Basics of Permanent Magnet Stepper Motor- What they are, their components, and their applications

A permanent magnet (PM) stepper motor is an electrical motor which uses permanent magnets to create the rotating magnetic field. When the magnetic field is generated, and interacts with the rotor to create rotational movements.

“Permanent magnet stepper motors, with their precise control and reliability, turn digital commands into graceful mechanical motion of application”

Have you ever wondered how Industrial machines, robotic arms, and other devices move with such precision and accuracy? The answer lies in the power of permanent magnet stepper motors. These small but mighty motors are essential components in a wide range of industries and applications, from CNC machines and 3D printers to medical equipment and consumer electronics.

In this blog, we will provide you with a comprehensive understanding of permanent magnet stepper motors including their introduction, their structure, and their role in various industries and applications.

What is a Permanent Magnet Stepper Motor

A permanent magnet (PM) stepper motor, is a electrical motor widely used for precise control in applications. Unlike other stepper motors, depends upon the electromagnets in the stator to generate the magnetic field. The Permanent stepper motor uses its permanent magnet to create this magnetic field. This design excludes the need for a separate excitation source, simplifies its construction, and improves reliability.

The working principle of the PM stepper motor is the interaction between the magnetic field of the rotor and stator. The rotor consists of a permanent magnet. When the magnetic field generated by the stator interacts with the permanent magnet of the rotor, the rotor experiences a torque and helps in rotational movement. By controlling the flow of current in stators winding, we can control the movement of the PM Stepper motor.

Please find a visual representation of what is a PM stepper motor and how it works from the YouTube video presented by "RealPars"

Permanent magnet stepper motors offer various advantages such as high efficiency, low power consumption, precise positioning, high reliability, and many more. This advantage makes PM stepper motors an ideal solution for various applications such as robotics, automation, CNC machines, and 3D printers that require accurate motion control in their operations.

Also Read

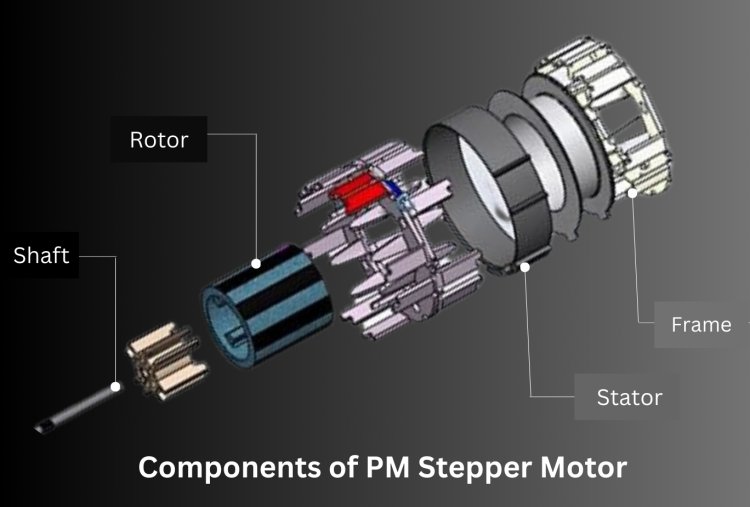

Components of a Permanent Magnet Stepper Motor

A permanent magnet (PM) stepper motor is a type of stepper motor that utilises permanent magnets to create the magnetic field necessary for operation. It consists of various components such as stator, rotor, shaft, and windings. These components are working together to improve the reliability of these motors.

The important components of permanent magnet stepper motors are:

-

Stator

It is the stationary part of the motor. It surrounds the rotor and converts the electrical energy into mechanical energy. It consists of a series of electro-magnets in a circular pattern and is placed evenly around the circumference of the motor.

These electro-magnets are made up of coils of wire surrounding the core material of the stator. These stator coils are energized in a specific pattern, to determine the direction and speed of the motor.

The design of the stator varies with the type of stepper motor. In a hybrid stepper motor, a stator consists of both a permanent magnet and electromagnet, while in a reluctance stepper motor and PM stepper motor it only consists of electromagnets. However, the basic principle of the stator to create a magnetic field remains the same.

When an electric current passes to the stator, it creates a magnetic field. This magnetic field interacts with the permanent magnet of the rotor and causes the rotor to rotate in a specific direction.

The stator also plays a crucial role in controlling the speed of the PM stepper motor. Changing the frequency and amplitude of the current applied to the stator constantly helps to adjust and control the speed of the motor.

-

Rotor

The rotor is the moving part of the motor. It is made up of permanent magnets arranged in specific patterns to interact with the magnetic field produced by the stator to rotate the motor. When an electric current passes through the stator, it creates a magnetic field. This magnetic field interacts with the permanent magnet of the rotor and causes the rotor to move. By controlling the timing and sequences of the stator’s magnetic field, the rotor can move in small steps in a precise manner.

A rotor also consists of teeth or grooves to improve the performance of the motor. The teeth on the rotor provide more surface area to the magnetic field of the stator to interact with the rotor and help to increase the torque of the motor. These teeth also help to reduce the cogging effect in 3-phase stepper motors.

-

Shaft

The shaft is an important component of the permanent magnet stepper motor. It is a cylindrical rod connected to the rotor of the motor. Its main function is to transfer the rotational movement of the motor to the external device with the help of electrical signals.

It is made up of high-quality materials such as steel, aluminium, or stainless steel to withstand high torque and extreme pressure conditions. It is supported with bearings at each end. These bearings decrease friction in the motor and allow the shaft to rotate freely without any interruption.

The key characteristic of a shaft is to provide precision in movement. It must be precisely attached to an external device for smooth and precise movement. Any imperfection in the attachment may cause the motor to vibrate and create uneven movements. This characteristic is useful for many applications such as robotic arms, CNC machines, 3D printers, etc.

