Slotless BLDC Motors vs. Slotted BLDC Motors

Slotless BLDC motor is a BLDC motor without slots to ensure smooth operation under varying load conditions. The Slotted BLDC motor is a BLDC motor characterised by the slots to generate high torque and high power density.

Brushless motors have become the ideal solution for many industries including robotics, automotive, and consumer electronics due to their efficiency, durability, and superior performance. Among the many designs of BLDC motors, slotted and slotless BLDC motors stand out as two popular choices each with unique characteristics suited for different applications.

In this blog, we will explore fundamental differences between slotless and slotted BLDC motors, comparing their construction, performance, advantages, and limitations to help engineers make informed decisions.

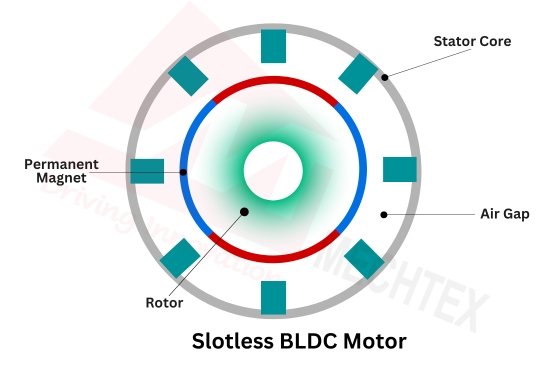

What is a Slotless BLDC Motor?

A slotless BLDC motor is a brushless DC motor designed without slots providing a unique configuration that impacts its magnetic and performance characteristics.

Unlike traditional BLDC motors with slotted cores, the slotless design provides a uniform gap between the rotor and stator to ensure smooth operation. It leads to consistent torque and better performance under varying load conditions.

One significant characteristic of slotless BLDC motors is their ability to achieve high rotational speed which enables efficient operation in high-speed applications. Additionally, the slotless design allows for lightweight construction, making slotless BLDC motors suitable for industries requiring compact and low-inertia motors.

These characteristics make spotless BLDC motors an appealing choice for industries prioritising smooth operation, high-speed capability, and reliability.

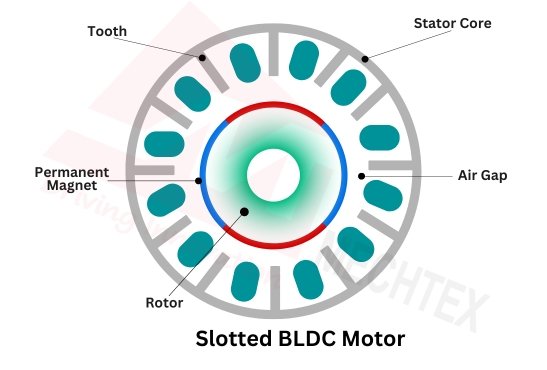

What is a Slotted BLDC Motor?

A slotted BLDC motor is a brushless DC motor characterised by the presence of stator slots which play a critical role in magnetic behaviour and overall performance of the motor.

The slotted design establishes distinct magnetic paths to enable a strong interaction between the rotor and stator. This results in high torque generation and high power density, making the slotted BLDC motor well-suited for applications requiring robust torque performance at varying speeds.

One of the defining characteristics of slotted BLDC motors is their ability to provide precise control over speed and torque. It is essential in environments where consistent and responsive motor behaviour is critical.

Slotted BLDC motors also maintain a balance between cost and performance due to their efficient use of standard manufacturing processes and materials. This makes them versatile to operate in diverse conditions while delivering reliable performance.

