Understanding Different Types of Encoders

Different types of encoders like Incremental, Absolute, Linear, Rotary, and Optical encoders work on a distinct working principle and offer different advantages. Understanding them enables us to select the right technology for specific applications

In modern motion control systems, encoders play an important role in ensuring precision, feedback, and synchronisation for smooth performance.

Whether it's a robotic arm, conveyor belt, or other applications, encoders convert mechanical movements into electrical signals and allow control systems to track position, speed and direction accurately.

In this blog, we will explore different types of encoders, their working principles and the advantages offered by them to get a clear understanding of how each type of encoder supports different industrial needs.

What is an Encoder?

An encoder is an electromechanical device that converts motion into electrical signals and interprets them to the control system. It provides precise feedback about the speed, direction, and position of the motor.

Encoders work by detecting changes in the physical properties of the motor, such as rotation and movement, and translating them into digital signals. These signals help the controllers to monitor the performance of the system and make adjustments to improve accuracy.

Watch the YouTube Video by "RealPars" to get an overview of the encoder.

By providing real-time data, encoders help the controllers to prevent errors, improve efficiency and enhance reliability. It makes them an essential component for modern industrial applications, automotive, robotics, conveyor systems, and others, where motion detection and feedback are essential.

Also Read

Types of Encoders

An encoder is an important feedback device which converts movements into electrical signals and allows controllers to detect position, speed and direction to provide accurate feedback.

Each type of encoder works on a distinct working principle and offers advantages. Let’s explore the different types of encoders:

Incremental Encoders

Incremental encoders are motion-sensing devices used to monitor the movements of the motor. Unlike absolute encoders, incremental encoders do not provide feedback about a fixed position, but generate a series of pulses corresponding to the motion increments.

These pulses are interpreted by controllers, PLCs, and microcontrollers to track relative displacement and movements.

Incremental Encoders are commonly used in CNC machines and automation systems where compact design and precise monitoring are essential.

