Static Torque vs. Dynamic Torque in Stepper Motors

Learn the key differences between static and dynamic torque in stepper motors and why both are critical for precision, speed, and reliable motor performance.

Stepper motors are known for their precise control, speed, and acceleration. They are widely used in applications such as 3D printers, CNC machines, robotics, and medical devices.

However, to fully leverage the capabilities of the stepper motor, it is important to understand one of its core performance indicators called “torque”

It is broadly classified into two types: static torque and dynamic torque. Understanding the difference between these two types of torque, their significance, and their unique role in operation helps engineers select the right stepper motor for applications.

What is Torque?

Torque is the rotational force that enables the motor to move and hold its position accurately. It defines how much mechanical load the motor can drive or hold at any given time. In stepper motor, torque directly influences the performance and reliability in precision applications. It is measured in Newton-meters (Nm) or ounce-inches (oz-in), depending on the unit system.

There are two main types of torque in stepper motor: static torque and dynamic torque. Selecting stepper motors with sufficient torque is essential to prevent missed steps and ensure smooth operation.

What is Static Torque?

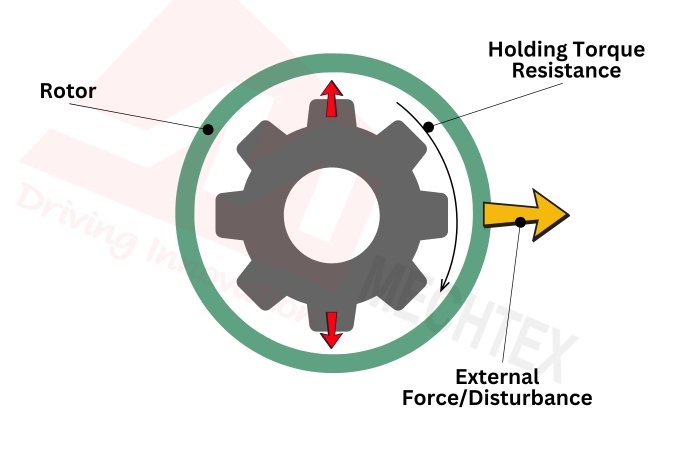

Static torque is commonly referred to as holding torque. It is the critical parameter for stepper motors. It is the torque the stepper motor can hold at a fixed position under load, ensuring that the rotor remains stationary despite the presence of an external load.

In simple terms, it represents the maximum torque a stepper motor can resist without any movement. It is the defining characteristic of stepper motors which makes them ideal for applications that require precise positioning.

The static torque is produced when current flows through the motor windings and creates a magnetic field. This magnetic field locks the rotor into a specific position anbd allows it to maintain the position even in the presence of an external load.

It is essential for applications where the load must be held securely without any movement, such as CNC machines, 3D printers, and robotic arms.