Slotless BLDC Motor vs Slotted BLDC Motor

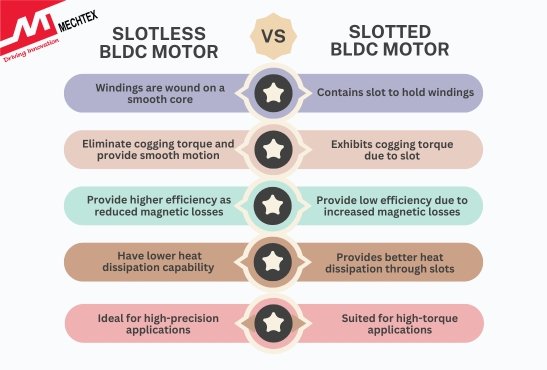

Here are the key differences between slotless and slotted BLDC motors:

- Stator Design

Slotless BLDC Motor: Windings are wound on a smooth core, eliminating slots and minimising magnetic interaction.

Slotted BLDC Motor: Contains slot to hold windings, ensuring robust mechanical stability and magnetic interaction.

- Cogging Torque

Slotless BLDC Motor: Eliminating cogging torque and providing smooth motion and enhanced operation.

Slotted BLDC Motor: Exhibits cogging torque due to slot and magnetic field interactions causing uneven motions.

- Efficiency

Slotless BLDC Motor: Provide higher efficiency as reduced magnetic losses enhance energy conversion and performance.

Slotted BLDC Motor: Provide low efficiency due to increased magnetic losses caused by slot-induced flux disturbances.

- Thermal Management

Slotless BLDC Motor: Lower heat dissipation capability, requiring additional thermal management systems.

Slotted BLDC Motor: Provides better heat dissipation through enhanced airflow and slot geometry.

- Applications

Slotless BLDC Motor: Ideal for high-precision applications like medical devices, drones, and aerospace systems.

Slotted BLDC Motor: Suited for high-torque applications like electric vehicles, robotics, and heavy machinery.

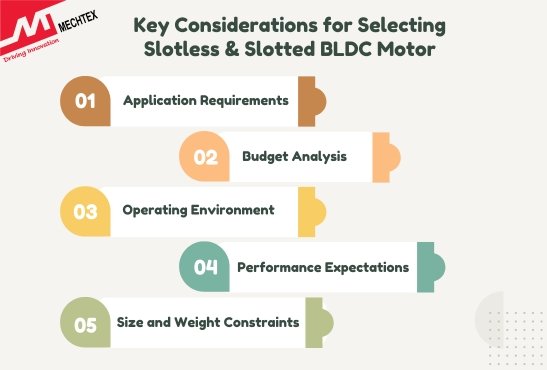

Key Considerations for Selecting Slotless and Slotted BLDC Motor

When choosing between slotted and slotless BLDC motors, consider the following factors:

- Application Requirements

Identify your application requirements as slotted BLDC motors excel in torque while slotless BLDC motors ensure smooth operation ideal for sensitive equipment like medical devices or robotics.

- Budget

Assess upfront costs and operational expenses. Slotted BLDC motors are cost-effective, whereas slotless BLDC motors may require higher investment but reduce long-term maintenance due to minimal cogging.

- Operating Environment

Slotless BLDC motors operate quieter and cooler making them ideal for noise-sensitive environments, while slotted motors suit rugged, high-torque applications.

- Performance Expectations

Analyse required speed-torque characteristics of applications. Slotted BLDC motors deliver high torque at low speeds, while slotless BLDC motors provide consistent torque at high speeds, which is suitable for applications demanding precision motion.

- Size and Weight Constraints

Slotless BLDC motors are generally lighter and more compact, making them suitable for space-constrained designs, while slotted BLDC motors offer a more robust structure for heavy-duty operations.

Conclusion

Both slotted and slotless BLDC motors have their distinct advantages and limitations, making them suitable for different use cases. While slotted BLDC motors shine in high-torque and cost-sensitive applications, slotless BLDC motors excel in precision-driven, noise-sensitive environments. Understanding the specific requirements of your application is crucial to selecting the most suitable motor.

By evaluating factors like torque, efficiency, noise, and cost, engineers can make an informed choice between these two motor types, ensuring optimal performance and reliability in their designs. As industries continue to demand more from BLDC motors, innovations in both slotted and slotless designs will undoubtedly push the boundaries of what these motors can achieve.