Working of Incremental Encoders

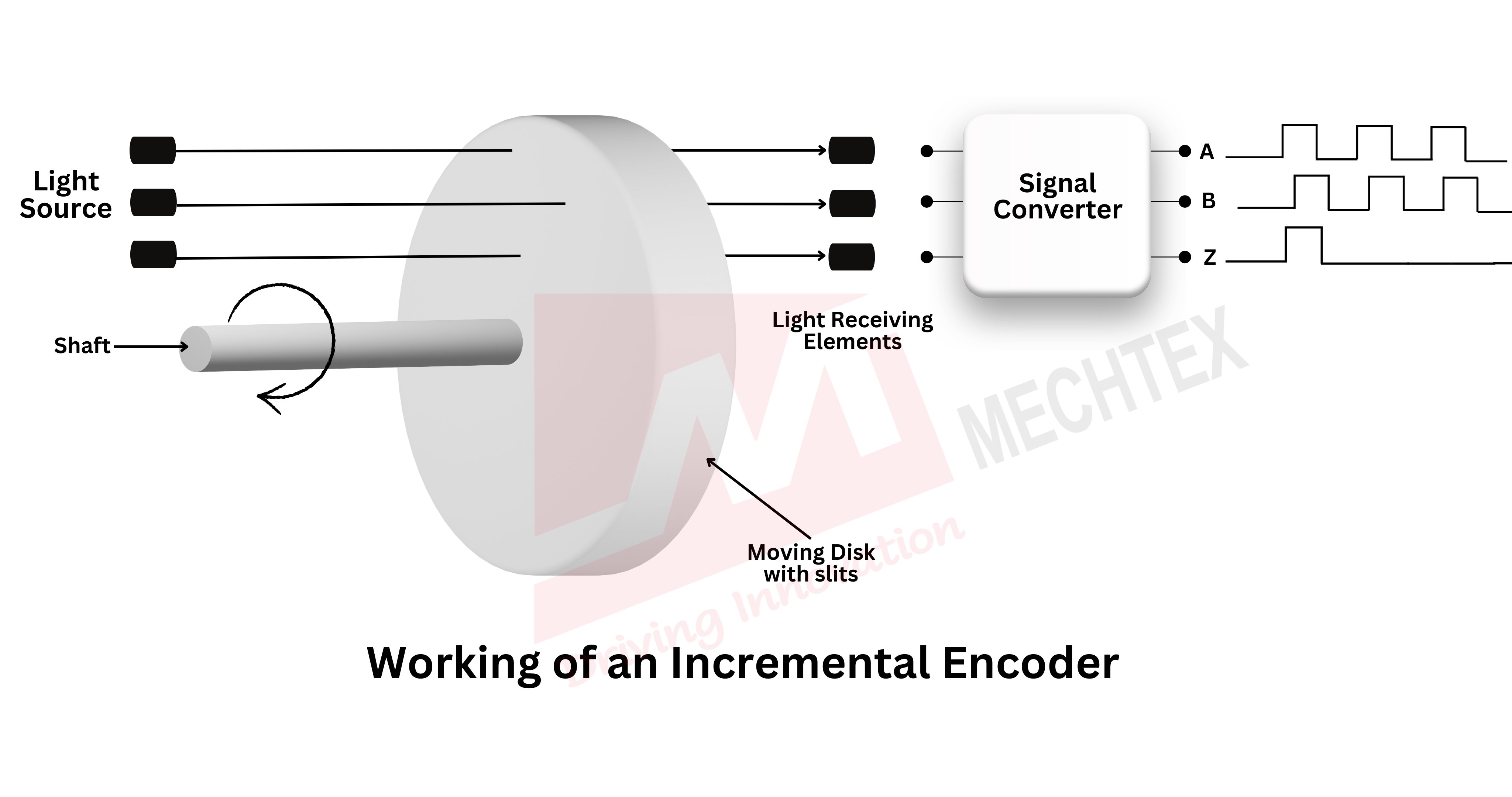

Incremental Encoders are devices which convert the rotational movement of the shaft into electrical signals and allow to provide accurate feedback.

They consist of a rotating disc marked with alternating transparent and opaque segments, along with a light source and detector.

As the shaft rotates, the disc interrupts the light beam and produces electrical pulses which allow to detect the speed and direction of the shaft. Many incremental encoders also include a reference or index pulse that marks the specific position in a full rotation.

By counting the pulses, controllers and microprocessors track the movement and provide accurate feedback.

Advantages of Incremental Encoders

- Simple Design and Cost-Effective

- High Resolution and Fast Response

- Suitable for accurate speed and direction measurement

Absolute Encoder

Absolute encoders are feedback devices designed to provide the exact position of the rotating shaft or other motion system.

Unlike incremental encoders, which only measure relative movements, absolute encoders provide a unique digital code to each shaft movement. It means that if the system loses power, the encoder immediately provides the details about the exact position of the motion system without any reinitialisation or reference.

Absolute encoders operate using optical, magnetic and capacitive technologies, depending on the application and its requirements.

Due to its capability to deliver precise, real-time feedback and recall data, absolute encoders are ideal for applications that require complex motion control systems such as robotics, industrial automation, elevators and others.

