Thermal Management in BLDC Motors

Thermal management is critical for optimising performance, extending lifespan, and ensuring the efficiency of BLDC motors in various industrial applications. It involves both design and operational strategies to minimise heat generation and enhance heat dissipation.

BLDC motors are widely used in various industrial applications due to their efficiency, reliability and compact design. However, like other electric motors, BLDC motors generate heat during operation. Managing this heat effectively is critical to maintain its performance, efficiency and lifespan. In this blog, we will delve into the significance of thermal management in BLDC motors, the sources of heat, and strategies to mitigate thermal issues.

What is BLDC Motor?

BLDC motors are advanced electric motors that use electronic commutation instead of mechanical brushes and commutators for operation. They operate based on the interaction between the stator’s magnetic field and rotor’s permanent magnet. The absence of brushes and commutators makes BLDC motors highly reliable with low maintenance requirements.

The construction of BLDC motors includes a rotor with permanent magnets, a stator with wound coils, and an ESC (electronic speed controller) to regulate the speed and power of the motors.

Watch the YouTube Video by "The Engineering Mindset" to learn about the working of BLDC motors.

These motors can be categorised into two types: outrunner BLDC motors and inrunner BLDC motors. In outrunner BLDC motors, the rotor surrounds the stator, while in an inrunner BLDC motor, the rotor is inside the stator. Each type of BLDC motor is suitable for specific applications based on torque and speed needs.

BLDC motors are known for their high power density, efficiency, and precise control, which makes them ideal for applications such as drones, robotics, electric vehicles, and industrial automation.

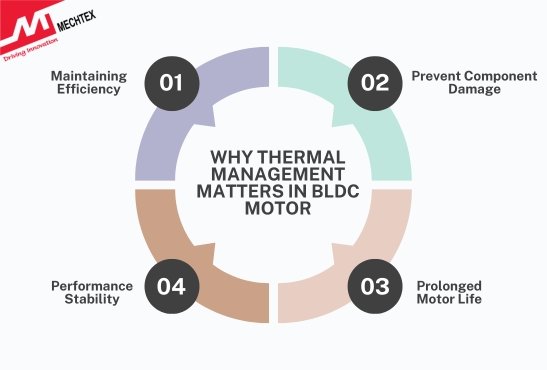

Why Thermal Management Matters in BLDC Motor

Thermal management in BLDC motors is critical for optimising performance, extending lifespan, and ensuring efficiency in various industrial applications. Here are some key reasons for maintaining thermal management in BLDC motors:

- Maintaining Efficiency

Overheating increases resistance in windings reduces efficiency and causes high power consumption. Proper thermal management ensures BLDC motors operate within optimal temperature ranges.

- Prevent Component Damage

Excessive heat degrades insulation materials, magnets, and electronic components leading to permanent damage. This risk is particularly high in high-performance applications such as drones, robotics, and electric vehicles.

- Prolonged Motor Life

Thermal stress leads to frequent wear and tear. Using effective cooling mechanisms such as heatsinks, forced air cooling, or liquid cooling, significantly enhances the BLDC motors operational life.

- Performance Stability

Temperature fluctuations affect the torque and speed characteristics of the BLDC motor and reduce precision in critical applications like CNC machines and medical devices.

Sources of Heat Generation in BLDC Motors

In BLDC motors, heat generation is inevitable due to electrical and mechanical processes. Understanding the source of heat generation in BLDC motors is crucial for effective thermal management and optimising performance. Below are some primary sources of heat generation in BLDC motors:

- Copper Losses

Copper losses occur due to electrical resistance in stator windings, which converts a portion of electrical current into heat. This loss is particularly significant under high current loads and affects the life of BLDC motors. To mitigate these copper losses, high-quality copper wires and optimised windings are essential to reduce resistance and improve efficiency.

- Iron Losses

It results from alternating magnetic fields in the stator core which cause hysteresis and eddy current. This heat dissipation becomes more crucial at high operating frequencies. Laminated core and low-loss magnetic materials are commonly used to reduce iron losses and enhance the overall efficiency of BLDC motors.

- Magnetic Losses

It occurs when the rotor’s permanent magnets are exposed to high temperatures which lead to partial demagnetisation and inefficient energy conversion. This inefficiency increases the heat in the BLDC motor. Using high-grade magnets minimises the magnetic losses and ensures stable performance under demanding conditions.

- Frictional Losses

It arise from the interaction between moving parts of BLDC motors such as bearings and other components. This friction generates heat which affects the BLDC motor's stability and operational life. Using high-quality bearings and proper lubrication is critical in minimising frictional losses and ensuring smooth operation.

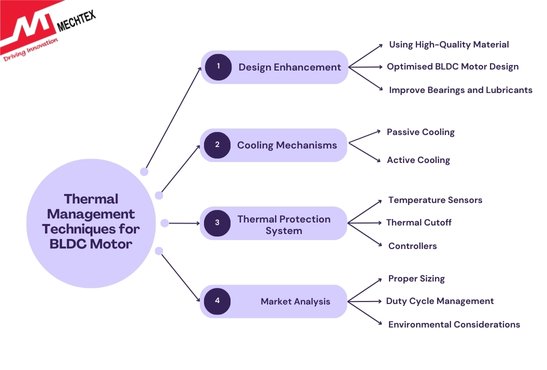

Thermal Management Techniques for BLDC Motor

Thermal management in BLDC motors involves both design and operational strategies to minimise heat generation and enhance heat dissipation. Key thermal management techniques for BLDC motors include:

Design Enhancement

- Using High-Quality Material

Use low-resistance copper windings to reduce copper losses and use laminated core to reduce eddy current.

- Optimised BLDC Motor Design

Slot and winding designs are used to optimise the airflow and reduce heat generation. Using advanced rotor design reduces friction losses.

- Improve Bearings and Lubricants

Using high-quality bearings reduces frictional losses. Using heat-resistant lubricants ensures efficient performance under high temperatures.

Cooling Mechanisms

- Passive Cooling

The passive cooling technique relies on natural convection where heat is dissipated through the BLDC motor’s housing. Proper housing enhances the passive cooling technique by increasing the surface area and improving heat transfer efficiency.

- Active Cooling

Forced air cooling utilises fans or blowers to increase airflow around the BLDC motor to reduce the surface temperature.

On the other hand, liquid cooling involves circulating a liquid medium to absorb and remove heat from the BLDC motor. This approach is significantly more efficient than air cooling, making it ideal for high-power applications.

Thermal Protection System

- Temperature Sensors

It includes sensors which monitor the winding and housing of the BLDC motor to enable timely interventions for proper heat dissipation.

- Thermal Cutoff

The automatic cutoff mechanism protects the BLDC motor from overheating.

- Controllers

Controllers adjust the speed of the BLDC motor to manage temperature dynamically.

Operational Strategies

- Proper Sizing

Select a BLDC motor with adequate power capacity to avoid overloading and excessive heating.

- Duty Cycle Management

Avoid continuous operation under high load to avoid heat generation.

- Environmental Considerations

Ensure adequate ventilation and avoid placing the motor in high-temperature environments.

Conclusion

Thermal management is crucial for the efficient and reliable operation of BLDC motors. By addressing heat generation through design enhancements, cooling mechanisms, and operational strategies, various industries significantly improve motor performance and lifespan. As technologies evolve, the future of thermal management promises even greater efficiency and innovation, ensuring that BLDC motors remain a cornerstone of modern engineering solutions.