Noise Reduction Techniques in BLDC Motors

A BLDC motor is a type of electric motor that operates without brushes, unlike traditional brushed DC motors. Understanding the various sources of noise in BLDC motors is crucial for enhancing their performance, especially in noise-sensitive applications such as medical devices, robotics, and HVAC systems.

BLDC motors have become the preferred choice in many industries due to their high efficiency, compact size, and long operational life. However, like all electric motors, BLDC motors are not immune to noise.

In applications like HVAC systems, electric vehicles, and medical devices, noise and vibration from BLDC motors can become a critical concern, affecting comfort, precision, and longevity.

What is a BLDC Motor?

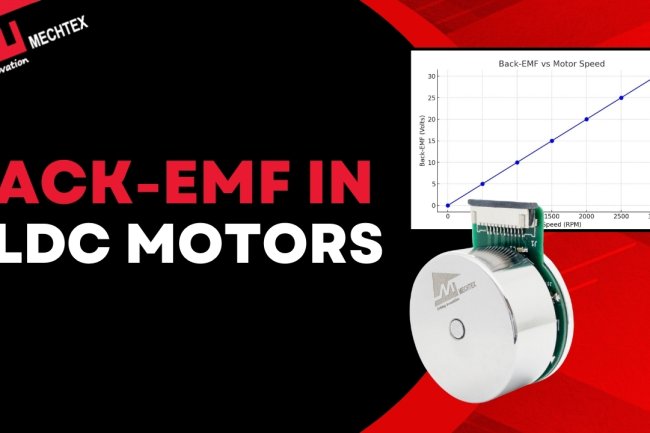

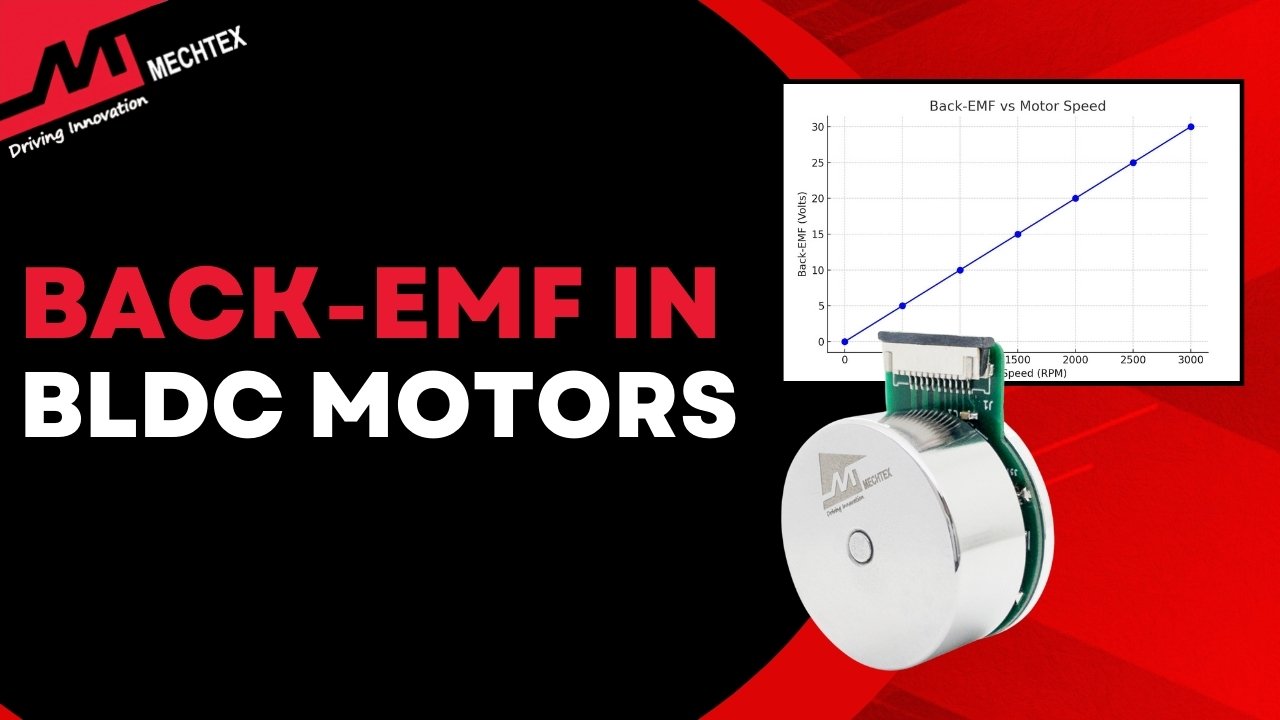

A BLDC motor is a type of electric motor that operates without brushes, unlike traditional brushed DC motors. Instead of mechanical commutation, BLDC motors use electronic commutation through a controller which switches the current in the motor windings based on feedback from hall sensors and back EMF.

