What is a BLDC Driver| Introduction, Types and Applications

A BLDC motor driver is an essential component in the operation of BLDC motors and offers precise control over speed, torque, and direction. From industrial automation to electric vehicles, and HVAC systems to consumer electronics and medical devices, BLDC drivers offer efficient and reliable motor control solutions.

What is a BLDC Motor Driver?

A BLDC motor driver is an essential component in the operation of BLDC motors and offers precise control over speed, torque, and direction. Unlike brushed DC motors, BLDC motors do not depend upon physical brushes and commutators to transfer electrical power to motor windings. They use electronic commutation which makes them more reliable, efficient, and low maintenance.

A BLDC motor driver consists of a power stage and a control stage. The power stage includes power switches such as MOSFETs or IGBTs that operate the motor windings. The control stage consists of microcontrollers and hardware that generate proper commutation sequences based on motor position and speed.

The BLDC motor driver monitors motor position using sensors such as Hall effect sensors and adjusts commutation timing accordingly. Additionally, BLDC motor drivers incorporate features such as speed control, torque control, and fault protection to enhance the efficiency and reliability of the motors.

By precisely controlling the motor commutation, the BLDC drivers enable the motors to operate smoothly and efficiently. It optimises the motor torque and speed and allows precise control in various applications. The driver also consists of an in-built protection feature to protect the motor from overcurrent, overvoltage, and other faults ensuring the safe and reliable operation of the motor.

BLDC motor drivers are the intermediary between the motor and the application. It converts the commands into precise electrical signals and drives the motor. Its design and functionality are tailored to meet the specific requirements of applications such as industrial automation, robotics, electric vehicles, and consumer electronics for smooth and efficient operation.

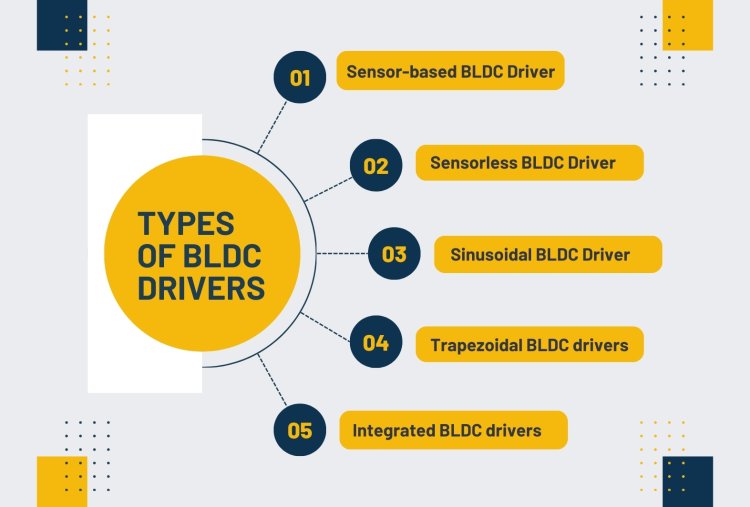

Types of BLDC Motor Drivers

BLDC (Brushless DC) motor drivers come in various types and sizes. Each type of BLDC driver is tailored to specific applications and performance requirements.

Here are some common types of BLDC drivers:

- Sensor-based BLDC Driver

Sensor-based BLDC drivers are essential for applications that require precise control over the speed and position of the motor.

These drivers use feedback from sensors such as Hall effect sensors or encoders to accurately determine the rotor position. This information enables drivers to perform the proper commutation of the motor phase and ensure optimal interaction between the stator and rotor. Therefore, these drivers offer superior performance in terms of speed regulation, torque reduction, and position accuracy.

They are well-suited for applications such as robotics, industrial automation, and medical devices, where precise control and reliability are required.

- Sensorless BLDC Driver

Sensorless BLDC drivers enable precise control over the speed and position of the motor without the need for external position sensors such as Hall effect sensors.

These drivers use techniques such as back electromotive force (EMF) sensing or other algorithms to estimate the rotor's position. By analyzing the EMF signals based on the motor and system, sensorless drivers accurately determine the position of the rotor and adjust the commutation accurately. This approach eliminates the cost and complexity of the sensor-based driver and makes these drivers cost-effective.

These drivers are suitable for applications where cost and size are constraints such as consumer electronics, automotive systems, and industrial automation.

- Sinusoidal BLDC Driver

Sinusoidal BLDC drivers produce sinusoidal current in motor windings and offer an advantage in applications where low noise and vibration are required. Unlike other drivers, which generate torque in steps, sinusoidal BLDC drivers provide smooth torque delivery throughout the motor rotation and result in less torque ripple and smooth operation. By providing smoother torque it reduces mechanical stress on components and ensures precise motion control.

