PWM Control in BLDC Drivers - Theory and Practical Implemention

PWM Control is a key technique used in Brushless DC (BLDC) motor drivers to control motor speed, torque, and efficiency. It works by switching the voltage between the ON and OFF states at a high frequency within each cycle.

Brushless DC motors (BLDC motors) have become an essential component in industries requiring high efficiency, precise control and compact design. From electric vehicles and robotics to industrial automation and drones, BLDC motors are widely adopted.

At the core of BLDC motor operation it is Pulse Width Modulation (PWM), which allows for smooth speed and torque control. In this blog, we will explore the theory behind the PWM technique, how it is implemented in BLDC drivers and its benefits.

What is PWM (Pulse Width Modulation) Technique?

PWM (Pulse Width Modulation) is a widely used technique for controlling the power delivered to electrical devices, especially electric motors. It works by rapidly switching the voltage between the ON and OFF states at a high frequency.

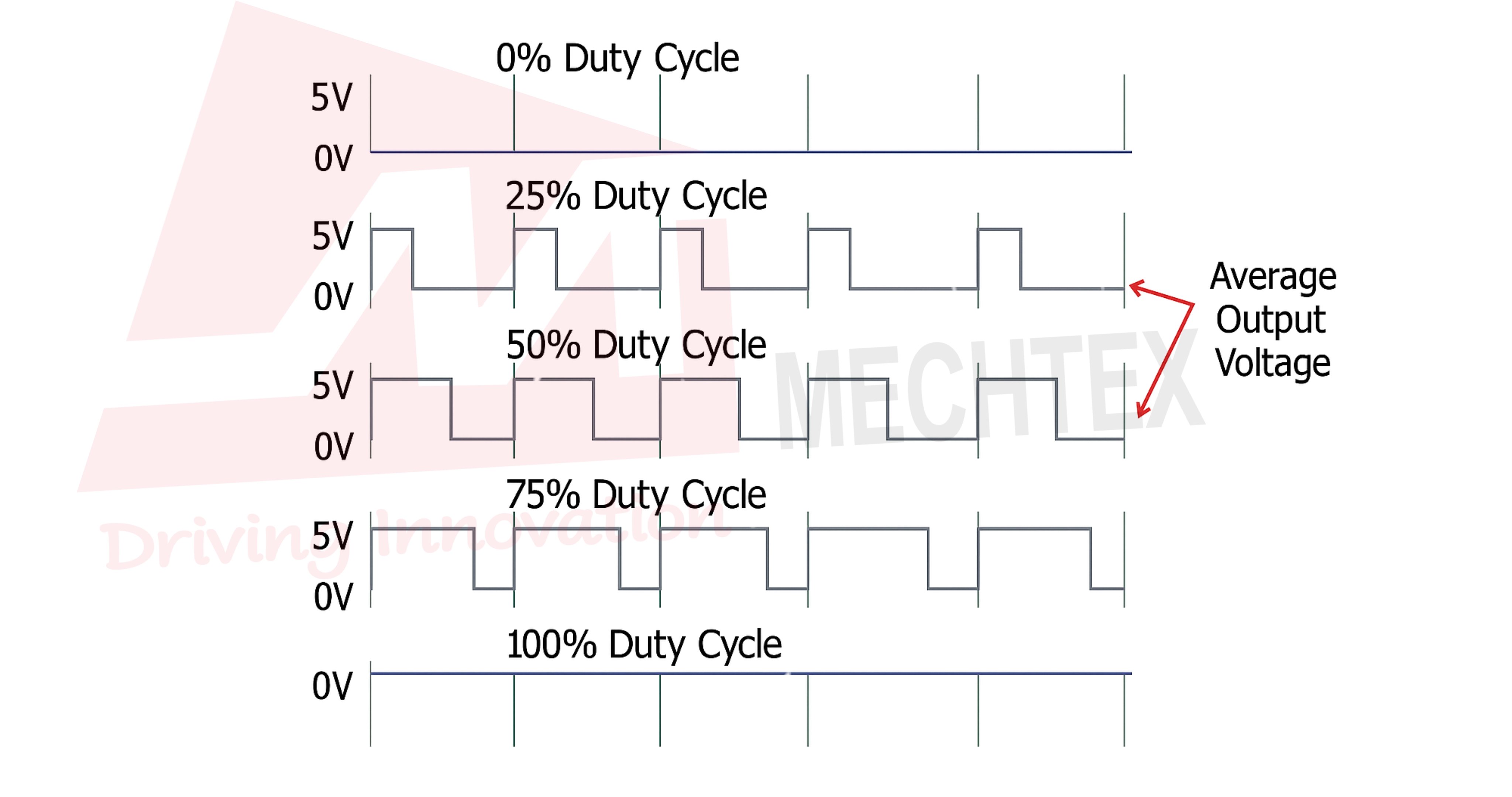

Instead of varying the voltage level continuously, PWM varies the proportion of time the signal stays ON versus OFF within each cycle. This concept is known as the duty cycle.

The duty cycle is the percentage that represents the ratio of ON time to the total period.

Duty Cycle (%) = TON / TON + TOFF x 100

- A 100% duty cycle means the signal is always ON, delivering full power.

- A 0% duty cycle means the signal is always OFF, delivering no power.

- A 50% duty cycle means the signal is ON for half the time, delivering half the maximum average voltage.

