Hunting in Synchronous Motor

Hunting in synchronous motors is the phenomenon that describes the oscillatory behaviour of the rotor to maintain its synchronisation with the rotating magnetic field (RMF) of the stator. It can adversely affect the performance of the motor by causing instability, energy losses, reduced efficiency and challenges in controlling the speed of the synchronous motor.

What is a Synchronous Motor?

A synchronous motor is an AC motor that operates at a synchronised speed with the frequency of the current supply. Unlike induction motors, which experience a slip and operate slightly below synchronous speed. A synchronous motor runs at a constant speed regardless of any load. This makes synchronous motors highly reliable for tasks where constant speed is crucial.

A synchronous motor consists of two main components: stator and rotor. A stator is the stationary part of the motor and consists of winding that produces a rotating magnetic field (RMF) when energised by the power supply. The rotor is the rotating part of the motor. It is either a salient pole or cylindrical shape equipped with permanent magnets. When current is supplied to the permanent magnet, it creates a magnetic field.

Watch the YouTube Video by "Lesics" to learn about the Working of Synchronous Motor

The working principle of a synchronous motor is based on the interaction between the stator’s rotating magnetic field and the rotor. The stator is energised with the AC supply, it produces a rotating magnetic field determined by the frequency of supply and number of poles. This rotating magnetic field interacts with the permanent magnets of the rotor and causes the rotor to rotate at the same speed as the stator’s magnetic field. It is known as synchronous speed.

The formula to calculate the synchronous speed of a synchronous motor is as follows:

Ns = 120xƒ/P

where,

ƒ is the frequency of supply and P is the number of poles of the motor.

Also Read

Working Principle of Synchronous Motor

Synchronous motors are commonly used in applications that demand constant speed and high precision, such as in clocks, timers, conveyor systems, and various industrial machines. They are also employed in power factor correction, as they can operate at a leading or unity power factor, thus improving the efficiency of the electrical grid.

What is Hunting in a Synchronous Motor?

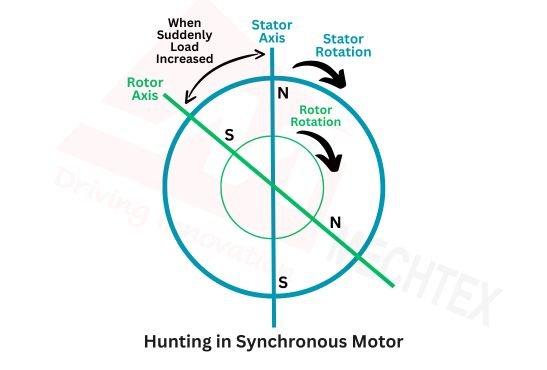

Hunting in synchronous motors is an important phenomenon that describes the oscillatory behaviour of the rotor to maintain its synchronisation with the rotating magnetic field (RMF) of the stator. A synchronous motor is designed to run at a constant speed determined by the frequency of supply. The rotor must match the speed of the stator's rotating magnetic field to maintain its synchronous speed.

When there is a sudden change in the load of the synchronous motor, for example, if something is suddenly connected to the motor, the motor becomes heavier or lighter. Due to a change in load, the rotor might temporarily fall behind or speed up to match the magnetic field of the stator.

For instance, if the load increases suddenly, the rotor may lag behind. If the load decreases suddenly, the rotor may move ahead of the stator’s magnetic field. This creates a mismatch between the rotor’s speed and the stator’s magnetic field.

To correct this mismatch, the rotor starts to oscillate around the ideal speed of the stator. This oscillation continues until the rotor realigns with the rotating magnetic field (RMF) of the stator and returns to its constant speed. This process is known as hunting in synchronous motors. This process shows how the synchronous motor tries to maintain its synchronous speed when there is a change in load unexpectedly.

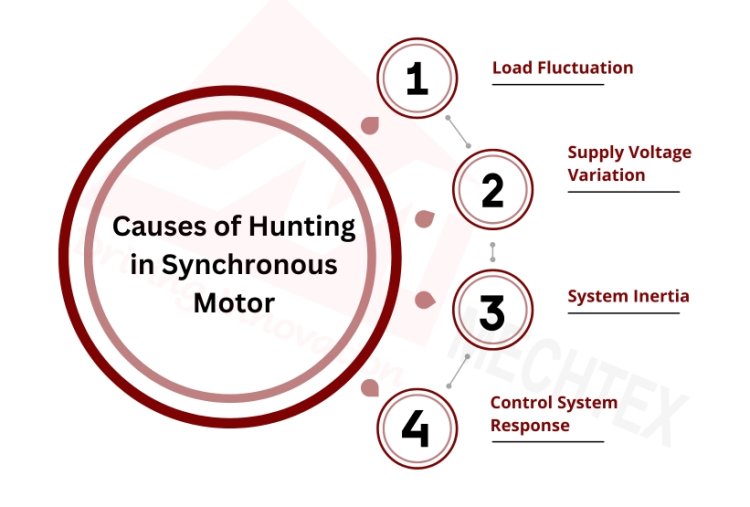

Causes of Hunting in Synchronous Motor

Hunting in synchronous motors can be caused by several factors. Each factor disrupted the balance between the rotor and the rotating magnetic field of the stator. Here are some main causes of hunting in synchronous motors:

- Load Fluctuation

Sudden change in load, such as an increase or decrease in mechanical load, causes the rotor to lag or speed up from its synchronous speed. The rotor’s temporary lag or speed-up leads to oscillation that realigns with its synchronous speed.

