Step Loss in Stepper Motors: Causes and How to Prevent It

Step loss in a stepper motor refers to the condition where the stepper motor fails to rotate at a step angle in response to the input pulse. It affects the performance of the stepper motor and reduces the efficiency of the applications.

Stepper motors are widely used in applications such as CNC machines, 3D printers, and industrial automation, where precision is required. Unlike other motors, stepper motors move in discrete steps and allow speed and torque control without any feedback system.

However, in the real world, the precise control over speed and torque may cause step loss in the stepper motor.

In this blog, we will explore what step loss means in a stepper motor, what the causes are, how it impacts the performance of the stepper motor and prevention methods to control step loss.

What is Step Loss in Stepper Motor?

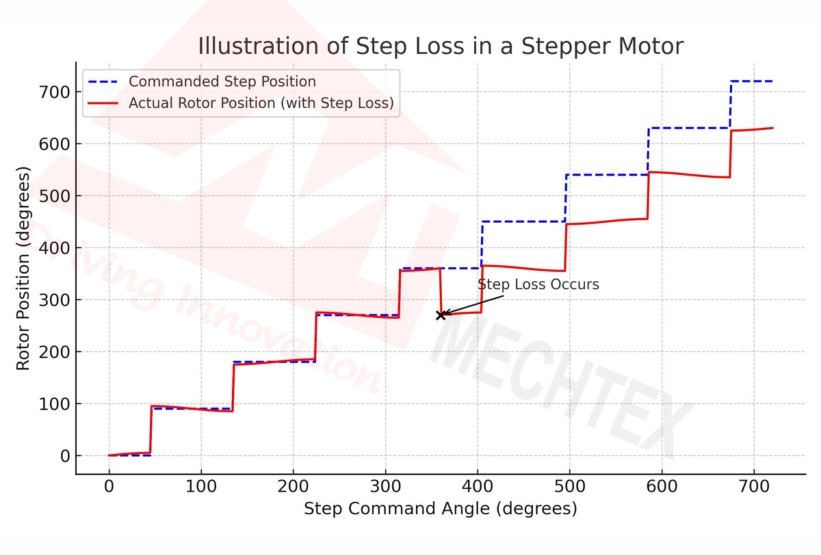

Step loss in stepper motor refers to the condition where the stepper motor fails to rotate at a step angle in response to the input pulse. In normal operation, each electrical pulse is sent to the stepper motor, corresponding to the precise angular movement, which allows it to move in discrete steps without any feedback control.

However, when step loss occurs, the rotor either lags or skips the expected position, which results in a mismatch between the estimated and actual position.

This phenomenon is significant in applications such as CNC machines, 3D printers and robotics where precise positioning is crucial.

As stepper motors operate an open-loop control system, it means their control system assumes that every pulse will result in exact motion. If a step loss happens, the control system of the stepper motor remains unaware of the loss, which leads to positional error.

Also, step loss is often transient and may occur at any point during the operation. It does not mean a stepper motor will fail at every step loss. Sometimes, a synchronisation between the electrical input and mechanical motion is disrupted and causes positional errors.

Understanding the step loss in a stepper motor is essential for engineers to understand the limitations of the stepper motor and ensure the motor operates efficiently within its boundaries.

Causes of Step Loss in Stepper Motor

Step loss in a stepper motor means the motor fails to rotate at a particular step angle, which results in loss of accuracy. This loss affects the performance of the stepper motor and reduces the efficiency of the applications.