These make Sinusoidal BLDC drivers suitable for applications such as electric vehicles, drones, and medical equipment where a balance of smooth operation, and reduced noise and vibration is required.

- Trapezoidal BLDC drivers

Trapezoidal BLDC drivers are known for their simplicity, reliability, and cost-effectiveness in various applications. Trapezoidal BLDC drivers offer trapezoidal current in motors winding through a straightforward commutation method. Their straightforward design makes them robust and offers reliable performance even in challenging conditions. Additionally, their ease of installation and compatibility with the motor control system offer a perfect balance of performance, reliability, and affordability.

This makes trapezoidal BLDC drivers a popular choice for a wide range of industrial and consumer applications such as where consistent and reliable motor operation is a concern.

- Integrated BLDC drivers

Integrated BLDC drivers consolidate all the critical components into a single, compact package. It integrates driver circuitry, power MOSFETs, current sensing capabilities, and protection features and offers a comprehensive solution.

Additionally, integrating all components into a single board reduces the material cost and simplifies the assembly process.

Furthermore, the reduction in external components enhances the system's reliability contributes to the longevity and performance of the motor control system, and makes them the preferred choice for applications where space is constrained.

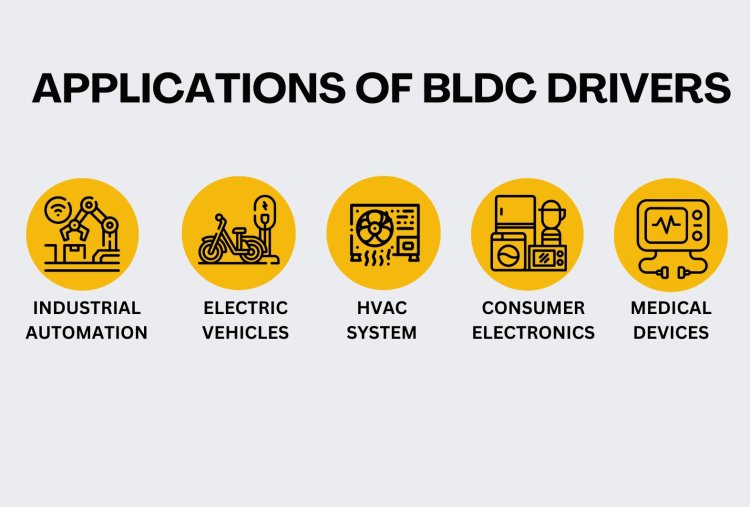

Applications of BLDC Motor Drivers

BLDC (Brushless DC) drivers find applications across various industries and sectors where precise control over motor speed, torque, and position is essential.

Some common applications of BLDC drivers include:

- Industrial Automation

BLDC drivers are extensively used in industrial automation for controlling conveyor systems, robotic arms, CNC machines, and packaging equipment. Their precise speed and position control ability ensure efficient and smooth operation in the manufacturing and assembly process.

- Electric Vehicles

BLDC drivers play a crucial role in electric vehicles, where these drivers control the motor system that drives the electric vehicle system. These drivers offer efficient and reliable motor control, improved performance, and energy efficiency to electric vehicles.

- HVAC System

HVAC systems use BLDC drivers in fans and blowers to regulate the airflow and maintain the optimal temperature in buildings and commercial spaces. These drivers offer energy efficiency operation and precise speed control, resulting in reduced energy consumption and quieter operation.

- Consumer Electronics

BLDC drivers are found in a wide range of consumer electronics such as computer cooling fans, hard disk drives, electric shavers, and kitchen appliances like blenders and mixers. Their compact size, energy-efficient features, and precise control make them ideal for applications that require continuous motor operation in compact size.

- Medical Devices

BLDC drivers are used in a wide range of medical devices such as infusion pumps, ventilators, centrifuges, and surgical tools. They provide precise control over the speed and position of the motor and ensure safe and reliable operation in critical healthcare applications.

Conclusion

BLDC motor drivers are pivotal components in a wide range of industrial applications by providing precise control over the speed and position of the motor. From industrial automation to electric vehicles, and HVAC systems to consumer electronics and medical devices, BLDC drivers offer efficient and reliable motor control solutions.

Whether it is the simple design and cost-effectiveness of trapezoidal drivers, smooth operation, and reduced noise level of sinusoidal drivers, or integration of various components in a single board of integrated BLDC drivers, each type of driver caters to specific needs across various sectors.

With continuous advancement in motor technology, BLDC drivers play an important role in driving the efficiency, performance, and sustainability of modern motor control systems. As the industry continues to demand efficient motor control systems, BLDC drivers will remain at the forefront by enabling smoother operations, enhanced reliability, and improved energy efficiency in a variety of applications.