- Supply Voltage Variation

Fluctuation in the voltage supplied to the synchronous motor can affect the strength of the magnetic field of the stator. Changes in the strength of the magnetic field of the stator can disturb the rotor’s alignment with the magnetic field and create a mismatch with the stator’s magnetic field.

- System Inertia

If the synchronous motor has high inertia, it can affect the feedback ability of the motor. For instance, high inertia can affect the motor’s ability to adjust to load changes and cause temporary lag or speed-up in the rotor’s behaviour.

- Control System Response

Inadequate or slow response from the motor control system can lead to hunting. If the motor control system cannot quickly respond to the change in load and correct the deviation in the rotor’s speed. The rotor creates a mismatch with the stator’s magnetic field and causes hunting.

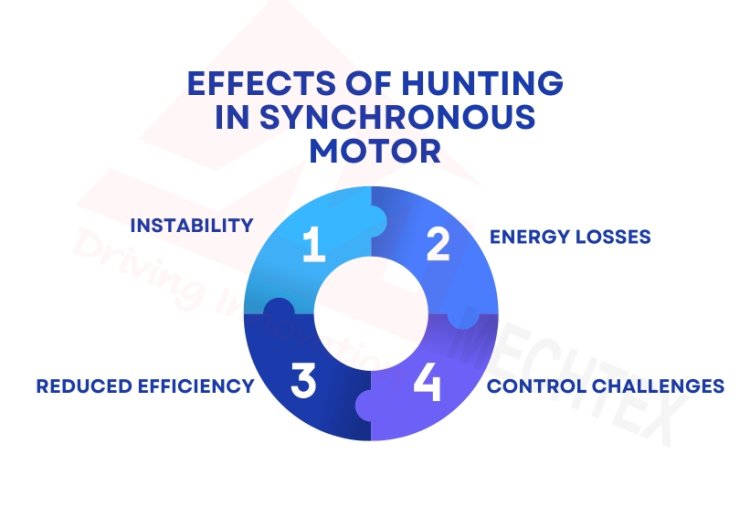

Effects of Hunting in Synchronous Motor

Hunting in the synchronous motor may have several adverse effects on the synchronous motor. This effect impacts both the motor’s performance and its overall system. Here are some key effects of hunting in synchronous motor:

- Instability

Continuous hunting in a synchronous motor can lead to instability in its operation. The rotor’s oscillations around the synchronous speed can cause fluctuation in the speed and torque of the motor and lead to insatiable performance.

- Energy Losses

The oscillatory movement of the rotor caused by the hunting results in additional energy losses. It is due to the rotor’s continuous adjustments with changes in load to match the synchronous speed and requires extra power.

- Reduced Efficiency

As the synchronous motor hunts continuously, it affects its overall efficiency. The constant oscillation of the rotor to match its actual speed results in high energy loss and decreases the overall efficiency of the motor.

- Control Challenges

Applications that require precise speed control may affect the hunting in synchronous motors. Hunting can complicate the control system and make it difficult to maintain constant speed and position, which affects the operation of applications that require high-speed control.

Preventions for Hunting in Synchronous Motor

Preventions for hunting in synchronous motors involve several strategies that aim to stabilise the rotor and maintain its synchronisation with the stator’s magnetic field. Here are some measures for preventing hunting in synchronous motors:

- Damping System

A damping system involves the installation of damper winding or electromagnetic dampers. Damper windings, also known as amortisseur windings, are the additional windings placed into the rotor. These windings help the rotor to absorb or dissipate oscillatory energy and reduce the hunting.

- Voltage Regulation

Maintaining a stable supply of voltage using a voltage regulator or automatic voltage controller helps to keep the magnetic field strength steady and reduces the chances of hunting.

- Improved Control System

Use an advanced control system that can respond quickly to the deviation between the rotor’s speed and the stator's magnetic field. Modern digital controllers with feedback mechanisms can provide precise adjustments and help to stabilise the rotor with the stator's magnetic field and reduce hunting.

- Regular Maintenance

Perform regular maintenance of the synchronous motor to ensure all the components of the synchronous motor are functioning properly. Addressing wear and tear and making necessary adjustments can help to prevent hunting.

Conclusion

Hunting in synchronous motors represents a complex behaviour where the rotor oscillates around the synchronous speed due to variations in load. This phenomenon can adversely affect motor performance by causing instability, energy losses, reduced efficiency and challenges in controlling the speed of the motor. Addressing hunting using various measures, such as using the damping system, voltage regulation, and regular maintenance, can minimise the impact of hunting, leading to more stable, efficient, and reliable operation of synchronous motors.