BLDC vs. DC Motors | The Top 5 Advantages of Each

A BLDC motor is a brushless DC electric motor which operates using direct current, known for smooth operation, high efficiency and long life span, whereas DC motors are traditional brushed DC motors which rely on brushes and commutators to change the direction of current within the motor.

The debate between Brushless DC (BLDC) motors and traditional Direct Current (DC) motors is one laden with technical nuances and considerations. In a world keen on clean energy and precision, the BLDC motor has emerged as a prominent choice. Yet, underestimating the humble DC motor's capabilities would be a mistake. This blog walks through the merits and demerits of both to deduce which might be best suited for particular applications.

BLDC Motor: A New Age Revolution

BLDC motors, also known as brushless DC electric motors, represent a significant leap in motor technology. Unlike traditional DC motors, they do not rely on brushes to alternate the direction of current within the motor — a point that becomes the foundation of many of their advantages.

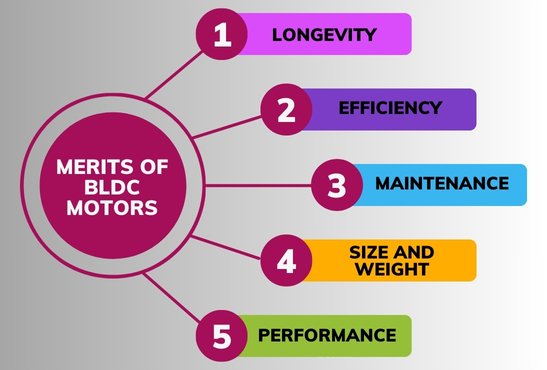

Primary Merits of BLDC Motors:

- Longevity

The absence of brushes means there is no physical contact causing wear and tear, which translates to a longer lifespan for the brushless DC motor.

- Efficiency

BLDC motors exhibit higher efficiency since they do not lose energy through friction and heat generation associated with brushes.

- Maintenance

Reduced maintenance is a significant upside; without brushes, there is no need for replacements or cleaning associated with brush degradation.

- Size and Weight

When considering a small brushless DC motor vs a DC motor of similar power rating, the former typically has a smaller footprint and is lighter, making it better for applications where space and weight are concerns.

- Performance

The performance of a BLDC motor, in terms of speed and torque, is better controlled and can be more finely tuned through electronic control.

Applications of BLDC Motors

Because of their high efficiency and power-to-size ratio, small BLDC motors are ideal for a diverse range of applications, from precision devices like drones and medical instruments to everyday household appliances and automotive components.

The Case for DC Motors

Traditional DC motors, despite seeming technologically surpassed, still hold their ground in numerous situations.

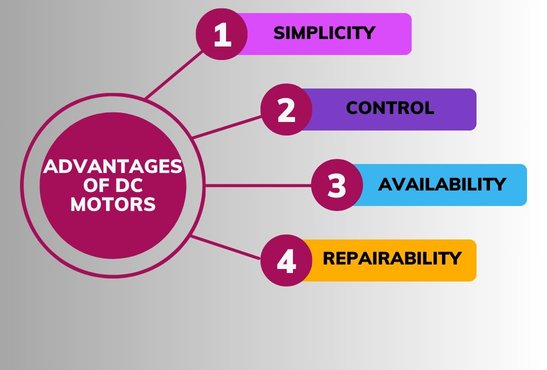

Key Advantages of DC Motors:

- Simplicity

The construction of a DC motor is straightforward, which often translates to lower initial costs and ease of understanding.

- Control

DC motors provide simple control of speed and torque, making them suitable for applications where these factors are readily adjusted based on load.

- Availability

DC motors have been around for a long time, making them readily available for a variety of uses and often at a lower price point.

As a leading DC geared motor supplier, Mechtex offers a wide range of readily available and cost-effective solutions, catering to the diverse needs of various industries that have relied on the time-tested performance and affordability of DC motor technology.

- Repairability

The simpler design means easier repair and serviceability, often being manageable without highly specialised knowledge.

Applications of DC Motors

DC motors shine in applications where robustness and cost-effectiveness are priorities, such as in heavy machinery, automotive starters, or kiddie rides, where complex speed controls are not necessary.

The Verdict: BLDC vs DC Motors

The choice between a small BLDC motor and a traditional DC motor comes down to the specific requirements of the application. For industries focused on precision, space-saving designs, and long-term cost savings through energy efficiency and reduced maintenance, the BLDC motor is superior. The small brushless DC motor, in particular, finds favour in modern gadgets and tech owing to lower noise levels and reliability.

On the other hand, in scenarios where simplicity, ease of repair, initial cost savings, and speed variability are deemed more critical, the traditional DC motor still holds relevance. It is not so much a question of which is better universally, but which is better suited for the task at hand.

Conclusion

Both BLDC motors and DC motors have their rightful place within various sectors of technology and industry. As the demand for more compact, efficient, and maintenance-free motors rises, we'll likely witness an increased prevalence of BLDC motors, especially in consumer electronics and applications where agility and precision are non-negotiable.

Yet, there will always be a niche for DC motors, perhaps in educational settings for instructional purposes or in industrial scenarios where their robust simplicity is still valued.

As we stride into the future of motor technology, it's the alignment of these technologies with user needs that will ultimately dictate their lasting power. With companies like Mechtex at the forefront of motor manufacturing, be it a small BLDC motor or a sturdy DC motor, rest assured — there's a motor out there crafted for your specific requirements.