Working of Absolute Encoders

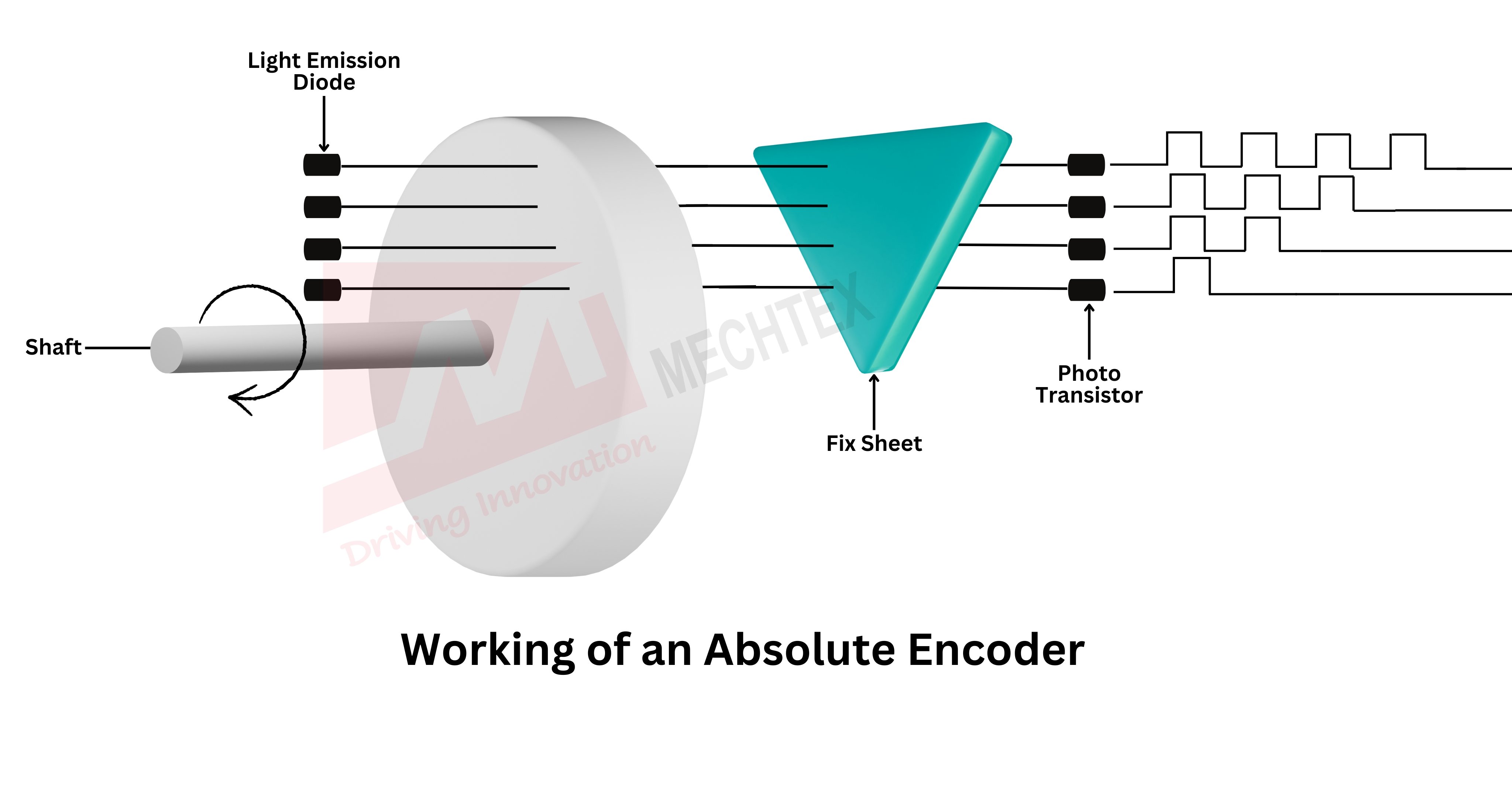

An absolute encoder provides a unique digital code for each shaft movement to ensure precise and non-repetitive readings. It consists of a rotating disc marked with multiple concentric tracks, with optical sensors. These tracks generate the binary code pattern corresponding to the specific angular movements.

The absolute encoders output a distinct value for every position, which enables accurate feedback upon startup of the system.

Advantages of Absolute Encoders

- Retains position immediately after power loss

- High accuracy and reliability

- No need for a reference point

Linear Encoder

Linear encoders are a type of encoder used to measure the linear displacement of motion system and provide accurate positioning and motion data along a straight path.

Unlike rotary encoders that track angular movements, linear encoders convert movements of the shaft or motion system into electrical signals representing a distance travelled in a linear direction.

By converting physical movements into electrical signals, linear encoders ensure precise control, accurate feedback and high reliability, which makes them ideal for applications such as CNC machines, coordinate measuring machines, and semiconductor equipment.

