How BLDC Motors Are Powering the EV Revolution

BLDC motors are at the heart of the EV revolution. Their high efficiency, compactness, and reliability make them the motor of choice for a wide range of electric vehicle applications.

The global transition towards electric vehicles (EVs) is one of the most defining industrial shifts of the 21st century. As the automotive sector focuses on reducing carbon emissions, improving energy efficiency and achieving sustainable mobility, the demand for advanced motor technologies has surged.

Among these Brushless DC motor (BLDC Motor) has emerged as a key component of the EV revolution. Their high efficiency, compact design, and superior performance make them ideal for modern electric vehicles (EVs).

In this blog, we will explore how BLDC motors are transforming the EV industry, why they are ideal, challenges in adoption and the future outlook of BLDC motors in EVs.

Understanding BLDC Motors for EVs

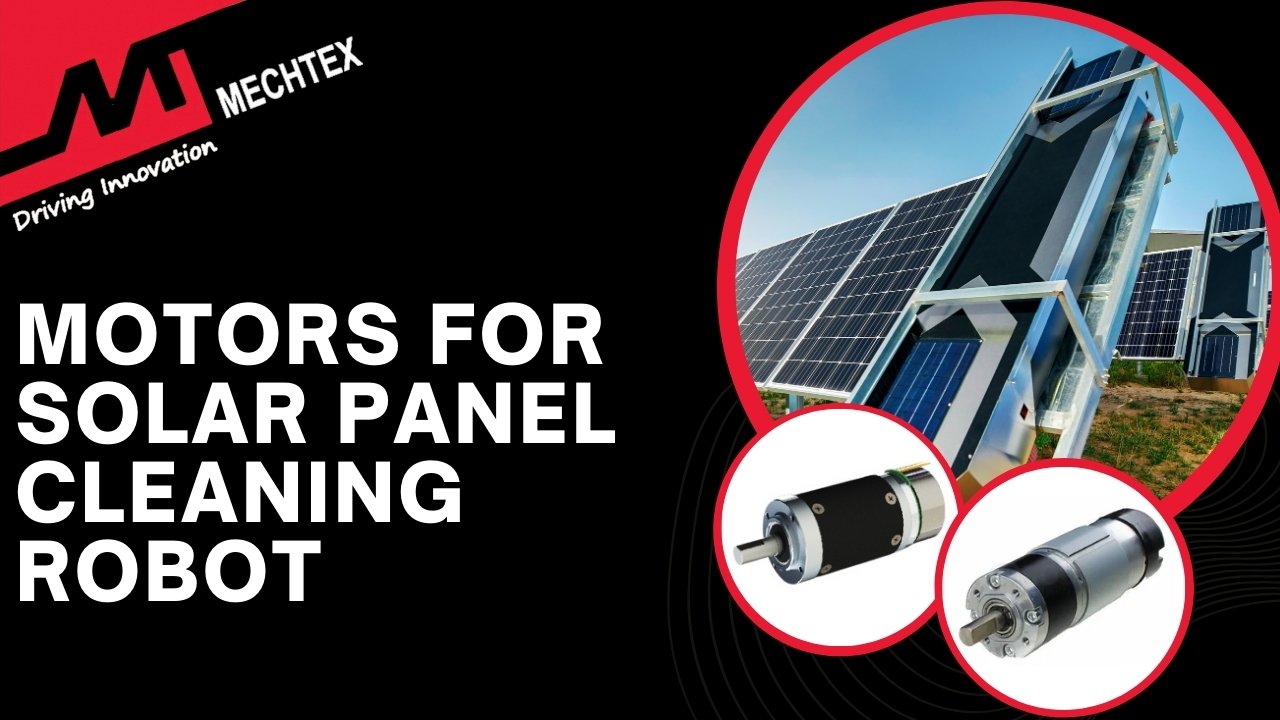

Brushless DC motors are the central component in the architecture of electric vehicles (EVs). These motors are electronically commutated and operate using a permanent magnet rotor and a 3-phase winding stator.

In EV applications, the motor’s rotation is controlled through signals from the electronic controller that synchronise the current flow to generate desired motion.

In an EV system, the BLDC motor is tightly integrated with the vehicle's power electronics. The Brushless DC motor receives three-phase electrical input from the inverter, which is powered by EVs battery pack.

