What is a NEMA 17 Stepper Motor?

The NEMA 17 stepper motor is a hybrid stepper motor widely used in 3D printers, CNC machines, and robotics. It consists of a rotor made up of permanent magnet and stator with multiple coils and works on the principle of electromagnetic stepping.

In the world of precise motion control, NEMA motors are a go-to choice for automation applications. One of the most commonly used stepper motors is the NEMA 17 stepper motor.

In this blog, we will explore what an NEMA 17 stepper motor is, how it works, its applications, and tips for selecting the right NEMA 17.

What is NEMA 17 Stepper Motor?

A NEMA 17 stepper motor is a standardised size classification for stepper motors defined by the National Electrical Manufacturers Association (NEMA). The number “17” refers to the motor dimension, i.e 1.7 inches x 1.7 inches.

This sizing standard allows for compatibility across different systems and mounting brackets, making these motors highly popular.

These stepper motors are widely used in 3d printers, CNC machines, robotic arms, and medical instruments due to their compact size, high precision and repeatable motion control.

Watch the YouTube Video by "GalcoTV" to get a deep insight about NEMA Standards.

The “NEMA 17” designation only specifies its frame size of 1.7 x 1.7 inches, not its length, torque and other electrical characteristics. Multiple variants with different holding torques, current ratings, and step angles are available in the market.

Thanks to the standardisation by the National Electrical Manufacturers Association (NEMA), NEMA 17 motors are interchangeable and supported by a wide range of accessories such as motor drivers, mounts, and gearboxes.

Their balance of size, power, and availability makes NEMA 17 a central component in precision automation systems.

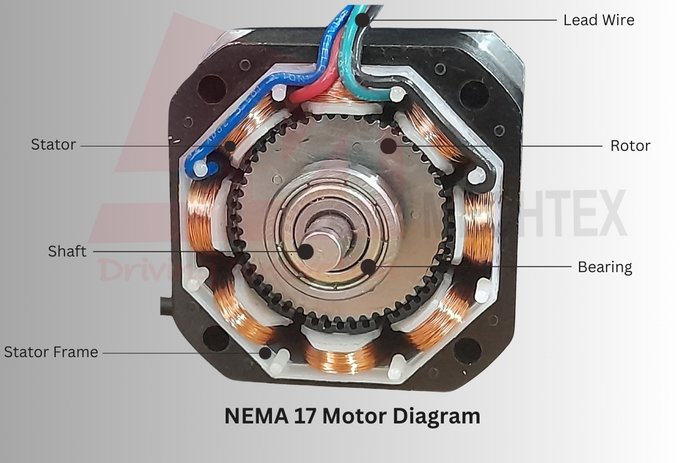

Construction of NEMA 17 Stepper Motor

The construction of the NEMA 17 stepper motor follows a typical design of a hybrid stepper motor, but adheres to the standardised frame size. Here are some important components;

- Stator

It is the stationary part of the motor. It contains multiple electromagnetic coils arranged in phases and is responsible for generating the magnetic field.

- Rotor

It is the rotating part of the NEMA 17, which consists of a permanently magnetised shaft with a toothed structure.

- Laminated Core

The stator and rotor cores are made up of stacked steel laminations to reduce eddy currents and improve efficiency.

- Bearings

High-precision ball bearings are mounted at both ends of the shaft to ensure smooth and low-friction rotation.

Working of NEMA 17 stepper Motor

The NEMA 17 stepper motor is a hybrid stepper motor widely used in 3D printers, CNC machines, and robotics.

The working of the NEMA 17 stepper motor is based on the principle of electromagnetic stepping. It consists of a rotor made up of permanent magnet and stator with multiple coils.

When electrical pulses are applied sequentially to these coils, magnetic fields are generated that pull the rotor into alignment with the energised stator pole. Each pulses result in a small, fixed angle rotation.

Precise control is achieved through a driver circuit that determines the step rate, direction, and operating mode. Microstepping divides each step into smaller increments to improve smoothness and positional accuracy. Unlike traditional DC motors, stepper motors do not require a feedback mechanism for position control.

The NEMA 17 excels in applications demanding accuracy and repeatable motion. However, it draws a constant current even at standstill and may lose torque at high speed.

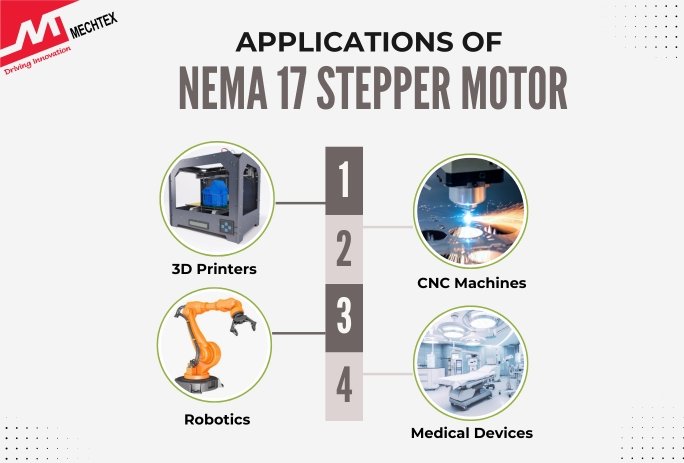

Applications of NEMA 17 Stepper Motors

NEMA stepper 17 motors are compact, high-torque motors commonly used in precise control applications due to their standard size and reliable step accuracy. Here are some common applications:

- 3D Printers

Widely used in 3D printers to control the movement of the print head and build platform. Their ability to provide precise step control ensures accurate layer deposition, contributing to the high-resolution printing.

- CNC Machines

In CNC machines, NEMA 17 are employed to drive a linear motion system such as lead screws, and timing belts. They are especially suitable for small-scale CNC routers, mills, and engravers where compact size and fine motion control are essential.

- Robotics

Ideal for robotic applications, including joint articulation in robotic arms, actuation of grippers, and driving small mobile platforms. Their precision and reliability make them a go-to choice for compact robotics applications.

- Medical Equipment

Are integrated into medical devices such as infusion pumps, blood collection machines, scanning machines and other equipment. Their compact form, quiet operation, and accurate control make them well-suited for sensitive medical devices.

Conclusion

The NEMA 17 stepper motor is a versatile and reliable component in modern motion control systems. Its standardised size, precise control, and compatibility with popular controllers make it ideal for both learning and real-world applications.

Whether you’re an engineer or industrial professional, understanding how the NEMA 17 works will give you a solid foundation in electromechanical systems.