By adjusting the duty cycle, PWM allows precise control over the average voltage and current supplied to the motor. This directly influences the speed and torque of the motor.

PWM technique (Pulse Width Modulation) is especially used in BLDC motors and stepper motors where accurate speed, position and torque control is essential.

In summary, PWM provides an efficient, reliable, and finely tunable method for controlling motor performance across various applications.

Why PWM (Pulse Width Modulation) Technique Used in BLDC Drivers?

BLDC motors operate on a DC supply but require alternating current like commutation due to their electronic construction. The rotor has a permanent magnet, while the stator has windings that are energised in a specific sequence.

A BLDC driver handles this commutation and regulates power using PWM signals. PWM is the backbone of BLDC motor electronics. Some of the key reasons for using the PWM technique in BLDC drivers are:

- Precise Speed Control

BLDC motors operate on a rotating magnetic field generated by the stator winding. By adjusting the PWM duty cycle, the effective voltage across the windings changes, which directly influences the speed.

- Efficient Power Usage

PWM minimises energy losses by using digital switching as opposed to linear control, where resistive elements dissipate heat.

- Torque Regulation

Torque in the BLDC motor is proportional to the current. By modulating current via PWM signals, BLDC drivers maintain consistent torque as needed by the load.

- Smooth Operation

PWM enables smooth acceleration and deceleration by gradually changing the duty cycle to reduce the mechanical stress and improve operational life.

