A Comprehensive Guide on Stepper Motors

Stepper motor is an electrical motor that converts electrical pulses into precise mechanical movements. It operates on DC power and moves in discrete steps. Stepper Motors offers various advantages such as precise positioning, high reliability, and ease of control and is used in applications such as CNC machines, robotics, 3D printers, etc.

What is a Stepper Motor?

A stepper motor is an electrical motor that converts electrical pulses into precise mechanical movements. Unlike other motors, which rotate continuously, the stepper motor moves in discrete steps allowing for position, speed and torque control.

Each step of the stepper motor corresponds to a fixed rotational angle determined by the motor’s design. A stepper motor consists of two main parts: stator and rotor. The stator is the stationary part of the stepper motor. It consists of multiple coils arranged in phases. The rotor is the rotating part of the stepper motor. It is made up of permanent magnets. Its teeth align with the magnetic field generated by the stator’s coil, allowing for precise and discrete steps.

Watch the YouTube Video by "JAES Company " for a better understanding about stepper motors

A stepper motor operates on the principle of electromagnetic induction. When electrical pulses are supplied to the stator’s coils, they generate the magnetic field. As the pulse sequence changes, the rotor moves in precise steps each corresponding to pulses. By adjusting the pulse frequency and sequence, the stepper motor’s speed and direction can be controlled making them ideal for precise positioning applications.

Stepper motors are widely used in applications such as CNC machines, 3D printers, robotics, and camera platforms where precision is required. Stepper motors also offer excellent repeatability and hold their position which makes them ideal for applications that require accurate and controlled motion.

Is the Stepper Motor AC or DC?

A stepper motor operates on DC power because it relies on precise control of DC pulses to move. This motor moves in discrete steps with each step triggered by the specific sequence of DC power. The DC power allows the stepper motor driver to generate and control these pulses with specific timing which is essential for accurate positioning, speed and direction control.

On the other hand, AC power naturally alternates its direction at a fixed frequency which disrupts the precise timing and sequence of pulses needed for stepping. Additionally, the constant fluctuation of AC power makes it difficult to maintain a stable magnetic field required to hold the rotor in a fixed position between steps for precise positioning.

Therefore, stepper motors are designed to operate with DC power, which provides the controlled and stable environment necessary for their precise operation.

Working of Stepper Motor

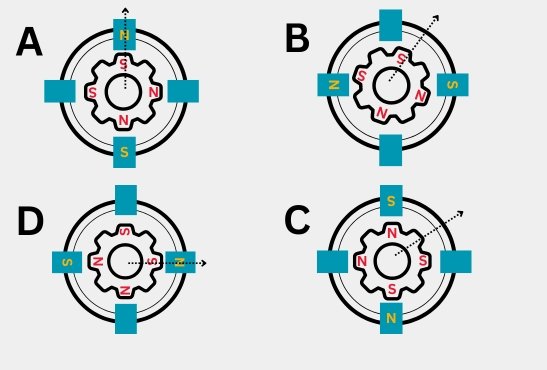

A stepper motor operates by converting electrical pulses into mechanical movements. It consists of a stator with multiple coils and a rotor with a permanent magnet. When the pulse is sent to the stator’s coils it creates a magnetic field that attracts the rotor and causes it to rotate in discrete steps.

The stepper driver or controller sends the pulse in a specific sequence to different coils to energise the different phases of the stator. As the magnetic field is generated by the phases of the stator, the rotor is moved from one aligned position to the other, making it a small step.

By varying the frequency of pulses, the speed of the stepper motor can be controlled and by changing the sequence of pulses, the direction of the stepper motor can be controlled. Stepper motors are known for their ability to maintain position without the need for a feedback system which makes them ideal for applications that require precise positioning.

Why is a stepper motor used?

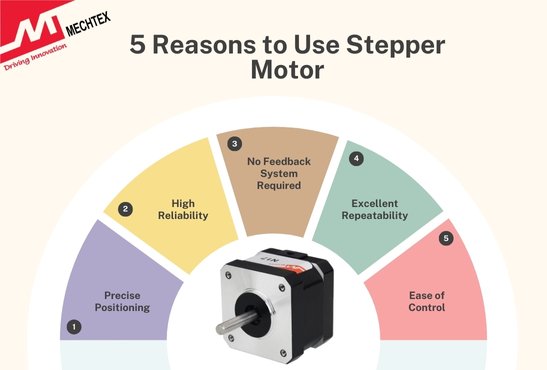

Stepper motors are widely used in various applications because of the numerous advantages they offer during their operation. Here are some key reasons for using stepper motors in various applications.

- Precise Positioning

One of the key reasons for using stepper motors is their ability to precise positioning. This ability allows stepper motors to move in discrete steps and provide highly accurate control over the position of the motor.

This precise positioning ability makes stepper motors ideal for tasks that require accurate positioning such as CNC machines, and 3D printers where movement must be controlled accurately.

- No Feedback System Required

Stepper motors do not require feedback devices to maintain their position. Unlike servo motors, which rely on encoders or controllers to determine the position of the rotor, stepper motors can hold their position precisely without any feedback system.

This simplifies the design of the stepper motor and makes it an ideal option for a wide range of applications.

- High Reliability

Stepper motors are also known for their high reliability. As their design does not consist of brushes and commutators which are the common points of wear and tear in any other type of motor. It leads to longer operational life and high durability of stepper motors. This makes stepper motors suitable for industrial applications where long-term reliability is essential.

- Excellent Repeatability

Stepper Motors offers excellent repeatability which means they can run in the same position repeatedly with accuracy. This is particularly important in applications like robotics and automated assembly lines, where consistent, repeatable movements are crucial for quality and efficiency.

- Ease of Control

Stepper motors are easy to control with digital signals which makes them compatible with microcontrollers and make them easy to integrate with complex systems. This versatility and precision make them a preferred choice in many precision-driven applications.

Also Read

Conclusion

Stepper motors are an invaluable component in the world of automation. Their ability to provide precise control of movement, high reliability, and ease of use, makes them a popular choice for applications like 3D printing and robotics. Whether you're looking for accuracy, consistency, or a dependable motor for your project, stepper motors are the most suitable motors to achieve outstanding results.