Kalman Observer & Sliding-Mode Observers in BLDC Motor

Kalman observer estimates BLDC rotor position using statistical prediction, while the Sliding-Mode observer uses nonlinear control for robust estimation. In these sensorless control methods, rotor position is detected mathematically, instead of direct measurement.

BLDC Motors are widely used in robotics, electric vehicles (EVs), and industrial automation applications due to their high efficiency, low maintenance requirements, and excellent torque-speed control capabilities. However, precise rotor position estimation is essential for the following applications for their operation.

Traditionally, the Hall effect sensor and encoders are used to detect the rotor position. However, these methods complicate the design of BLDC motors, increase costs and reduce the efficiency of the motor.

This has led to the development of advanced sensorless control techniques such as Kalman observers and Sliding-Mode observers (SMOs). In these methods, rotor position is detected mathematically, instead of direct measurement.

In this blog, we will explore how these techniques function, their advantages, challenges, and applications in BLDC motors.

Why Rotor Position Estimation Matters

Rotor position estimation is crucial in BLDC (Brushless DC) motor because its operation depends upon accurate commutation.

Unlike brushed DC motors, BLDC motors do not use mechanical brushes and commutators. They rely on electronic switching of current into stator windings, which must be synchronised with the rotor’s magnetic field.

If the rotor position of BLDC motors is not correctly estimated, the current may be applied to the wrong winding and reducing torque, increasing noise and vibration, and even causing motor stalling.

Accurate rotor position detection ensures sufficient torque production, smooth rotation, and high efficiency performance. It also directly affects the torque-speed control and efficiency of the BLDC motor.

Traditionally, Hall effect sensors and back EMF methods are used to detect the position of the rotor of the BLDC motor. However, due to some limitations, it leads engineers to develop and switch to the advanced methods such as the Kalman filter and Sliding-Mode Observers.

Therefore, estimating the rotor position is essential in a BLDC motor because it determines the efficiency and performance of the BLDC motor.