Working of Linear Encoders

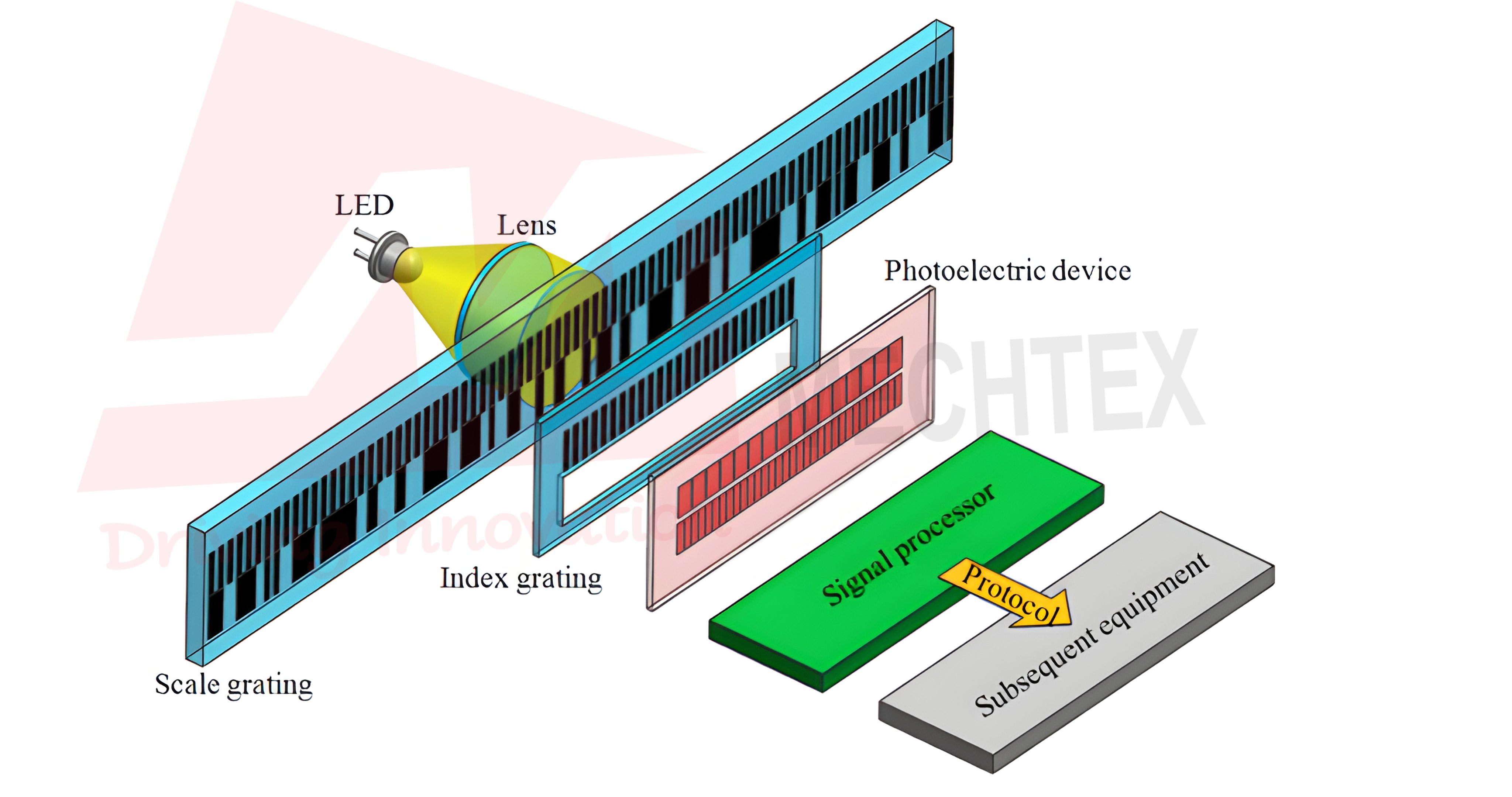

Linear encoders measure linear displacement by converting straight-line movements into electrical signals.