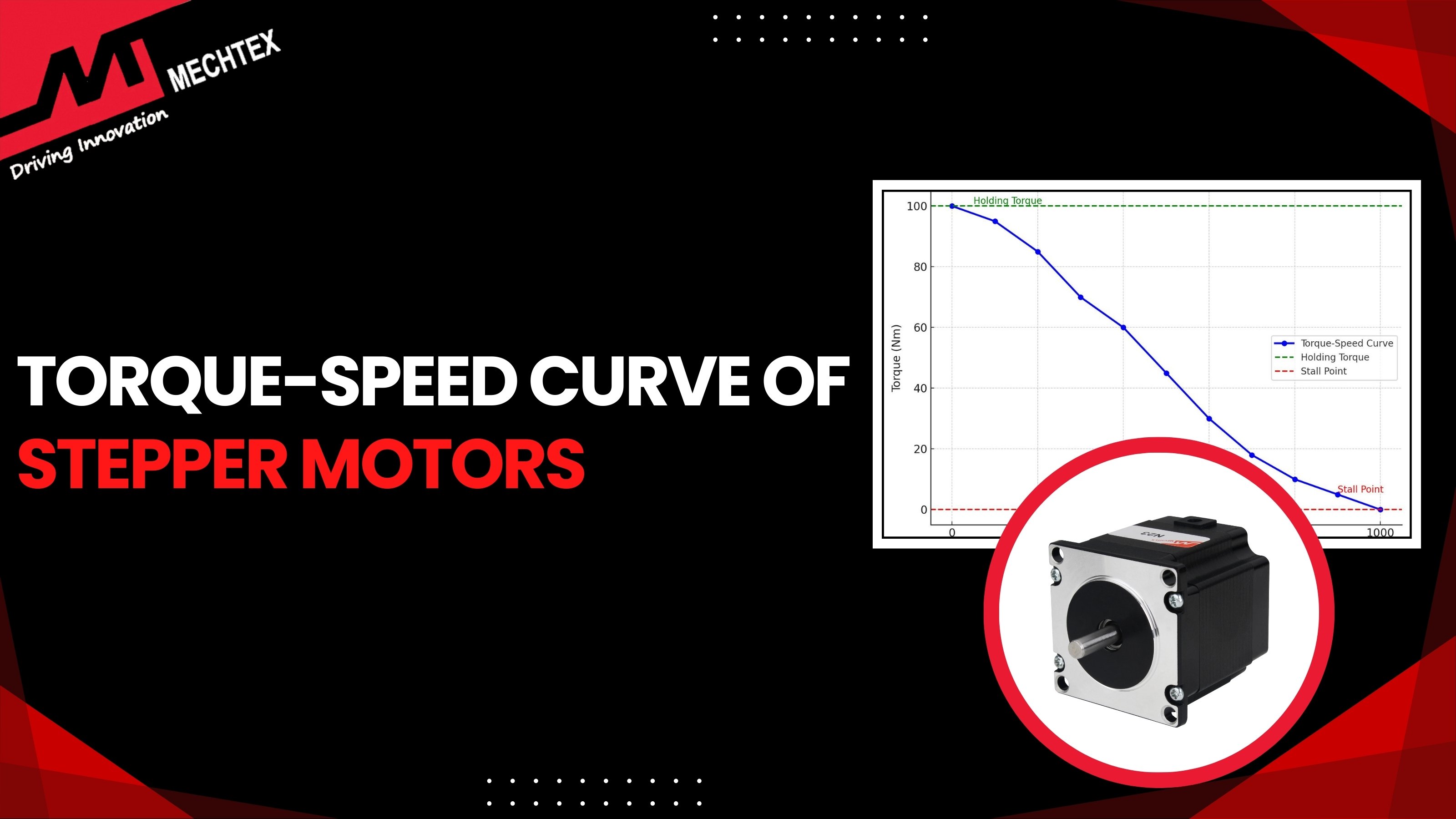

Static torque is the highest torque rating of stepper motor and decreases with increasing speed. Hence, engineers must consider both the holding torque and the torque-speed characteristics when designing motion control systems using stepper motors.

What is Dynamic Torque?

Dynamic torque refers to the torque generated when the stepper motor is in motion. It means generated when the stepper motor is stepping from one position to another.

Unlike static torque (holding torque), which applies when the motor is stationary. At the same time, dynamic torque reflects the motor's ability to deliver the rotational force during operation.

It is crucial for determining how much load the stepper motor can handle and how it moves at different speeds without losing steps.

As the stepping frequency increases, the dynamic torque decreases. It is due to the inductance of the motor winding, which limits the stepping rates. At higher speeds, it generates low torque as there is less time for current to flow in each coil during each step and build a low magnetic field.

In practical terms, dynamic torque determines how fast and how heavy a stepper motor can be while maintaining its position.

If the dynamic torque is insufficient for the application, the motor may miss steps or stall. Therefore, understanding a motor’s dynamic torque curve is essential when selecting a motor for applications involving motion, such as automated conveyors, 3D printers, or pick-and-place systems.

Static Torque vs. Dynamic Torque

Static torque and dynamic torque are two parameters that define the stepper motor’s performance.

Understanding the difference between these two parameters is essential for selecting the right stepper motor for a specific application.

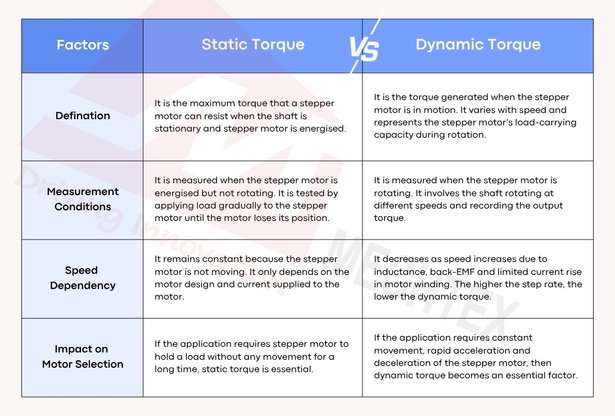

- Definition

Static Torque: It is also known as holding torque. It is the maximum torque that a stepper motor can resist when the shaft is stationary and the stepper motor is energised.

Dynamic Torque: It is the torque generated when the stepper motor is in motion. It varies with speed and represents the stepper motor’s load-carrying capacity during rotation.

Measurement Conditions

Static Torque: It is measured when the stepper motor is energised but not rotating. It is tested by applying load gradually on the stepper motor until the motor loses its position.

Dynamic Torque: It is measured when the stepper motor is rotating. It involves the shaft rotating at different speeds and recording the output torque.

- Speed Dependency

Static Torque: It remains constant because stepper motor is not moving. It only depends on the motor design and current supplied to the motor.

Dynamic Torque: Depends on the speed of the stepper motor. It decreases as speed increases due to inductance, back-EMF and limited current rise in motor winding. The higher the step rate, the lower the dynamic torque.

- Impact on Motor Selection

Static Torque: If the application requires stepper motor to hold a load without any movement for a long time, static torque is essential.

Dynamic Torque: If the application requires constant movement, rapid acceleration and deceleration of the stepper motor, then dynamic torque becomes essential and a deciding factor in application performance.

- Practical Application

Static Torque: It is crucial for applications that require precise holding, such as automated positioning systems and camera gimbals.

Dynamic Torque: Required for applications such as conveyor systems, robotic arms, and CNC tools, where the motor must exert force to overcome inertia and friction while moving.

Conclusion

Understanding the distinction between static and dynamic torque in stepper motors is essential for effective motor selection and system design. While static torque ensures positional stability when the motor is at rest, dynamic torque determines whether the motor can maintain synchronisation during motion.

Both types of torque play a crucial role in ensuring stepper motor-driven systems operate smoothly, reliably, and efficiently. By considering both aspects in design and specification, engineers can build systems that perform precisely as intended, whether the motor is moving or standing still.