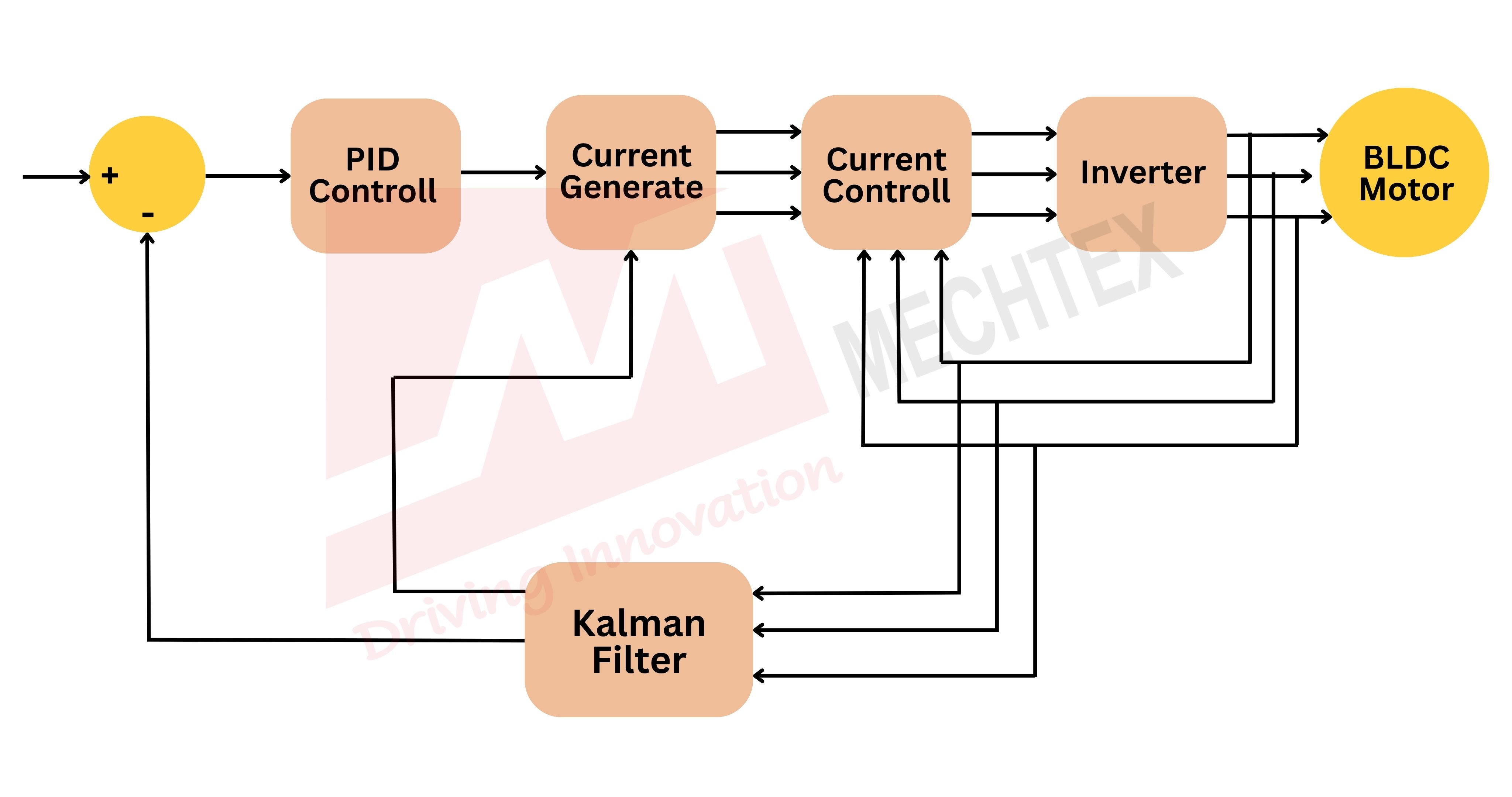

Kalman Observer for BLDC Position Estimation

In a Brushless DC motor (BLDC motor), accurate rotor position detection is essential for proper commutation and smooth operation.

Traditionally, Hall effect sensors or encoders are used to provide direct feedback about rotor position. However, they add complexity and do not offer reliable information about rotor position.

To overcome these methods, engineers have developed advanced sensorless techniques which detect the rotor position from measurable electrical quantities.

Among all methods, the Kalman Observer or Kalman Filter has emerged as the most reliable method due to its ability to handle noisy signals, model uncertainties, and system variations.

The Kalman Observer technique combines a mathematical model of the BLDC motor with real-time measurement to deliver refined and accurate rotor position.

Working of Kalman Observer

The Kalman Observer or Kalman Filter technique operates at two stages: prediction and correction.

- Prediction Stage

In this stage, the Kalman Observer technique uses the BLDC motors mathematical space-state model, where the observer predicts the next rotor position based on inputs such as applied voltage and current.

This prediction about rotor position is subject to BLDC motor model inaccuracies and external disturbances.

- Correction Stage

In this stage, real-time measurements such as phase currents and voltages are compared with predicted values.

Then, Kalman gains the adaptive weighing factors and determines how much the estimations should be corrected for accurate rotor position information.

With the help of prediction and correction cycles, the observer filters out the noisy signals and dynamically adjusts the disturbance to provide accurate and stable rotor position information.