Construction of BLDC motors consists of two main components: stator and rotor. The stator is the stationary part of the motor, made up of laminated steel and copper windings. Rotor is the rotating part of the BLDC motor embedded with permanent magnets.

When stator windings are energised in a specific sequence, they create a rotating magnetic field that interacts with the rotor magnets, causing the rotor to spin.

BLDC motors require an electronic speed controller (ESC) to manage commutation and performance. Some brushless DC motors use Hall effect sensors for position detection, while others use sensorless control algorithms based on back-EMF.

BLDC motors are known for their high efficiency, precise speed, and low maintenance due to the absence of brushes. They also offer a better torque-to-weight ratio and can operate at high speeds. These characteristics make BLDC motors ideal for applications in electric vehicles, drones, robotics, HVAC systems, medical devices, and consumer electronics.

Also Read

What is a BLDC Motor| Construction, Working and Applications

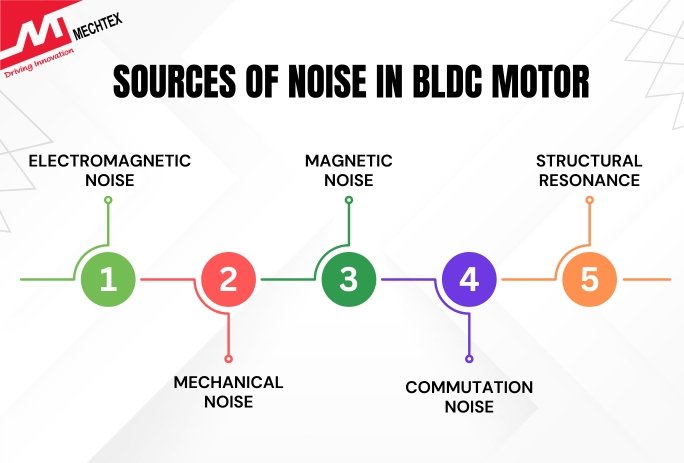

Sources of Noise in BLDC Motors

BLDC motors, also known as brushless DC motors, are valued for their high efficiency, compact design and low maintenance. However, they generate noise during operation.

Understanding the various sources of noise in BLDC motors is crucial for enhancing their performance, especially in noise-sensitive applications such as medical devices, robotics, and HVAC systems.

- Electromagnetic Noise

Electromagnetic noise is one of the most common types of sources in BLDC motors. It is primarily caused by the switching of current at high frequency in the stator winding.