-

Controller

The controller is an integral part of the Permanent magnet stepper motor. It is responsible for the accurate movement of the motor. The external devices such as computers or microprocessors send commands to controllers. These commands then convert into electrical signals and control the current supplied to the winding of the motor.

This device works on pulse width modulation(PWM) technique to control the current and voltage supplied to the windings. This technique involves the on and off of the power supply at high frequency to control the current and voltage supplied to the winding of the motor. This technique allows precise positioning and accurate movement of the motor.

This device also works on micro-stepping techniques. In this technique, the external device sends commands to the controller to regulate the flow of current in the motor’s winding to cause the rotor to move at a specific angle with micro steps. This technique helps for smooth and precise movements and torque control of the motor.

It also includes a protection mechanism to protect the motor from excessive current supply, overheating, or prevent the motor from drawing too much current from the motor.

Other Components

-

Bearing

It is an essential component of the PM stepper motor. They provide support to the rotor and shaft to allow the motor to rotate smoothly. They are generally made up of high-quality materials such as metal balls or rollers to reduce the friction and wear and tear of the motor to ensure a long life span of the motor.

-

Windings

Windings are the coils of wire wound around the poles of the stator. When current is passed through these windings, it creates a magnetic field to interact with the rotor. The supply of current to this winding is controlled by the controller to ensure the precise control and accurate movement of the motor.

Applications of Permanent Magnet Stepper Motors

Permanent magnet stepper motors offer precision, reliability, and versatility. This makes them a vital part of various industries and their applications.

Here are some common applications of PM stepper motors:

-

CNC Machines

CNC machines are highly advanced machines used for cutting, drilling, and shaping various types of materials. Permanent magnet stepper motor plays a crucial role in the operations of CNC machines.

Permanent magnet stepper motors move in small steps with high step resolution which results in precise positioning and allows to cutting of the materials in specific designs and shapes. These machines drill holes in materials with precision and repeatability. PM stepper motors offer high torque at low speeds, which helps the motor maintain its position and drill the material in repeated movement.

-

3D Printers

A 3D printer is a highly advanced printer that has the ability to turn a digital design into physical objects by depositing layers of materials on each other.

The 3-phase stepper motor allows precise control over the movement of the 3D printer for depositing the materials layer by layer and is responsible for creating the intricate design with high accuracy. These motors can be programmed at different speeds and directions and allow printers to create intricate designs and patterns with multiple layers and different colours.

Permanent magnet stepper motors play an important role in various medical equipment such as MRI machines, and robotic surgery machines.

In MRI machines, these 3-phase stepper motors are responsible for moving the patient's table to scan different parts of the body. Also, these motors offer precision and accuracy, which help to position the patient correctly and obtain clear and accurate images of different parts of the body.

In Robotic surgery arms, PM stepper motors provide the necessary power and torque for bone drilling and suturing. The precise movement of these motors enables robotic surgery arms to rotate and bend in different directions and provides the surgeon with better access and visibility of different parts of the body.

-

Textiles Machines

Permanent magnet stepper motor plays an important in the functioning of textile machines. From spinning to weaving, dyeing, and finishing, these 3-phase stepper motors are used in every stage of manufacturing.

These motors use different stepping modes to move small steps in a controlled manner. This is crucial for textile machines, where even a small error will result in defective products. This ensures that each movement is accurate and results in high-quality products.

As textile machines, run for long hours and undergo frequent start and stop cycles. PM stepper motors have a simple design with fewer moving parts, reducing the chances of breakdown and maintenance issues resulting in minimizing the downtime and maintenance cost.

Factors for Selecting a Permanent Magnet Stepper Motor

When we need to select a permanent magnet stepper motor for our applications, we need to consider various factors to ensure it meets the specific requirements and performance of the applications.

Here are some important factors that need to be considered while selecting a permanent magnet stepper motor for your application.

-

Step Angle

It is referred to as an angular distance covered by a motor in one step or movement. This factor is important in the functioning of various types of applications such as robotics, CNC machines, and printers.

In robotics, the step angle of the motor determines the accuracy and speed of the movement of the robotic arm. A small step angle means the robot moves in small steps with precise control and accuracy which is essential for performing the detail and crucial tasks.

In a CNC machine, the step angle of the motor determines the size of the cuts and the movement of the machine. A small step angle results in finer and more precise cuts resulting in producing a high-quality product.

-

Torque and Holding Torque

A torque is a rotational force generated by the motor to rotate an object at a specific angle. An excellent torque of the motor results in the smooth and precise movements of the applications. PM stepper motors offer excellent torque and help various applications such as medical devices, and robotic arms where precise control is required to perform a specific task with accuracy.

Holding torque is referred to as the amount of torque a motor can maintain when it is not moving. It is required for a motor to hold its position without any external mechanism.

Various applications such as robotic arms, CNC machines, and 3D printers require high holding torque. The PM motor offers high-holding torque which helps these applications to perform tasks with precision

- Voltage and Current Supply

In the manufacturing industry, the voltage and current supply are used to power the machinery for an efficient production process. In medical equipment, the voltage and current supply are essential for applications such as ventilators and defibrillators to function continuously.

Voltage and the current supply are also important in large-scale applications, such as power plants for the safe generation of electricity.

-

Speed

Speed is referred to as the rotational speed at which a motor rotates and performs a specific task.

In industrial machinery, the speed of the motor is important for determining the output of the machinery. The higher the speed of the motor, the faster the machine operates, and this results in high productivity.

The speed of the motor also impacts the precision and accuracy of applications. In applications such as robotics and CNC machines, speed plays a crucial role in controlling the movement of the machine.

By evaluating the above factors, one can select the right permanent magnet stepper motor to meet specific needs and ensure the optimal performance of the application.