The Role of Microcontrollers in BLDC Driver

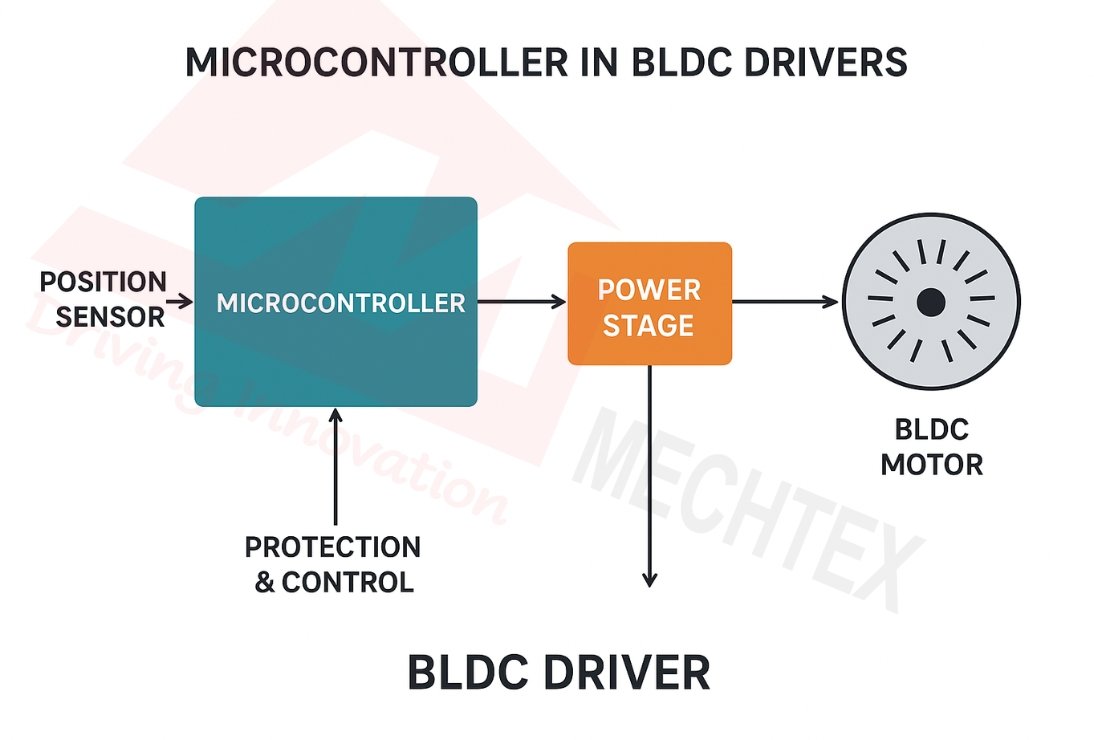

A microcontroller (MCU) is a compact integrated circuit designed to perform specific control tasks with electronic control devices. A microcontrollers in the BLDC driver perform several roles by integrating hardware management and software intelligence.

BLDC drivers are crucial components in modern BLDC motors, ensuring that they operate with efficiency, precision and reliability. Unlike a traditional brushed DC motor setup, BLDC motors cannot function without a driver that manages the electronic commutation.

The drivers are sophisticated control electronics system that manages the commutation and performance of the BLDC motor. This is where Microcontrollers (MCUs) come into the role.

Microcontrollers serve as the brain of the BLDC drivers. They help execute complex algorithms, controlling power switches, and also assist in speed regulation, torque optimisation, and fault protection.

In this blog, we will explore the importance of microcontrollers in BLDC drivers, their functions, control techniques, and real-world applications.

What is a Microcontroller (MCU)

A microcontroller (MCU) is a compact integrated circuit designed to perform specific control tasks with electronic control devices. It contains a CPU, memory (RAM & ROM) and input/output peripherals on a single chip. It enables to processing of data, executing instructions, and interacting with sensors and hardware.

Unlike other controllers, microcontrollers (MCUs) are optimised for embedded applications to enable real-time control, low power consumption, and cost effectiveness.

MCUs are used in a wide range of applications, such as automotive systems, robotics, and conveyors, where precise timing, automation, and decision-making are required without relying on external computers.

Why BLDC Motors Require Microcontroller-Based Drivers

BLDC (Brushless DC) motors operate using electronic commutation instead of mechanical brushes. In electronic commutation, the position of the rotor must be monitored continuously to determine which stator windings need to be energised at a given time to enable precise and accurate performance.

This requires real-time decision-making and control algorithms for better performance. This can be done with the help of microcontrollers (MCUs).

A microcontroller provides:

- Real-time rotor position tracking through hall sensors and feedback systems.

- Enables precise timing for switching power transistors such as MOSFETs or IGBTs

- Provides closed-loop control systems for speed - torque adjustments.

- It provides programmability to allow the BLDC driver to function with various applications.

Without the microcontrollers in the BLDC driver, the control of the BLDC motor would be inefficient and limited to basic functionality.

