Stepper Motor Applications: Robotics, 3D Printers, CNC, & Medical Uses

Discover stepper motor applications — from CNC machines, robotics, and 3D printers to medical devices, automotive systems, automation lines, and precision control in consumer electronics.

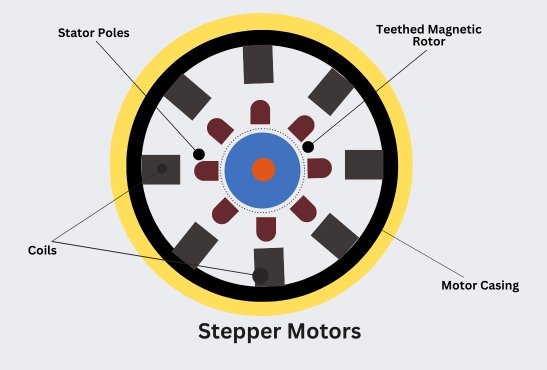

What is a Stepper Motor?

A stepper motor is an electrical motor that converts electrical pulses into discrete angular movements. Unlike other traditional motors, that rotate continuously, stepper motors move in precise angular steps making them ideal for applications requiring accurate positioning and control.

The stepper motor consists of a rotor with a permanent magnet and a stator with electromagnets arranged in a specific pattern. When electrical pulses are supplied to the stator windings, they create a magnetic field that attracts the rotor's permanent magnet. These pulses cause the rotor to rotate at a specific angle known as step angle. The number of steps per revolution determines the stepper motor resolution and dictates its accuracy and smoothness.

Stepper motors offer several advantages over traditional motors such as high torque at low speeds, precise positioning capabilities, accurate controllability, and relatively simple control circuitry. However, their performance can be affected by factors such as operating speed and load, as their torque output decreases with increasing speed and many more.

Despite several limitations, stepper motors are commonly used in a wide range of applications such as robotics, CNC machines, 3D printers, medical equipment, and automated manufacturing machinery where precise speed control and accuracy are necessary.

Also Read

What is a Hybrid Stepper Motor

Applications of Stepper Motor

Stepper motors are widely used in various applications such as 3D printers, Medical Devices, ATM machines, Home automation systems, and many more due to their precise control over position, speed, and accuracy.

Here are some common applications of stepper motors:

- 3D Printer

Stepper motors are essential components in 3D printers due to their precise control over the position and speed of the motor.

Unlike traditional DC motors that rotate continuously, stepper motors move in small steps and enable precise positioning and holding of the printing head. This precise positioning is essential for creating 3D models.

Stepper Motors also provides high torque at low speeds which ensures the printing head can move smoothly and maintain its position under different load conditions. This motor also offers excellent holding torque which prevents unwanted movement during printing.

Additionally, stepper motors are easy to control and require simple digital signals to operate. This simple control system allows direct integration with the 3D printer boards and enables precise movement and real-time adjustment.

Furthermore, stepper motors are robust and capable of withstanding the demanding conditions of 3D printers such as high-temperature and continuous operation.

Mechtex Nema 17 Stepper Motor is a versatile and powerful stepper motor. With a holding torque ranging from 19 cNm to 47 cNm and a current capacity of 0.4 Amps to 2.3 Amps, it is an essential component of a 3D Printer.

- CNC Machines

Stepper motors are a crucial component in CNC machines due to their unique characteristics of precisely aligning with different operating systems as per the requirement.

Stepper motors have the ability to move in discrete steps with the help of electrical pulses, which results in exceptional positioning accuracy and repeatability. This precise control enables the creation of intricate designs with minimal error to ensure high-quality outputs.

Stepper motors also offer excellent holding torque, which allows them to maintain their position even under different load conditions. This feature prevents the unwanted movement of the CNC machine during the operation. This feature is important in machining the intricate parts that require precise positioning and stability.

Furthermore, stepper motors are easy to control and require minimal control devices which makes them easy to integrate into CNC machines and a cost-effective solution. Stepper motors are robust and have the ability to operate under different environmental conditions which contributes to the sustainability of CNC machines.

Mechtex Nema 23 Stepper Motor is a versatile and robust stepper motor. With holding torques ranging from 19 cNm to 47 cNm and current capacities between 0.4 Amps to 2.3 Amps it is a crucial component of CNC machines.

- Robotics

Stepper motors are extensively used in robotics due to their exceptional controllability, precision, and torque.

Stepper motors offer precise angular positioning and control rotation which makes them ideal for robotics applications that require accurate movement and fine control.

Unlike traditional DC motors, stepper motors divide their steps into smaller steps, enabling precise positioning and accurate movement for the manipulation of robotics joints and effectors.

Additionally, stepper motors offer high torque at low speeds which enables robots to handle heavy loads and overcome the initial forces effectively.

Further, stepper motors are simple to control and easily integrate with robotic systems, which reduces the system’s complexity and makes it a cost-effective solution for various robotics applications.

Mechtex Nema 24 Stepper Motor is a powerful stepper motor. With a holding torque of 160 cNm and a current capacity ranging from 2.6 Amps to 4.2 Amps it is a pivotal component of robotics applications.

- Medical Devices

Stepper motors are extensively used in medical devices due to their precision, reliability, and accuracy.

Stepper motors provide precise control over the angular movement which allows for precise positioning and movement of surgical tools, and diagnostic equipment. Their ability to hold position without any power consumption makes them ideal for applications such as robotic surgery, and image-guided therapy where precise positioning is crucial.

Additionally, stepper motors offer high torque at low speed which makes them suitable for applications such as surgical drills, and endoscopes where strong and controlled movement is required.

Stepper motors are compact in size and have the ability to operate under various environmental conditions which makes them an ideal choice for applications such as MRI suites, CT scanners, and cleanrooms.

The reliability and durability of stepper motors ensure consistent and efficient performance in a wide range of medical devices.

Mechtex MTS7a is a 12V unipolar stepper motor. It supports both bipolar and unipolar winding configurations which offers flexibility and becomes an ideal choice for medical devices.

- Industrial Automation

Stepper motors are widely used in various industrial automation devices such as conveyor belts, pick and place machines, and various automated systems due to precise positioning and accurate movement.

Stepper motors have precise angular control and the ability to be easily integrated with digital control systems which makes them ideal for applications that require precise and repeatable movements.

Stepper motors also offer precise positioning and control over the speed and direction of the motor which enables the accurate movement of the objects and becomes an ideal solution for conveyor belts and pick-and-place machines.

Furthermore, the digital nature of the stepper motor allows for easy integration with micro-controllers and computers which provides flexibility in the programming of automated systems. Also, their compact size and high torque to volume ratio make them an ideal choice for applications where space is constrained.

Mechtex MTS8c is a 12V DC stepper motor. It supports both bipolar and unipolar winding setups which offers precision in operation and becomes an ideal choice for Industrial Automation Applications.

Conclusion

Stepper motors with their ability of precision and controlled movement, have become a crucial component in a wide range of applications across various industries. From medical devices to robotics, and automated manufacturing machines stepper motors have revolutionised ways to control and manipulate objects. Their ability to move in discrete steps with precise positioning and holding torque makes them for applications where accuracy is required.

Stepper motors also enabled us to automate the complex process with improved efficiency and create innovative solutions. Their compact size, low maintenance requirements, and cost-effectiveness further enhance their usability in applications.

As technology continues to evolve, stepper motors are poised to play a more significant role in shaping the future of automation and precise control.