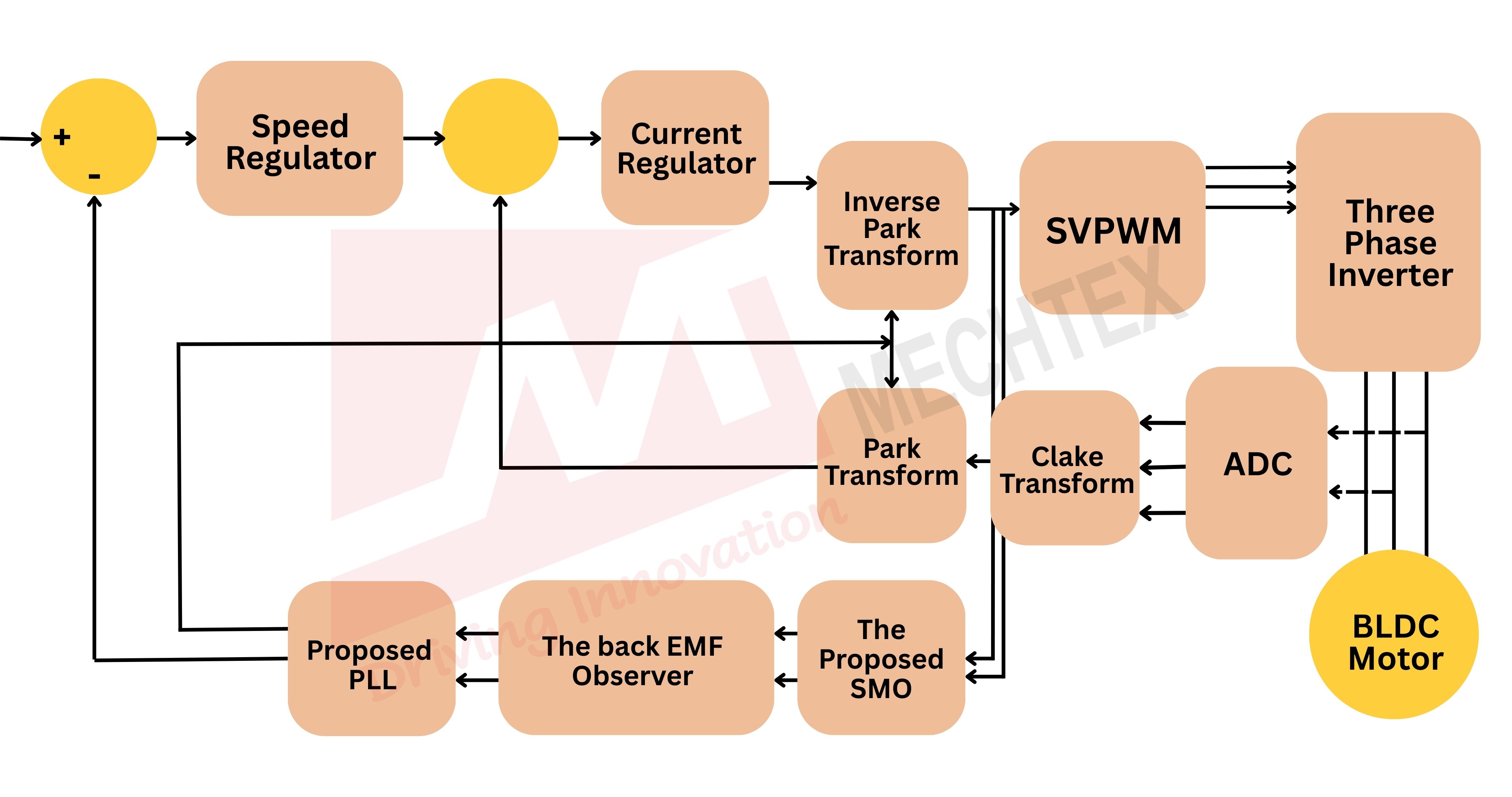

Sliding-Mode Observer for BLDC Position Estimation

In Brushless DC (BLDC) motor, detecting rotor position is essential for precise electronic commutation.

Among various advanced sensorless methods to estimate rotor position, the Sliding-Mode Observer technique is the most prominent technique due to its robustness against parameter variations, external disturbances, and system inaccuracies.

Unlike traditional observers, which rely on an accurate motor model. Sliding-Mode Observer leverages the principle of non-linear control and variable structure systems.

These features make the Sliding-Mode Observer method an effective technique to detect the rotor position, especially in noisy environment and harsh conditions.

Working of Sliding-Mode Observer

The Sliding-Mode Observer technique works by transforming the BLDC motor’s dynamic equations into the non-linear state representation. This technique introduces a sliding surface, which is used to define the error between the predicted value and the measurable value.