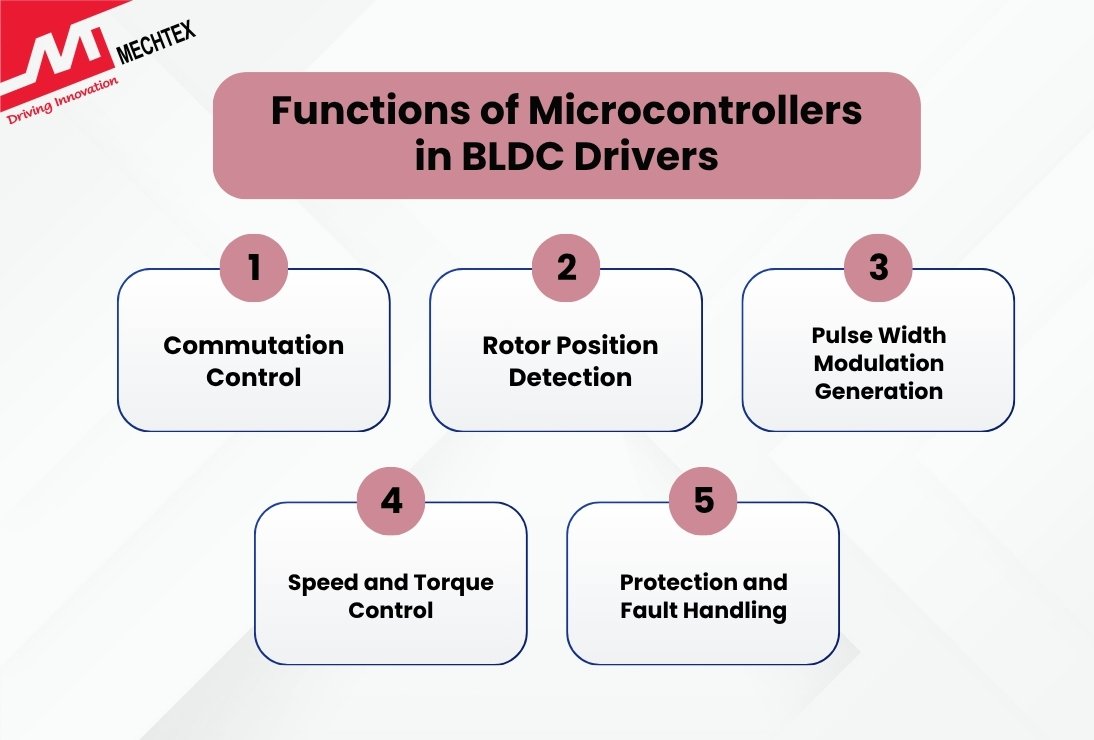

Functions of Microcontrollers in BLDC Drivers

A microcontrollers in the BLDC driver perform several roles by integrating hardware management and software intelligence. Some of the key roles/functions of Microcontrollers are:

- Commutation Control

The most critical function in a BLDC motor is electronic commutation. In the commutation, Microcontrollers (MCUs) determine which phase windings to be energised based on the rotor position. Depending on the design of BLDC motors, commutation methods can be classified as:

-

- Six-step trapezoidal commutation: It is the simplest and widely used commutation method in BLDC motors.

- Sinusoidal commutation: It enables smooth torque and lower harmonics in BLDC motors.

- Field-Oriented Control (FOC): It is one of the most advanced and highly efficient commutation methods of the BLDC motor.

- Rotor Position Detection

- In Sensor-based control techniques, Hall sensors help the Microcontrollers (MCUs) to process the digital signals to detect the position of the rotor for smooth commutation.

- In sensorless control techniques, the MCUs estimate the position of the rotor with the help of Back-EMF for precise movements.

- PWM Generation

Pulse-Width Modulation (PWM) generation is the key function of MCUs in BLD drivers. The MCU produce high-frequency PWM signals which control the gate drivers of MOSEFTs and IGBTs.

By varying the duty cycle of these signals, the voltage applied to the motor windings changes and helps to regulate the torque and speed of the BLDC motor.

- Speed and Torque Control

In the BLDC driver, the MCUs use feedback loops from sensors to regulate the performance of the motor. By continuously monitoring the speed and torque, it dynamically adjusts the PWM cycle to match the desired setpoints.

As a result, the BLDC motor maintains a consistent speed, torque and high efficiency across various operating conditions.

- Protection and Fault Handling

Microcontrollers (MCUs) provide the following safety features:

-

- OverCurrent Protection

- OverVoltage Protection

- Thermal Shutdown

- Stall Detection

Control Techniques Enabled by Microcontrollers

Microcontrollers enable various control techniques for BLDC motors depending on the conditions and applications. Some of the important control techniques are:

- Trapezoidal Control (Six-Step)

It is the simplest commutation method in a BLDC driver with six commutation states every cycle. It is easy to implement and a cost-effective commutation method. But it has some drawbacks such as torque ripple, noise creation and less smoothness.