It consists of two main components: a scale and a redhead (also known as a sensor). As the redhead moves along the scale, it detects the changes in position of the shaft or motion system using optical, magnetic or inductive sensing principles.

These changes generate a digital or analogue signal corresponding to the linear movement and are then processed by the controller to determine the position, speed, and direction of the shaft.

Advantages of Linear Encoders

- High Resolution and Precision

- Ideal for linear positioning and measurements

- Low wear and tear and maintenance cost

Rotary Encoders

Rotary encoder is an electromechanical device which converts the motion of a shaft into electrical signals. It plays a crucial role in monitoring the rotational motion of the system in applications such as motors, actuators and automation systems.

Rotary encoders come in various designs based on their output signal and are commonly classified as incremental encoders and absolute encoders.

Incremental encoders generate pulses corresponding to the shaft movements, while absolute encoders provide a unique digital code. With the ability to deliver real-time data, rotary encoders become a crucial part of closed-loop control systems.

Working of Rotary Encoders

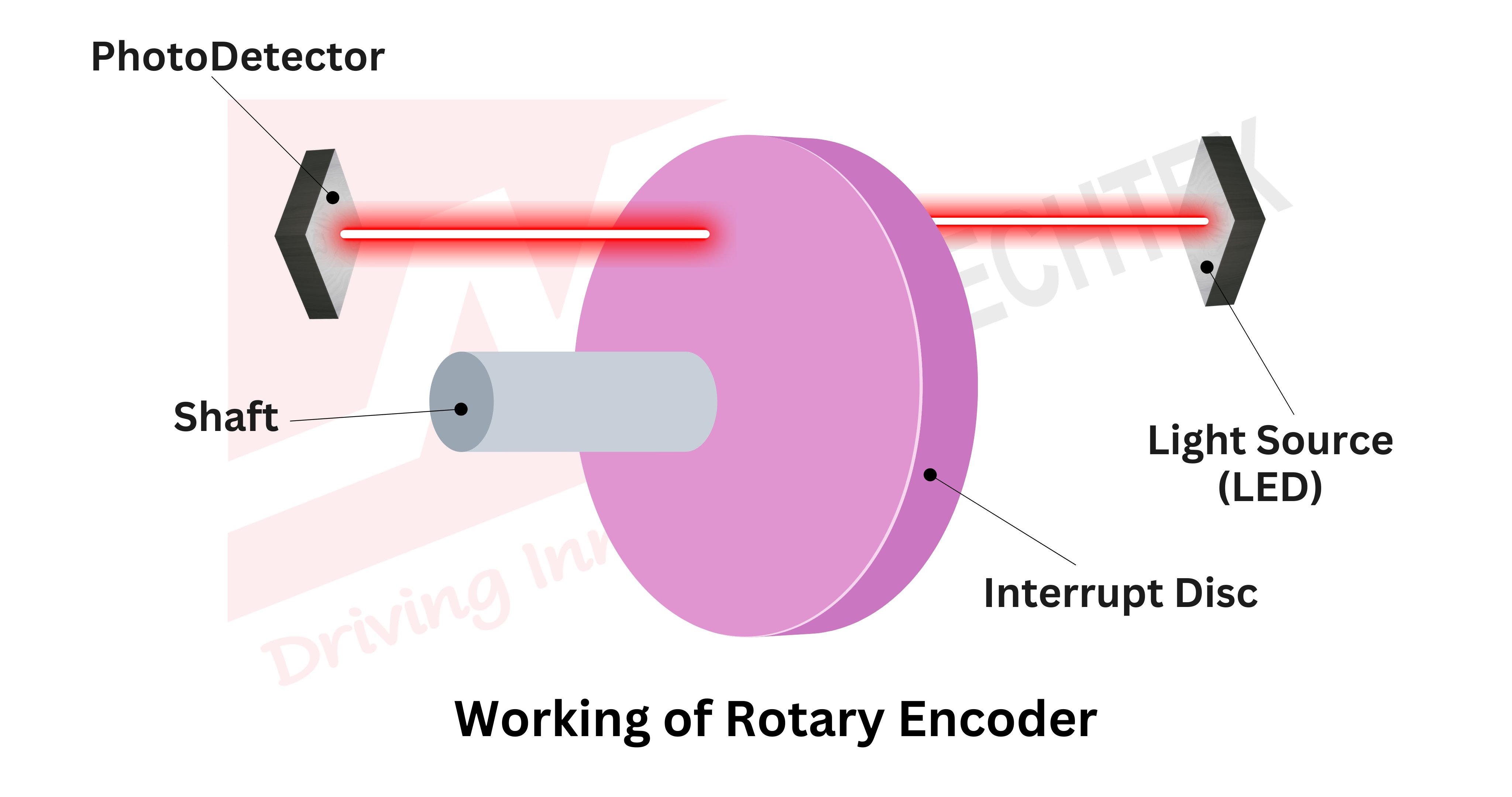

The working of a rotary encoder is based on detecting motion and converting it to electrical signals for control and smooth movement.

When the encoder’s shaft rotates, a disk with evenly spaced markings passes through a sensor. In an optical encoder, a light source and a photodetector detect the interruption of light made by the movement to generate a series of pulses.

Advantages of Rotary Encoder

- Compact and reliable

- Available in various resolutions

- Can operate in harsh environments (especially magnetic types)

Optical Encoders

