Working of Hybrid Stepper Motor

Hybrid stepper motor operates by combining the principles of both permanent magnet (PM) stepper motor and variable reluctance (VR) stepper motor.

What is a Hybrid Stepper Motor?

The hybrid stepper motor is a type of motor that combines the features of both permanent magnet (PM) stepper motor and variable reluctance (VR) stepper motor. It is designed to offer the benefits of both types of stepper motors with minimum drawbacks.

A hybrid stepper motor consists of a stator and rotor. A rotor is made up of a cylindrical permanent magnet with teeth in its circumference. While the stator consists of two or more phases of electromagnet arranged around the rotor.

The operating principle of a hybrid stepper motor is a combination of the PM stepper motor and VR stepper motor principles. When the phase of the stator is energized, it creates a magnetic field and interacts with the magnetic field of the rotor. This interaction causes the rotor to align itself with the energizing phase and minimizes the reluctance to achieve a stable position.

Hybrid stepper motors offer several advantages over PM stepper motors and VR stepper motors. One of the advantages of hybrid stepper motors is their high torque density. The combination of both PM stepper and VR stepper motor principles results in higher torque output and makes the hybrid stepper motor more efficient and compact.

Another advantage of a hybrid stepper motor is its high-holding torque. The permanent magnet in the rotor provides a high holding torque even when the motor is not energized. It prevents the hybrid stepper motor from losing its position.

Furthermore, a hybrid stepper motor also offers improved efficiency as compared to other types of stepper motors. The permanent magnet in the rotor reduces the amount of energy required to maintain its position which leads to higher efficiency and low power consumption.

Hybrid stepper motors are widely used in applications that require precise positioning such as 3D printers, industrial automation, robotics, and other motion control solutions. This motor offers a good balance between torque, precision, and efficiency which makes them a popular choice in many industries.

Also Read

What is Hybrid Stepper Motor | Introduction & Components

Working of Hybrid Stepper Motor

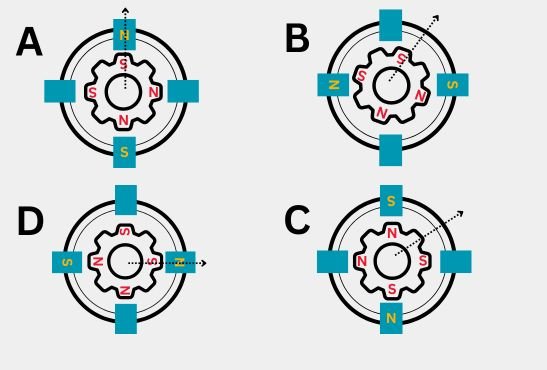

Hybrid stepper motor operates by combining the principles of both permanent magnet (PM) stepper motor and variable reluctance (VR) stepper motor. This motor consists of a rotor and stator. The rotor consists of permanent magnets while the stator is equipped with windings. The rotor is divided into two parts, each part having teeth that enhance magnetic field interaction with the stator.

When the current flows through the stator’s winding, it generates a magnetic field. This magnetic field interacts with the rotor's permanent magnet and causes the rotor to rotate.

By sequentially energising the stator windings in a predetermined order, the magnetic field rotates around the stator and pulls the rotor along with it in discrete steps. Each step typically corresponds to the specific angle of rotation. The most common step angle is 1.8 degrees, but it can vary depending on the motor’s design.

The working of a hybrid stepper motor heavily relies on its internal structure. The stator has multiple poles with windings. While The rotor has multiple teeth surrounding the stator and forms the north and south poles. When stator windings are energized, it creates a magnetic north and south pole. These poles attract and repel the corresponding north and south poles of the rotor.

As different stator windings are energized sequentially, the rotor is forced to move from one position to another. This movement is incremental and occurs in discrete steps, which provides a high level of precision to the stepper motor

The movement of the hybrid stepper motor can controlled with the help of a driver circuit. This circuit sends current pulses to the stator winding in the sequences. Each pulse corresponds to the single step of the rotor. The frequency and sequence of this pulse determine the speed and direction of the hybrid stepper motor. The motor can be driven in various modes such as full-step mode, half-step mode, and micro-stepping mode depending upon the precision and smoothness required.

Also Read

Explore the Different Stepping Modes of Stepper Motor

The performance of the hybrid stepper is further enhanced by its construction. The rotor’s teeth and stator’s poles create a series of preferred magnetic positions or detent positions where the rotor tends to rest when the stator windings are de-energized. This magnetic detent torque provides a holding force and ensures the rotor stays in between steps.

By carefully designing the number and arrangement of rotor teeth and stator poles, engineers can customize the hybrid stepper motor for specific applications by achieving a balance between torque, speed, and precision.