Advantages & Disadvantages of Synchronous Motors: Constant Speed, Efficiency & Drawbacks

Understand the key advantages and disadvantages of synchronous motors, from constant speed and high efficiency to non-self-starting behaviour, need for DC excitation, limited speed control, and higher cost.

What is a Synchronous Motor?

A synchronous motor is a type of AC motor, that maintains its constant speed synchronised with the frequency of current supply. Unlike induction motors, where the rotor lags behind the rotating magnetic field of the stator. Synchronous motors operate at a constant speed without any lag. This means the rotor’s speed exactly matches the synchronous speed matches with the frequency of supply and number of poles. This makes synchronous motors an ideal solution for applications that require precise and constant speed, under varying load conditions.

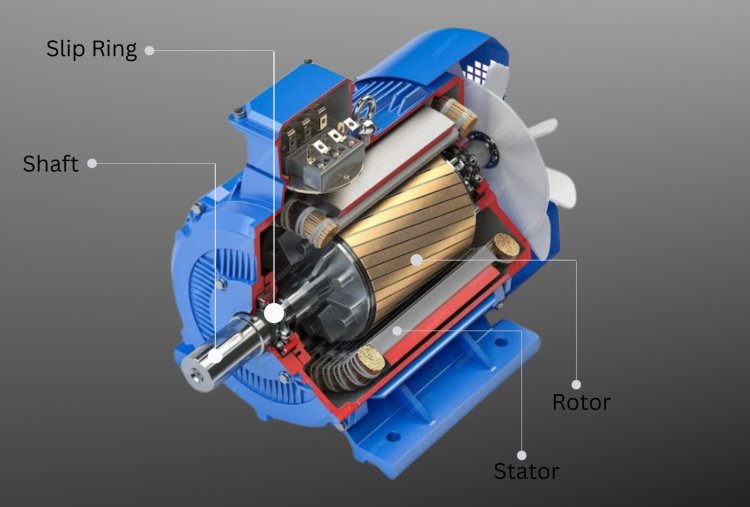

The construction of a synchronous motor consists of two main components: stator and rotor. The stator is the stationary part of the motor and consists of three-phase windings connected to the AC supply. The rotor is the rotating part of the motor that consists of electromagnets to produce a magnetic field.

The working principle of a synchronous motor is based on the interaction between the rotating magnetic field produced by the stator and the magnetic field of the rotor. When a motor is powered with an AC supply, the stator generates a magnetic field. The rotor is brought close to the same speed as the rotating magnetic field using starting methods such as using damper windings, using external sources and others. Once the rotor reaches its speed it locks with the stator’s magnetic field and rotates at the same speed. It is known as synchronous speed.

The synchronous speed of the synchronous motor is determined by the supply frequency and the number of poles in the motor, and it can be calculated using the formula:

Ns = 120xf/P

Where,

Ns = Synchronous Speed (in RPM)

f = Supply frequency (in Hz)

P = Number of poles

However, Synchronous motors are not self-starting because the rotor cannot immediately synchronise with the rotating magnetic field of the stator when the motor is powered on. At standstill, the rotor lacks sufficient torque to catch up with the high-speed rotating magnetic field. This limitation requires additional starting mechanisms, such as damper windings, external motors, or variable frequency drives, to bring the rotor up to synchronous speed.

Therefore, Synchronous motors are particularly useful for applications requiring constant speed, such as clocks and timers, industrial machinery and others as they maintain a precise rotational speed regardless of load variations.

Also Read

Introduction of Synchronous Motor

Advantages of Synchronous Motors

Synchronous motors offer several advantages, making them suitable for a wide range of applications. Here are the key benefits:

- Ability to maintain a constant speed

One of the major advantages of the synchronous motor is its ability to maintain constant speed under various load conditions. It means these motors can maintain a constant speed even when the amount of load changes making it ideal for various industrial and commercial applications.

The synchronous motor maintains a constant speed through the synchronisation of the rotor and stator. When electrical current flows through the stator, it generates a magnetic field that interacts with the magnetic field produced by the rotor and causes the rotor to rotate at the same speed as of the magnetic field. This ensures a relationship between the stator and rotor, resulting in smooth and steady operation.

This unique advantage makes synchronous AC motors ideal for applications such as pumps, compressors, and fans where precise and constant speed is required.

- High Efficiency

Synchronous motors maintain a constant speed regardless of load. Unlike other motors, which may experience slip and loss of efficiency at partial load, synchronous motors operate at high efficiency across the entire operating range due to their ability to operate at synchronized speed.

By adjusting the current supplied to the rotor, synchronous AC motors actively control their power factor. This allows them to correct any leading and lagging power factor resulting in optimizing efficiency and reducing energy losses.

Small synchronous motors are ideal for precise applications like timers, instrumentation, and robotics due to their accurate speed control and reliability.

- High Starting Torque

Synchronous motors generate a significant amount of torque, allowing them to quickly accelerate heavy loads, without the need of any external starting source such as starters or frequency drives.

