Space Vector Modulation (SVM) in BLDC Motor Control

Space vector modulation (SVM) is a sophisticated technique used in the control of AC and DC motors. It is a form of Pulse Width Modulation (PWM) that provides efficient, smooth and precise motor control by generating a rotating magnetic vector.

BLDC motors have become the standard solution for applications demanding high efficiency, low maintenance, and precise control. From electric vehicles to drones and industrial automation systems, these motors are used everywhere.

However, the magic behind their smooth operation lies in advanced control techniques such as space vector modulation (SVM). In this blog, we will explore what space vector modulation is, how it works, and why it is superior to traditional modulation methods.

What is Space Vector Modulation (SVM)?

Space vector modulation (SVM) is a sophisticated technique used in the control of AC and DC motors, particularly inverters driving three-phase motors such as BLDC motors and induction motors. It is a form of Pulse Width Modulation (PWM) that provides efficient, smooth and precise motor control by generating a rotating magnetic vector.

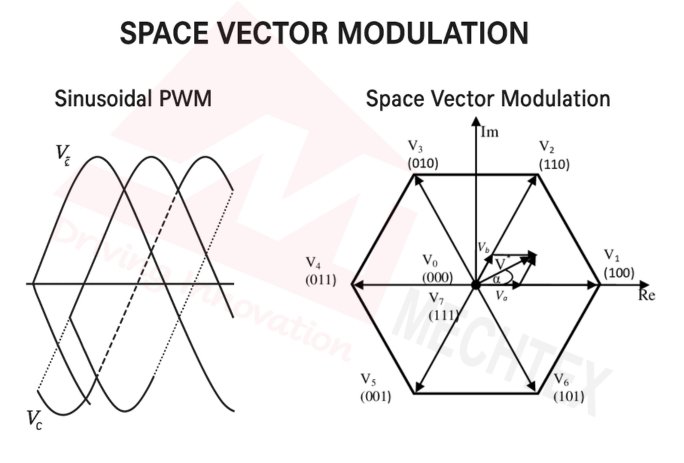

Unlike the traditional sinusoidal PWM technique, which modulates each phase independently, SVM considers the three-phase system as a whole and treats the output voltage as a vector in a two-dimensional plane. This vector-based approach allows for better utilisation of the DC bus voltage, typically achieving up to 15% higher voltage output compared to sinusoidal PWM.

The primary advantages of space vector modulation (SVM) include reduced switching losses, better voltage control, smooth motor operation and higher efficiency. It is widely adopted in applications requiring precise speed and torque control, such as industrial automation, robotics, electric vehicles, and advanced motor drives.

Working of Space Vector Modulation (SVM) Technique

Space Vector Modulation (SVM) is a sophisticated Pulse-Width Modulation (PWM) technique used for controlling three-phase inverters, primarily in applications like motor drivers. It converts a set of three-phase sinusoidal voltage references into a sequence of switching states of the inverter.

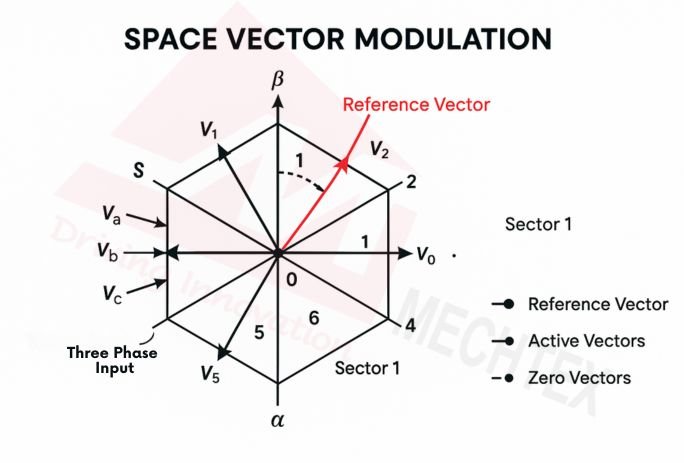

The core principle of SVM is to represent the three-phase voltages as a single rotating vector in a two-dimensional α-β coordinate system. The three-phase input is transformed into a space vector, which rotates in the hexagonal pattern formed by the inverter’s six active voltage vectors and two zero vectors.

At any instant, the desired output voltage vector is approximated by time-weighted averaging of the two adjacent vectors and the zero vector within a specific 60° sector. These vectors are selected so that the resultant vector closely mimics the reference vector over one switching cycle.

SVM enhances DC bus utilisation, minimises harmonic distortion and provides smooth voltage waveforms, which improve motor performance and reduce losses. By systematically sequencing the inverters switches, it ensures precise control of amplitude and frequency, making it ideal for variable frequency drives (VFDs) and field-oriented control (FOC) in motors.

Applications of Space Vector Modulation (SVM) Technique

Space Vector Modulation (SVM)-controlled BLDC motors offer superior performance in terms of torque ripple minimisation, efficient DC bus voltage utilisation, and smoother control compared to conventional PWM techniques. This makes them suitable for high-performance, dynamic, and energy-efficient applications. Below are key application areas:

- Electric Vehicles (EVs)

SVM-controlled BLDC motors provide precise torque and speed regulations crucial for EVs. This enables smooth acceleration, efficient regenerative braking, improved energy utilisation for extended driving ranges, and reduced power losses.

In robotics and CNC machines, the SVM technique offers smooth and rapid motor control, enabling high precision positioning. Its efficient DC bus utilisation reduces heat generation and increases the lifespan of the motor.

Variable speed control through SVM ensures quiet, efficient operation of compressors and fans. It adjusts its motor speed based on demand, reducing energy consumption and enhancing thermal comfort.

- Home Appliances

SVM in appliances like washing machines and refrigerators delivers smooth, quiet, and energy-efficient motor control. It ensures stable speed regulation under varying loads, enhancing user experience and motor reliability.

Conclusion

Space Vector Modulation is a game-changer in BLDC motor control. It replaces traditional switching techniques with an elegant and mathematically robust algorithm that enhances efficiency, reduces noise, and delivers smoother torque. When paired with Field-Oriented Control, SVM unlocks the full potential of BLDC motors, making them suitable for high-performance and mission-critical applications.

As industries continue to demand smarter and cleaner motor control strategies, SVM stands out as a leading solution that combines theory and engineering into real-world benefits.