The inverter converts the DC power from the battery into AC signals to control the motor’s speed and torque. This interaction ensures precise control over propulsion and regenerative braking functions.

The design and winding configurations of BLDC motors used in EVs are tailored for high torque at low speed and consistent performance across a wide range. Additionally, the sensor or sensorless feedback mechanism helps monitor rotor position, which is crucial for accurate commutation timing.

In the context of EVs, BLDC motors are not just propulsion units but key elements that interact with complex electronic systems to deliver controlled, stable, and reliable vehicle operation.

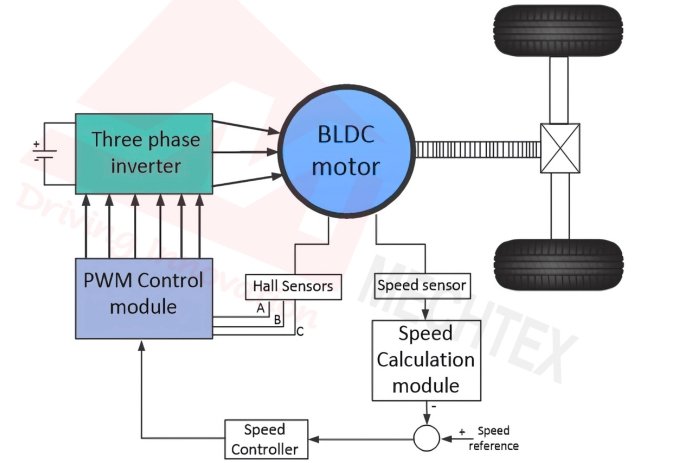

Why BLDC Motors Are Ideal for EVs

Several features of BLDC motors make them particularly suited for electric vehicles:

- High Efficiency

BLDC motors can achieve an efficiency of 85% to 90%, significantly outperforming brushed DC motors and even many AC induction motors. This high efficiency is crucial for EVs, where maximising battery usage directly translates into longer drive range.

- Compact and Lightweight Design

EVs require compact, lightweight motors to reduce overall vehicle weight and improve energy efficiency. BLDC motors, especially inrunner BLDC motors, offer high power density, allowing manufacturers to design smaller motors without compromising performance.

- Excellent Torque Characteristics

BLDC motors provide high starting torque and consistent torque for a wide range of speeds, which is essential for electric vehicles (EVs) for acceleration and high climbing. This smooth and strong torque output enhances the driving comfort and vehicle performance.

- Low Maintenance and Long Life

The absence of brushes reduces mechanical wear and tear, significantly increasing the motor’s life span. This also minimises maintenance costs, which is a major benefit for EV owners and fleet operators.

- Precise Speed and Position Control

BLDC motors offer excellent controllability through an electronic speed controller (ESC). This allows precise control over BLDC motor speed and position, improving vehicle handling, regenerative braking and energy optimisation strategy.

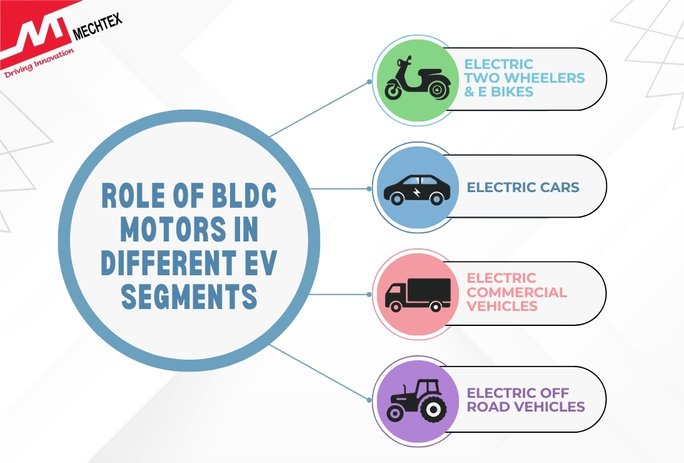

Role of BLDC Motors in Different EV Segments

BLDC motors are used in a wide range of electric vehicles, from two-wheelers to commercial EVs:

- Electric Two-Wheelers and E-Bikes

The lightweight and compact size of BLDC motors makes them ideal for e-bikes, scooters, and motorcycles. Hub-mounted BLDC motors are common in this segment due to the ease of integration and direct drive capability.