The high starting torque ensures smooth and steady acceleration of the motor and minimizes the risk of wear and tear. It results in a longer life span and reduces maintenance costs.

Synchronous motors with high starting torque are ideal for applications that require high inertia loads such as large fans, pumps, or conveyor belts. They can overcome the load easily and bring them to operate quickly and efficiently.

- Long LifeSpan

The most significant advantage of synchronous motors is they have a long lifespan. Unlike other motors, synchronous motors have robust and durable construction, which allows them to operate in heavy loads and harsh environments conditions.

Additionally, synchronous motors have a simple design with fewer moving parts, which reduces the chances of wear and tear and increases lifespan. Furthermore, synchronous motors have a high load-carrying capacity means they can handle heavy loads without affecting the performance and efficiency of the motor.

This makes synchronous AC motors reliable and long-lasting solutions for various industrial and commercial applications.

- Smooth and quiet Operation

Synchronous motors have a unique advantage over the other motors in that they have a smooth and quiet operation. Synchronous motor stator and rotor create a constant magnetic field which allows them to rotate at a constant speed without any load. This results in less vibrations and quiet operation.

Additionally, synchronous motors have a high power factor means they require less energy during operation which contributes to smooth and quiet operation.

Furthermore, synchronous motors lack mechanical commutators which eliminate the sparking and friction and cause noise in motors.

This makes them ideal for use in applications such as medical equipment, audiovisual systems, and residential or office buildings where noise levels must be minimal.

Disadvantages of Synchronous Motors

Synchronous motors are highly efficient and precisely operated motors. They have several disadvantages which makes them less suitable for certain applications compared to other types of motors. Here are the some demerits:

- High Cost

One of the most significant disadvantages of synchronous motors is the high cost. These motors involve complex construction and precision engineering making them more expensive as compared to other types of motors. The stator and rotor must be precisely designed and aligned to ensure the synchronous motor runs smoothly at a constant speed.

Additionally, synchronous motors are made up of high-quality materials such as copper and rare earth magnets which makes them expensive in manufacturing as compared to other types of motors.

This high cost makes the synchronous AC motors less accessible for small businesses and individuals with minimal budgets.

- Need a Separate power source for excitation

Another major disadvantage of synchronous motors is they need a separate power source for excitation. It means in addition to the main power source, synchronous motors require a separate power source is required to create a magnetic field that allows motors to operate at constant speed.

This is the significant drawback of synchronous motors as it not only adds complexity to their construction but also increases the cost of the motor. Furthermore, if excitation fails, the synchronous motor will not function properly resulting in high downtime and potential losses.

Additionally, the use of separate power sources makes synchronous motors less adaptable to various industrial and commercial applications.

- Limited Speed Control

Another significant disadvantage of synchronous motors is they have limited speed control. Unlike other types of motors, synchronous AC motors require a constant current supply at a specific frequency to maintain their synchronous speed. It means their speed cannot be varied easily. It makes them less suitable for applications that require precise speed control.

The speed of synchronous motors can be varied within the range of 5% to 10% leading to additional equipment and increased cost to maintain precise speed control. This inability to vary the speed results in reduced efficiency and increased wear and tear on the synchronous motor.

- Not Self-Starting

One of the major disadvantages of synchronous motors is they are not self-starting. It means they require an external source of power to start and rotate. It can be a significant drawback as it makes synchronous motor structures more complex and adds extra cost to the motor system.

Furthermore, a synchronous motor requires speed control to maintain its synchronised speed, adding an external power source leads to inability and potential damage to synchronous motors if variations in power supply are not properly managed for synchronised speed.

Therefore the lack of self-starting capability of synchronous motors limits their usability and adds challenges in operations.

Also Read

Why Synchronous motor is not Self Starting

- Sensitivity to changes in load

Another disadvantage of synchronous motors is they are sensitive when the load is changed. It means any sudden increase or decrease in load on the motor greatly affects the performance and efficiency of the motor. It is due to synchronous motors fixed speed. As synchronous motor operates at a synchronous speed determined by the frequency of the power supply.

Any change in load may affect its synchronous speed, resulting in a decrease in torque and an increase in power consumption leading to overheating and causing failures in many cases.

Additionally, it is difficult to control the speed of the motor when the load is changed which creates a problem for applications that require precise speed control.

Conclusion

Synchronous motors offer various advantages such as precise speed control, high efficiency, stable operation, and long lifespan. This characteristic makes synchronous motors suitable for various industrial and commercial applications where constant speed is required.

However, the synchronous motor also comes with some drawbacks such as high cost, the need for a separate power source for excitation, limited speed control, and difficulty in starting. These drawbacks add challenges to operations and limit the usability of synchronous motors for various applications.

Despite these limitations, synchronous motors are irreplaceable solutions in various sectors especially where constant speed and efficiency are required. Advanced technology has addressed some of the disadvantages of synchronous motors and made them adaptable to a wide range of applications. Ultimately, the choice of motor type depends upon the need of the application which determines the most suitable solution.