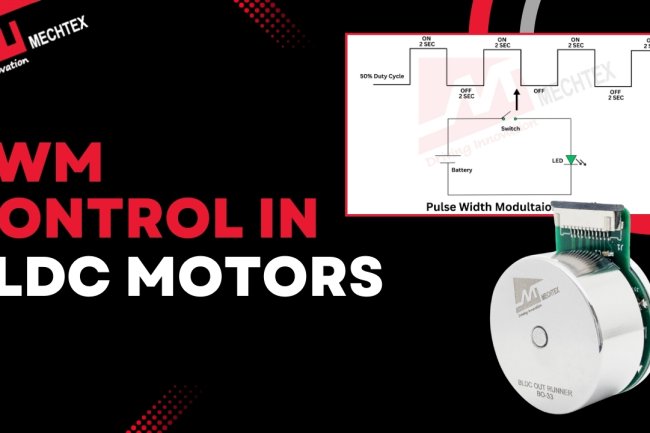

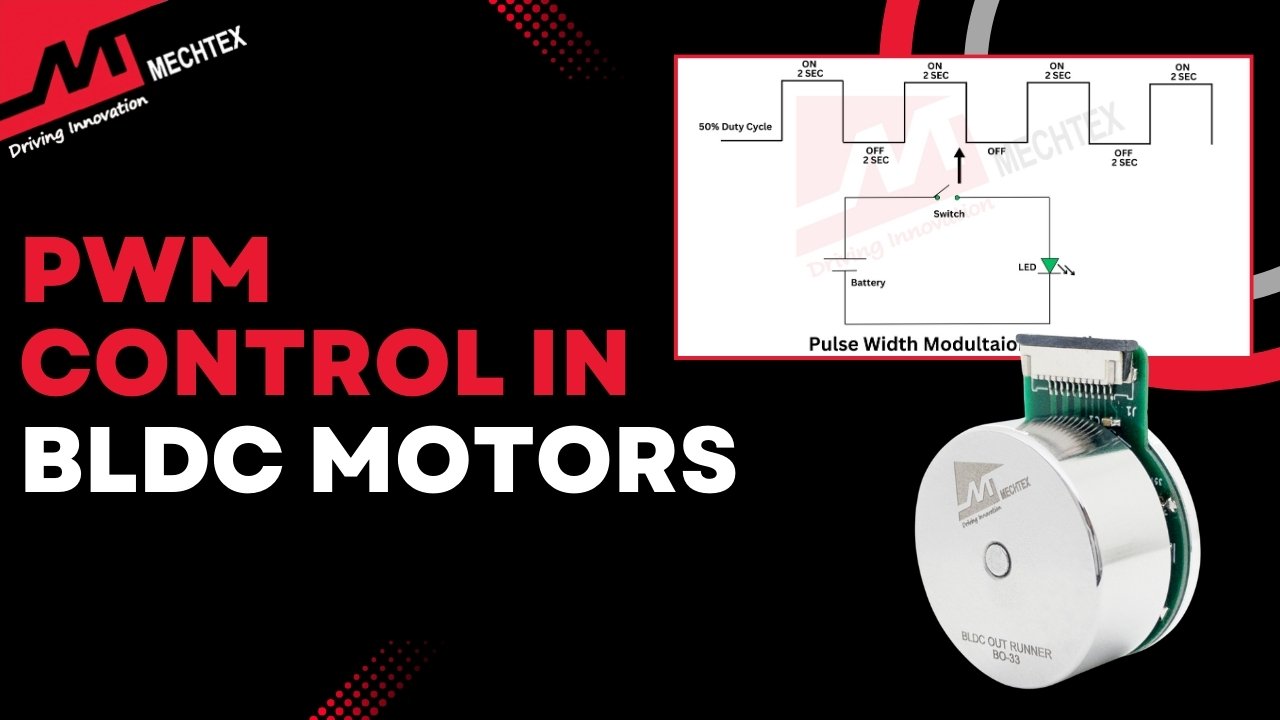

This rapid switching of current can generate voltage spikes and electromagnetic interference (EMI), which manifests as high-pitched noise and contributes to signal interference. This type of noise is typically more prominent at higher PWM (Pulse Width Modulation) frequencies.

- Mechanical Noise

Mechanical components such as bearings, shafts, and housing are prone to generating noise due to physical movements and vibrations. The primary contributors are:

-

-

-

-

- Bearing Noise: Worn or low-quality bearings create vibration and friction, resulting in a humming or grinding noise, especially at high speeds.

-

- Rotor Imbalance: If the rotor mass is unevenly distributed, it causes an imbalance in rotation, which leads to noise and vibration.

-

- Shaft Misalignment: Misalignment between the shaft of the BLDC motor and its load can cause uneven torque transmission and noise.

-

-

-

- Magnetic Noise

Magnetic noise is generated due to the interactions between the stator teeth and the rotor magnet. This non-uniform magnetic interaction causes a phenomenon known as cogging torque. This led to pulsating motion and an audible loud noise at low speeds.

- Commutation Noise

BLDC motors rely on electronic commutation using sensor-based or sensorless control techniques. Poor commutation technique or incorrect signals from the hall effect sensor can result in uneven torque and cause a buzzing sound.

- Structural Resonance

Each component in the motor assembly has its natural frequency. When the motor’s operating frequency coincides with these natural frequencies, resonance occurs. This resonance amplifies vibrations and significantly increases noise levels.