Implementation of PWM in BLDC Drivers

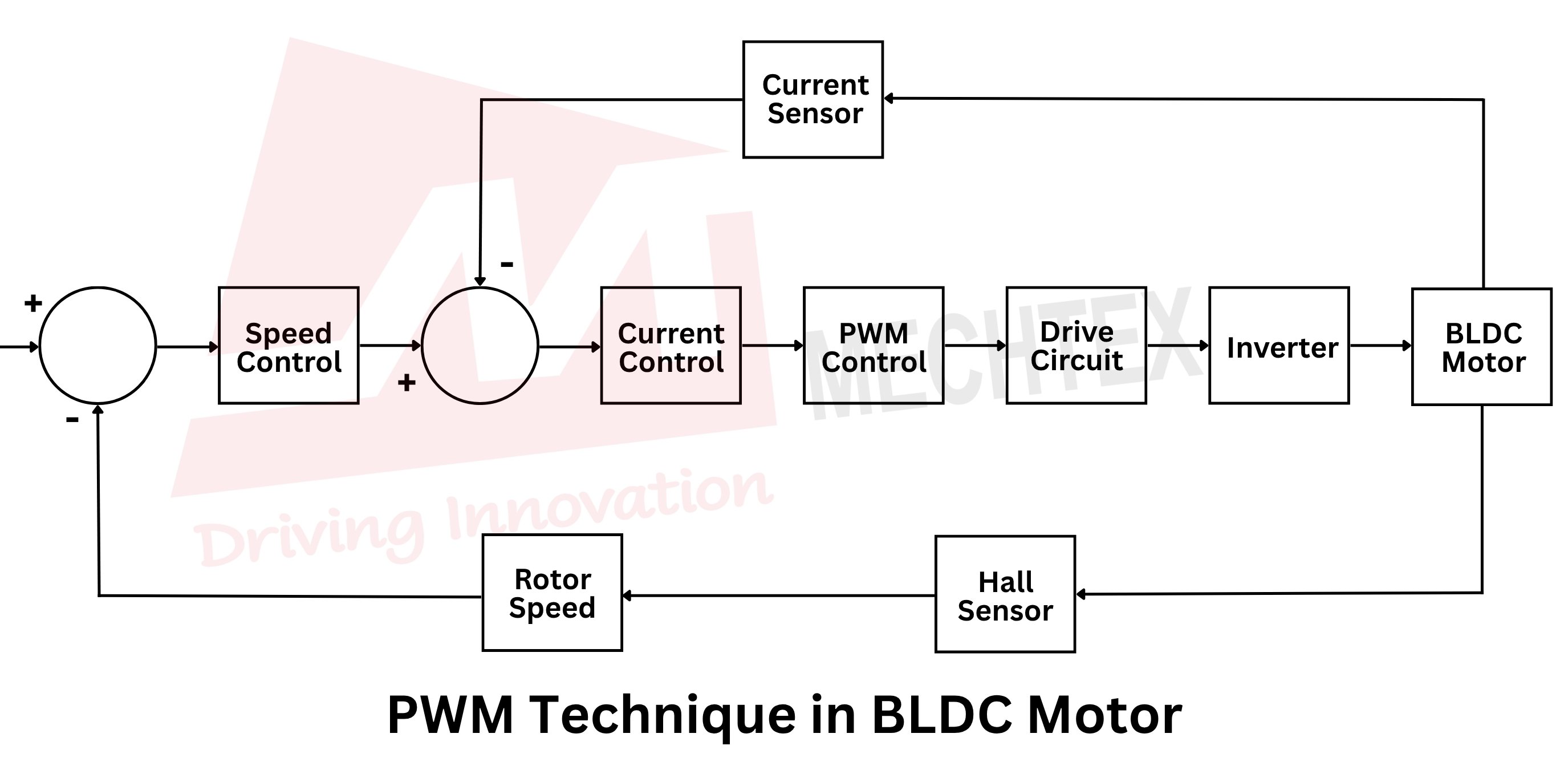

Pulse Width Modulation (PWM) is a key technique used in Brushless DC (BLDC) motor drivers to control motor speed, torque, and efficiency. Here is the step-by-step implementation of PWM in the BLDC driver:

- Define Control Objectives

Determine the desired speed, torque and direction of the motor. Accordingly, select the control method: Trapezoidal or Field-Oriented Control (FOC).