An optical encoder is an encoder that uses light to detect the motion of the object and system. It operates by passing a light beam, usually made from an LED, through a coded disc and transparent scale.

As the disc rotates, the light is intermittently blocked and transmitted to the photodetector, photodetector detects these changes to generate the output signals to detect the position and angle of the shaft.

Optical encoders are known for their high precision and resolution, making them ideal for applications such as CNC machines, robotics, and industrial automation.

Due to their non-contact sensing principle, optical encoders ensure smooth operation with minimal wear and excellent repeatability.

Working of Optical Encoder

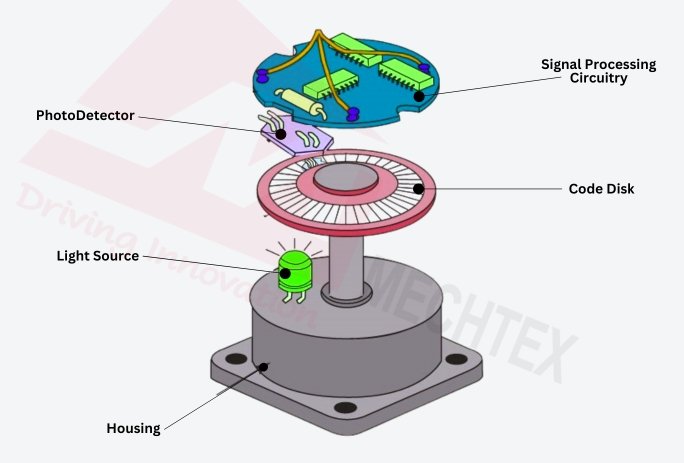

The working of an optical encoder is based on detecting light interruptions to measure position, speed and direction of the object.

Optical encoders comprise a light source (LED), photodetector, and a code disc with transparent or opaque segments. As the discs rotate with the shaft, the light passes through the transparent area of the disc and blocked by the opaque area.

Advantages of Optical Encoder

- High precision and resolution

- Excellent repeatability

- Ideal for clean and controlled environments

Conclusion

Encoders are the backbone of every precision motion control system. From ensuring accurate motor feedback to maintaining synchronisation in automated machinery, they are an indispensable part of modern industry.

Understanding the different encoder types, such as incremental, absolute, linear, rotary, and optical, enables an individual to select the right technology for their specific application. As automation advances, encoders will continue to evolve, becoming smarter, more compact, and increasingly integrated with digital control systems.