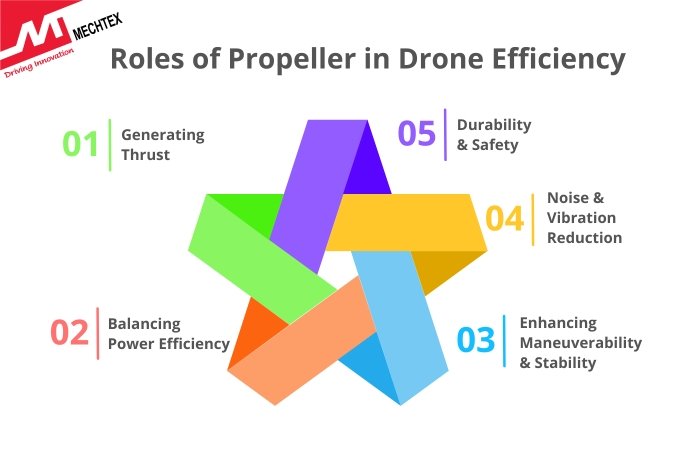

Role of Propellers in Drone Efficiency

Propellers are a critical component of drones, significantly impacting their efficiency, stability, and overall flight capabilities. By converting the rotational motion of the motor into thrust, propellers enable the drone to lift off, manoeuvre, and maintain stability in the air.

Here's a deeper look at the role of propeller in drone:

- Generating Thrust: Propellers are designed to push the air downward creating an equal and opposite reaction force that lifts the drone upwards. The amount of thrust generated depends upon:

-

-

-

- Size: A large propeller produces more thrust but may require more power from the drone motor.

- Pitch: A higher pitch moves more air with each rotation increasing thrust and energy consumption.

- Blade Count: Fewer blades are more efficient, while more blades provide smooth flight and better control.

-

-

- Balancing Power Efficiency: An efficient propeller design minimises energy loss and maximises flight time affecting the drone's efficiency. Factors affecting efficiency include:

-

-

-

- Material: Lightweight materials like carbon fibre reduce energy consumption.

- Aerodynamics: A well-designed blade profile reduces drag and enhances the lift.

- Motor Compatibility: Matching the propeller with the drone motor ensures optimal performance without overloading.

-

-

- Enhancing Maneuverability and Stability

Propellers directly influence the drone’s ability to hover, turn, and maintain balance. The configuration of propellers in quadcopter or hexacopter distributes thrust and torque for precise control.

- Noise and Vibration Reduction

The design of the propeller can impact the noise and vibration generated during flight. Larger, slower-spinning propellers tend to be quieter, which is essential for drones used in applications like filming, surveillance, or medical delivery.

- Durability and Safety

Propellers must withstand high rotational speeds and occasional impacts. Using durable materials and proper guards reduces the risk of damage and ensures the safety of operators and bystanders.

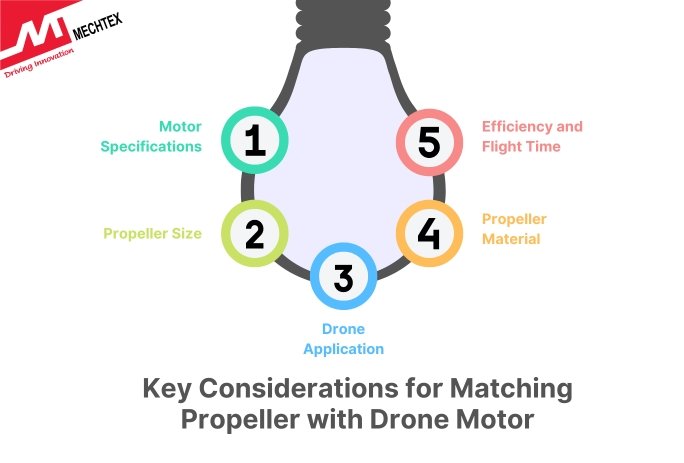

Matching Propeller with Drone Motor: Key Considerations

Choosing the right propeller for your drone motor is critical for optimising performance, flight and stability. Here are the key considerations for matching a propeller with a drone motor:

- Motor Specifications

- KV Rating: A drone motor with a high KV rating spins faster and works best with a smaller, lighter propeller. A low-KV drone motor is slower but has higher torque and is suitable for large propellers.

- Torque: Ensure the drone motor has sufficient torque to handle the load to the propeller without stalling.

- Power Output: Match the drone motor's maximum power with the expected load from the propeller to avoid overloading.

- Propeller Size

- Diameter: A propeller with a large diameter creates more lift but requires more torque making it suitable for low KV drone motors. Smaller diameters are lighter and better for high-KV motors.

- Pitch: The pitch determines the distance the propeller moves in one rotation. A higher pitch increases speed but demands more power.

- Drone Purpose

Small and high-pitch propellers provide high speed and agility and are suitable for racing drones. However, large, lower-pitch propellers provide easy lift and high load-carrying capacity and are suitable for cinematic drones or heavy-lift drones.

- Propeller Material

Lightweight and affordable propellers are suitable for small drones. Lightweight but strong propellers are suitable for high-performance drones.

- Efficiency and Flight Time

Ensure the propeller and drone motor combination delivers optimal thrust without excessively draining the battery. Also, test different configurations to balance the thrust and energy efficiency of the drone motor.

Calculating Optimal Propeller-Motor Combinations

Calculating optimal propeller-motor combinations involves evaluating multiple parameters to maximise efficiency, flight time, and thrust. Here's a structured approach:

- Propeller Testing

Using thrust enables precise testing of propeller-motor combination, measuring thrust, and efficiency. This hands-on approach helps in determining the optimal setup for specific drone applications and validates theoretical calculations with real-world performance metrics.

- Efficiency Maps

Efficiency maps provided by the manufacturer graphically illustrate drone motor and propeller performance across varying loads and speeds. These maps simplify the selection process enabling engineers to identify combinations that maximise efficiency and meet specific requirements.

- Simulation Tools

Simulation tools like eCalc and OpenProp enable virtual testing of motor-propeller combinations. These tools help to evaluate thrust, power consumption and flight endurance before physical testing significantly reducing development time and associated costs.

- Weight Balancing

Poor weight distribution across drones ensures propeller thrust is efficiently utilised. Testing motor-propeller combinations with different payloads helps optimise stability, endurance, and responsiveness ensuring drone performance efficiently under varying conditions.

Case Study: Optimising for Different Applications

- Racing Drones

Racing drones prioritise speed and agility. High KV drone motors paired with small, high-pitch propellers offer quick acceleration and rapid directional changes.

- Cinematography Drones

For aerial filming, stability and smooth movement are necessary. Low KV drone motors with large multi-blade propellers provide the necessary stability and lift at slow speed.

- Surveying and Mapping Drones

Drones used in surveillance and mapping need endurance and precision. Medium KV drone motors with efficient, two-blade propellers strike a balance between flight time and performance.

Conclusion

The science of motor-propeller combinations is both intricate and rewarding. By understanding the principles of thrust, torque, and aerodynamics, drone enthusiasts, professionals or engineers can design systems tailored to specific applications. Experimentation, backed by data and simulation, ensures optimal efficiency, making the drone more reliable and capable of achieving its intended purpose.