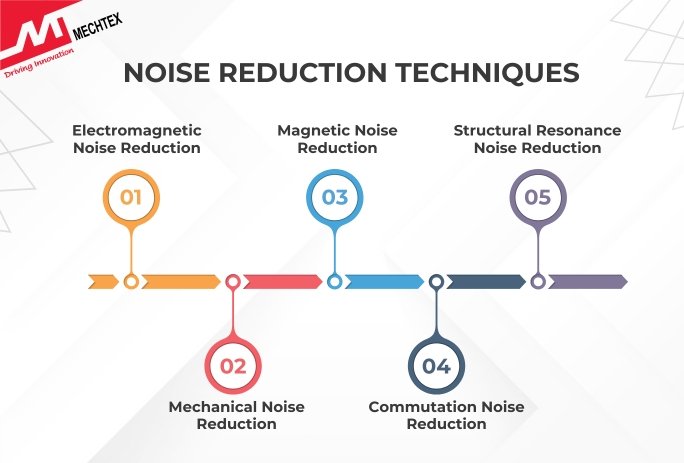

Noise Reduction Techniques for BLDC Motors

Reducing noise in BLDC motors is essential for ensuring optimal performance in precision-critical and noise-sensitive applications such as medical devices, HVAC Systems, and industrial automation.

Below are the effective techniques to minimise the different types of noise of BLDC motors:

1. Electromagnetic Noise Reduction

-

-

-

- Use of Low-EMI Drivers: Employ motor controllers specifically designed to reduce electromagnetic Interference (EMI).

-

- Optimised PWM Switching Frequency: Adjust the PWM frequency to a range that minimises audible noise typically above 20 kHz (above the human hearing range).

-

- Shielded Cables & PCB Grounding: Use shielded wires and proper PCB layout techniques to reduce EMI propagation.

-

- EMI Filters and Ferrite Beads: Install filters and ferrite components on power and signal lines to absorb and suppress high-frequency noise.

-

-

2. Mechanical Noise Reduction

-

-

-

- Precision Bearings: Use high-quality, low-friction bearings to reduce vibrations and audible noise.

-

- Dynamic Rotor Balancing: Ensure the rotor is dynamically balanced to avoid imbalance-related vibrations.

-

- Proper Shaft Alignment: Maintain accurate alignment between the BLDC motor shaft and load to prevent mechanical distortion.

-

- Lubrication: Periodic lubrication of bearings helps reduce friction-induced noise.

-

-

3. Magnetic Noise Reduction

-

-

-

- Skewed Stator Slots: Slightly aligning the stator slot reduces cogging torque and its associated noise.

-

- Distributed Windings: Using distributed windings instead of concentrated windings, smoothen magnetic flux transitions.

-

- Optimised Pole-Slot Combination: Design motor geometry to minimise magnetic interaction irregularities.

-

-

-

-

-

- Use of Magnetic Damping Materials: Introduce composite materials that dampen magnetic noise and reduce structural vibrations.

-

-

4. Communication Noise Reduction

-

-

-

- Field-Oriented Control (FOC): Implement field-oriented control (FOC) instead of trapezoidal control for smoother, quicker torque generation.

-

- Accurate Hall Sensor Calibration: Ensure precise positioning and calibration of the hall sensor to avoid miscommunication.

-

- Sensorless Algorithms with Filtering: Advanced sensorless control using back-EMF detection with signal filtering helps reduce abrupt torque changes.

-

-

5. Structural Resonance Noise Reduction

-

-

-

- Vibration Dampers and Isolators: Use rubber mounts, dampers, or isolators to absorb and suppress resonant vibrations.

-

- Structural Stiffening: Reinforce motor housing and mounts to shift the natural frequency away from operating ranges.

-

- Noise-Absorbing Materials: Apply acoustic foam or damping sheets in the enclosure to absorb sound waves.

-

-

Conclusion

Noise reduction in BLDC motors is a multidimensional challenge requiring mechanical precision, electromagnetic refinement, and intelligent control strategies. As industries push for quieter and more efficient solutions—especially in medical, HVAC, and robotics—the importance of well-designed, low-noise BLDC motors continues to rise.

By integrating the above techniques, BLDC motor manufacturers can deliver motors that not only meet performance and efficiency goals but also maintain low acoustic and vibrational footprints. As noise becomes a benchmark for quality, focusing on its reduction is no longer optional—it is essential.