- Electric Cars

In electric vehicles, BLDC motors are used for both propulsion and auxiliary applications such as power steering, HVAC systems, and window mechanisms. Some compact electric cars use BLDC motors for main propulsion due to their high torque and compactness.

- Electric Commercial Vehicles

BLDC motors are being adapted for electric delivery vans, buses, and material handling vehicles, where reliability, energy efficiency and high torque output are crucial.

- Electric Off-Road and Utility Vehicles

BLDC motor finds applications in golf carts, AGVs (Automated Guided Vehicles), and farming machinery, supporting the electrification of off-highway mobility.

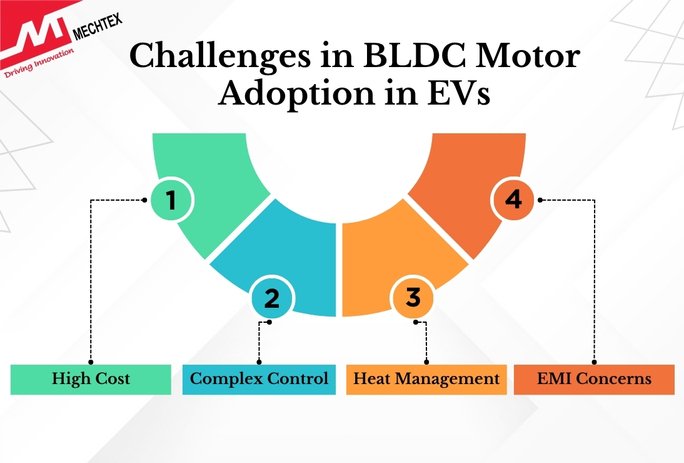

Top Challenges in BLDC Motor Adoption in EVs

Brushless DC (BLDC) motors have become a preferred choice in electric vehicles (EVs) due to their efficiency, compact size, and long service life. However, integrating BLDC motors into EV platforms isn’t without obstacles.

As EV adoption increases, manufacturers must navigate several technical and economic challenges to ensure performance, affordability, and reliability.

Below are the top five challenges hindering widespread BLDC motor adoption in EVs:

- High Initial Cost of Materials and Components

The BLDC motor relies heavily on rare earth magnets such as neodymium or samarium-cobalt, which significantly drive up production costs. These materials are not only expensive but also sensitive to the global supply chain fluctuations. For EVs competing in cost-sensitive markets, this becomes a key barrier to scale.

- Complex Motor Control and Electronics

Unlike traditional motors, BLDC motors require electronic controllers to manage communication and speed. Designing and integrating sophisticated control algorithms, sensor feedback, and power electronics increases complexity, development time and cost, especially in high-performance EV applications.

- Thermal Management Challenges

In EVs, BLDC motors operate under varying load conditions, often generating substantial heat. Without effective thermal management systems, motors can overheat, leading to reduced efficiency or even permanent damage.

- Electromagnetic Interference (EMI) Concerns

The high-frequency switching in BLDC motor controllers can generate magnetic interference, affecting other sensitive vehicle electronics such as infotainment systems, BMS, or sensors.

Future Outlook: BLDC Motors and EV Innovation

The role of BLDC motors in shaping the future of electric mobility is undeniable. As EV manufacturers focus on improving efficiency, reducing weight, and enhancing driving dynamics, BLDC motor technology will continue to evolve with:

- Integration with IoT for predictive maintenance

- Sensorless control algorithms to reduce system cost

- Improved cooling systems for higher power ratings

- Material innovations like high-performance magnets and thermally conductive composites

Additionally, as battery technology advances and power electronics become more efficient and affordable, the synergy with BLDC motors will further enhance EV performance and accessibility.

Conclusion

BLDC motors are at the heart of the EV revolution. Their high efficiency, compactness, and reliability make them the motor of choice for a wide range of electric vehicle applications. As the automotive industry accelerates toward electrification, the importance of BLDC motors will only continue to grow.

From powering electric scooters on city roads to driving high-performance EVs on highways, BLDC motors are silently and efficiently powering the future of mobility.