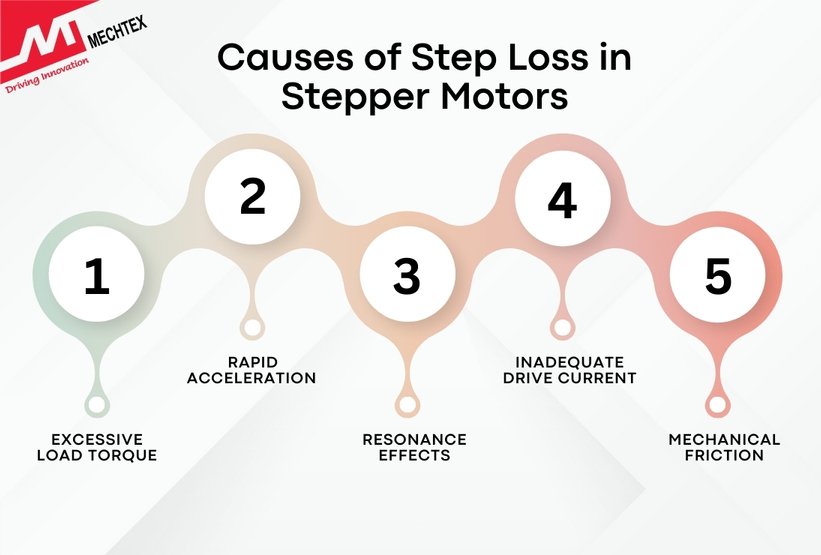

There are several factors that cause the step loss in the stepper motor and affect its performance. Some key factors are:

- Excessive Load Torque

When the load torque of the stepper motor exceeds the available torque at a given speed, the rotor cannot synchronise with the magnetic field of the stator, which results in overload.

This overload condition is common in applications which require precise positioning with sudden load change, high inertia systems and cause positional inaccuracy.

- Acceleration and Deceleration Too Fast

Every stepper motor has a torque-speed characteristic which limits its performance during rapid acceleration and deceleration. If the acceleration ramp is too steep, the rotor does not synchronise with the magnetic field and misses the steps.

- Resonance Effects

Stepper motors can experience mechanical resonance at certain speeds, especially at the natural frequency. This resonance reduces the torque output and causes instability, which leads to step loss.

- Inadequate Drive Current

In a stepper motor, if the driver does not supply enough current to the stator, the magnetic field strength of the stator is insufficient to hold or move the rotor to a specific angle. It results in a step loss.

- Mechanical Binding or Friction

Misalignments, worn bearings, can cause friction and require motor torque than the stepper motor delivers. It is the common cause of step loss in applications that require precision in motion.

Effects of Step Loss in a Stepper Motor

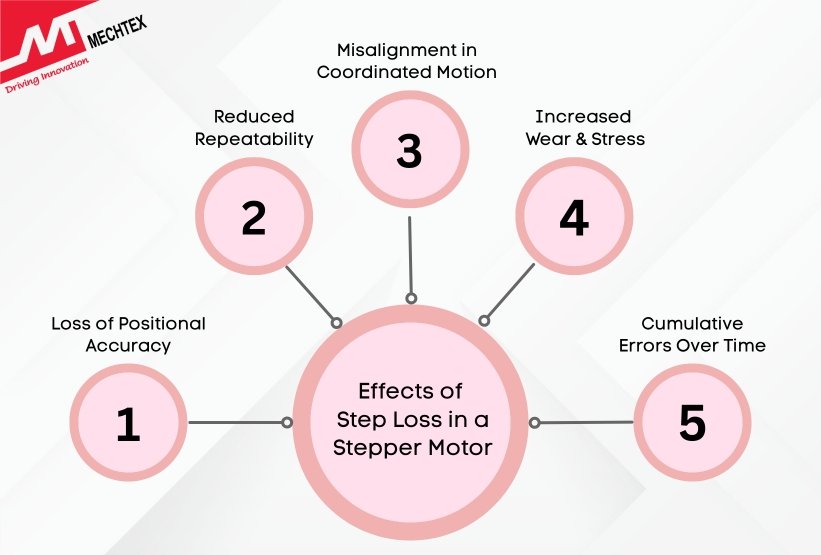

There are several effects which a stepper motor experiences due to the step loss. Some of the common effects of step loss in stepper motors are:

- Loss of Positional Accuracy

The primary effect of step loss in a stepper motor is the deviation in positions. Since the stepper motors operate in an open-loop system, they do not have a feedback system to detect the deviations and correct them.

This causes positional accuracy errors in applications such as CNC machines, 3D printers, where precise positioning is essential.

- Reduced Repeatability

In a stepper motor, when step loss occurs intermittently, the motor still reaches its target i.e. achieves its position.

But repeatability at the same position at a consistent pace decreases. In precision manufacturing applications such as robotics systems, this results in inconsistent performance and reduced efficiency.