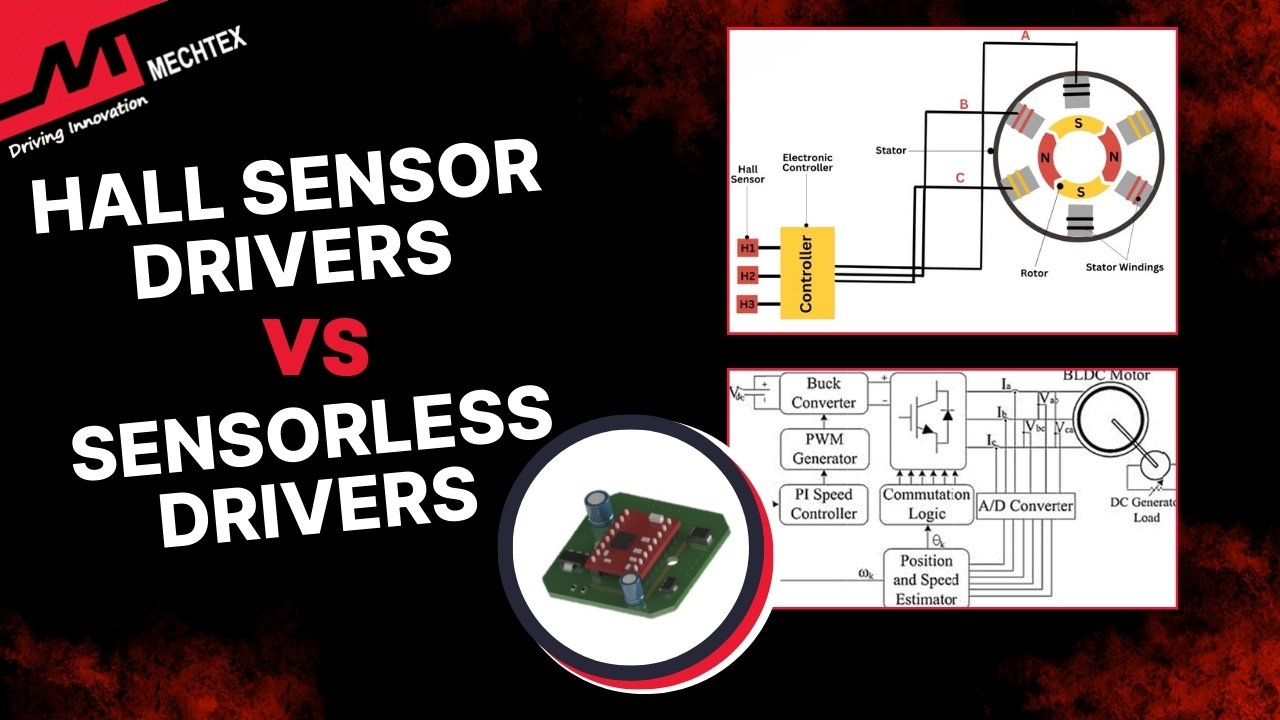

- Rotor Position Detection

Install the Hall effect sensor or use sensorless technique, such as back-EMF, to detect the rotor position to determine the correct phase commutation sequence.

- Generate PWM Signals

Use microcontrollers or motor driver IC to generate PWM signals. Select the switching frequency, such as 10 kHz and 25 kHz, which vary the duty cycle to control the average voltage and speed of the motor.

- Commutation Logic

Implement a six-step sequence for trapezoidal control or sinusoidal modulation for the field-oriented control to detect rotor position. Based on rotor position, activate specific MOSFETs in the inverter bridge.

- Driver Circuit Configuration

Use a three-phase inverter with six power transistors to ensure each transistor is capable of handling PWM switching, and add gate drivers for fast and reliable switching.

- Feedback and Control Loop

Measure the speed, voltage and current and implement PI or PID control algorithms to adjust the PWM duty cycle in real-time to ensure the motor maintains the desired speed under varying loads.

- Testing and Optimisation

Test for correct commutation and speed control to ensure fine-tune PWM frequency, duty cycle range, and control loop parameters.

Advantages of PWM Control in BLDC Drivers

- Smooth Speed Control

PWM enables fine control of motor speed without mechanical adjustments.

- High Efficiency

PWM switching results in minimal power loss compared to linear voltage regulators.

- Reduced Heat Generation

Efficient switching reduces power dissipation and improves thermal management.

- Precise Torque Regulation

Combining PWM with feedback systems allows accurate torque delivery even under varying load conditions.

- Integration with Digital Systems

PWM is easily implemented using microcontrollers, allowing for compact programmable BLDC drivers.

Conclusion

PWM (Pulse Width Modulation) control is a fundamental technique for driving BLDC motors with high efficiency and precision. By adjusting the duty cycle of PWM signals, the average voltage applied to motor windings is controlled, enabling dynamic speed and torque regulation.

Whether using trapezoidal or sinusoidal commutation, PWM serves as the backbone for modern BLDC motor drivers. Its compatibility with digital systems and excellent power-handling capabilities make it indispensable across a wide range of industries.

As BLDC applications continue to grow, mastering PWM control will be key to designing high-performance, energy-efficient motor systems.