Despite these drawbacks, it is a cost-sensitive technique and is used in applications such as fans, pumps, and basic automation systems.

- Sinusoidal Control

It drives BLDC motors with a smooth, sinusoidal current waveform instead of discrete steps. It reduces the torque ripple and noise, which results in quieter and more efficient operation.

Also, it demands sophisticated complex algorithms, while modern MCUs easily handle the process and make the technique suitable for applications such as robotics, high-end fans, and precision machinery.

- Field Oriented Control (FOC)

It is an advanced vector control method for BLDC motor. It independently regulates the torque and magnetic flux of the BLDC motor, which enables precise control and smooth working.

The FOC technique offers high efficiency, smooth response, and accurate speed torque management. It makes them ideal for applications such as robotics, drones, electric vehicles, and industrial automation.

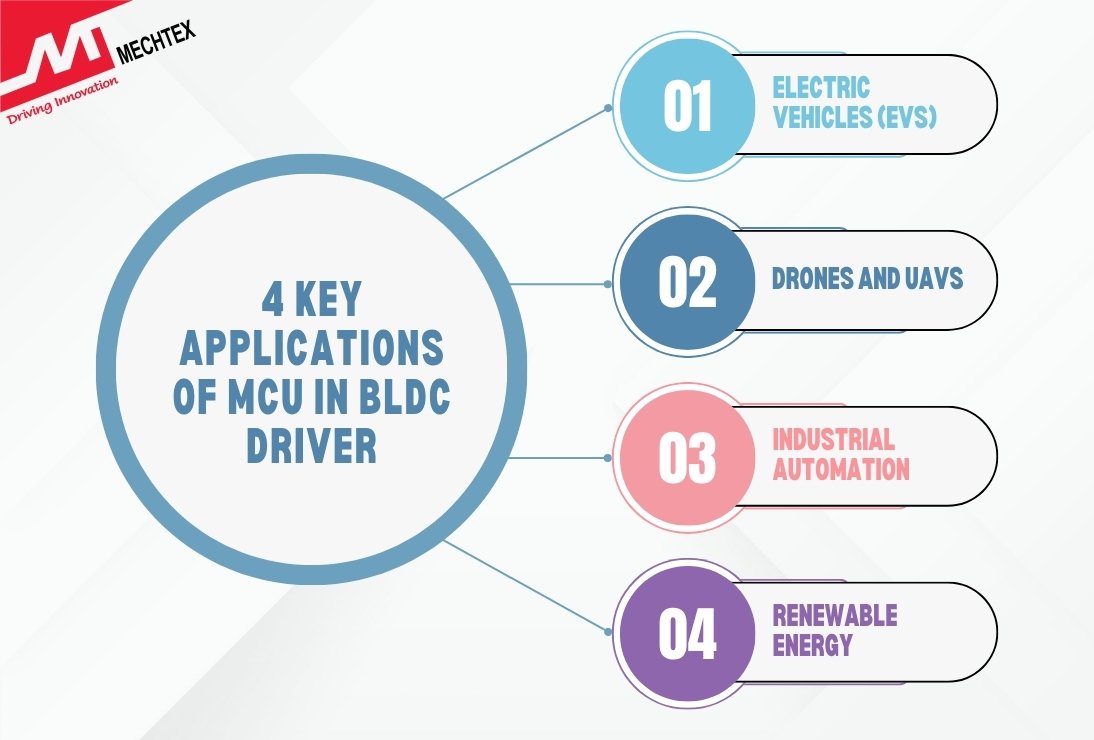

Applications of Microcontroller-Based BLDC Drivers

The combination of the BLDC motor, its driver and the microcontroller (MCU) powers a wide range of applications. Some key applications are:

- Electric Vehicles (EVs)

BLDC drivers with MCUs manage the performance of BLDC motors to ensure high efficiency and regenerative braking.

- Drones and UAVs

MCUs enable precise speed control and fast dynamic response by adjusting PWM and sensor feedback in real time to ensure stable flight, accurate manoeuvring, and efficient thrust management under varying conditions.

- Industrial Automation

Applications such as robotics, CNC machines, and conveyors use BLDC drivers with MCU-based FOC for precise torque, smooth speed control and high efficiency to enable precise movements, smooth operation, and reliable performance.

- Renewable Energy

BLDC motors are used in solar trackers, and wind turbines use MCU-based control techniques to optimise efficiency, adjust positioning, and adapt to changing environmental conditions.

Conclusion

The role of microcontrollers in BLDC drivers is indispensable. They provide the intelligence and flexibility required to transform a BLDC motor into a highly efficient, controllable, and safe system.

From basic commutation control to advanced vector control strategies, microcontrollers enable industries to harness the full potential of BLDC motors.

As applications demand greater efficiency, connectivity, and adaptability, the synergy between microcontrollers and BLDC motors will only deepen.

Whether in electric mobility, industrial automation, or smart home devices, the microcontroller-based BLDC driver remains at the heart of innovation.