The observer drives the error towards zero by applying a discontinuous switching function, which forces the system to “slide” along with defined surface.

The Sliding-Mode Observer technique operates at three stages: Prediction, Switching Mechanism, and Position Estimation.

- Prediction Setup

In this stage, the observer predicts the motor states, such as current, based on applied voltages and estimated position.

- Switching Mechanism

In this stage, A nonlinear control law introduces a switching signal to ensure that deviation from the sliding surface is corrected quickly.

- Position Estimation

In this stage, once the back-EMF components are accurately reconstructed with the help of sliding dynamics, the rotor position and speed are estimated properly.

By continuously applying the sliding condition, the Slide-Mode Observer technique achieves robustness and stability even with mismatched parameters.

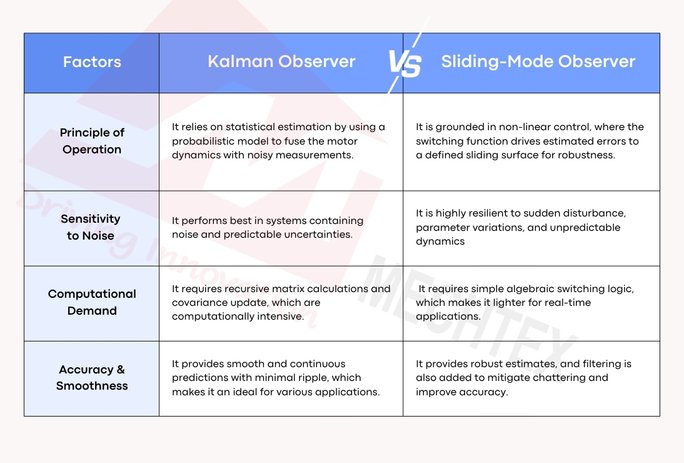

Kalman Observer vs Sliding-Mode Observer in BLDC Position Estimation

- Principle of Operation

- Kalman Observer: This technique relies on statistical estimation by using a probabilistic model to effectively fuse the motor dynamics with noisy measurements.

-

- Sliding-Observer: This technique is grounded in non-linear control, where switching function drives estimated errors to a defined sliding surface for robustness.

- Sensitivity to Noise and Disturbances

-

- Kalman Observer: This method performs best in systems containing noise and predictable uncertainties. But they must degrade if the noise characteristic changes.

-

- Sliding-Observer: This method is highly resilient to sudden disturbance, parameter variations, and unpredictable dynamics, though switching can be introduced through chattering.

- Computational Demand

- Kalman Observer: Kalman requires recursive matrix calculations and covariance update, which are computationally intensive.

-

- Sliding-Observer: Sliding-Observer require simple algebraic switching logic, which makes it lighter for real-time applications with low-cost controllers.

- Accuracy and Smoothness

- Kalman Observer: It provides smooth and continuous predictions with minimal ripple, which makes it an ideal technique for applications where precision is critical.

-

- Sliding-Observer: It provides robust estimates, and filtering is also added to mitigate chattering and improve accuracy.

- Application Suitability

- Kalman Observer: This technique is better for high-performance systems and robotics with well-defined noise statistics.

-

- Sliding-Observer: This technique is suited for applications that operate in rugged environments such as automotive, aerospace and industrial drives where robustness is required.

Conclusion

Rotor position estimation is at the heart of sensorless BLDC motor control. While traditional methods like back-EMF sensing serve well in specific conditions, advanced observers such as Kalman filters and Sliding-Mode observers push performance further, especially in demanding environments.

- Kalman Observers offer optimal accuracy and noise rejection, but at higher computational costs.

- Sliding-Observer provides robustness and efficiency, making it attractive for cost-sensitive and embedded applications.

As industries continue pushing for higher efficiency, compactness, and reliability, these advanced observers will play a central role in shaping the next generation of BLDC motor control systems.

By mastering these techniques, engineers can design sensorless BLDC drives that deliver unmatched performance across automotive, aerospace, and industrial sectors.