- Misalignment in Coordinated Motion

In a multi-axis system, step loss at one axis disrupts the coordination between all axes and creates improper movements. For example, in a gantry system, missed steps on one motor can cause skewing, uneven cuts, or collisions between moving components.

- Increased Wear and Mechanical Stress

In a stepper motor, if a step loss is frequent, the system or applications may experience mechanical jerks. As the stepper motor tries to regain its position, the load encounters with motor and creates jerks.

Over time, these mechanical jerks cause wear on couplings, bearings and other mechanical components of the stepper motor.

- Cumulative Errors Over Time

Unlike servo motors, stepper motors do not have any feedback mechanism which detects errors and allows to do corrections. Therefore, if there is a repeated operation, the missed steps accumulate over time and cause large deviations in the operation.

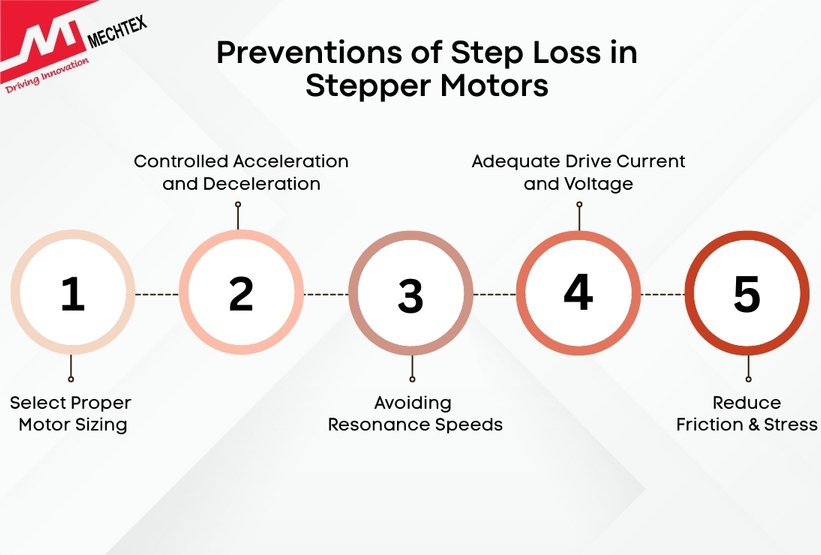

Prevention of Step Loss in Stepper Motors

Preventing step loss in a stepper motor is essential to maintain positional accuracy, system reliability, and operational reliability. Since many stepper motors do not use any feedback system for positional accuracy, avoiding any deviation, such as step loss, can be achieved using various methods.

Some of the prevention methods to avoid step loss in stepper motors are:

- Proper Motor Sizing

Selecting a stepper motor with sufficient torque to handle the load is the first line of prevention against the step loss.

One must consider both continuous and peak torque requirements, load inertia, friction and rapid acceleration and deceleration while selecting the size of the stepper motor.

- Controlled Acceleration and Deceleration

Control acceleration and deceleration in the stepper motor during the operation prevent the rotor from desynchronisation with the magnetic field of the stator.

Using trapezoidal or S-Curve methods in the controller ensures a smooth transition and reduces the step loss.

- Avoiding Resonance Speeds

In stepper motors, operating at mechanical resonance can cause torque loss and instability in performance. Using microstepping techniques or mechanical dampers can help to avoid resonance zones and improve movements.

- Adequate Drive Current and Voltage

In stepper motors, ensuring that the driver supplies sufficient current to the stator windings results in smooth rotor movement.

One must set the current limits according to the motor’s requirements. It ensures that sufficient power is supplied to the motor’s winding without any loss to deliver consistent performance.

- Reducing Mechanical Friction and Misalignment

Regular maintenance of the components of stepper motors, such as couplings, bearings, and lead screws, is essential. It will reduce unnecessary friction and provide proper alignment between the motor and driven load to avoid step loss.

Conclusion

Step loss in stepper motors is a silent but impactful issue that can compromise precision, repeatability, and efficiency in motion control applications.

By understanding the causes of step loss, from insufficient torque and over-acceleration to resonance and electrical noise, engineers can design preventive measures such as motor oversizing, microstepping, proper motion profiling, and regular maintenance.

In high-precision industries, avoiding step loss isn’t just about better motor control — it’s about ensuring product quality, system safety, and operational efficiency.