Applications of DC Gear Motor

DC gear motors are the combination of a DC motor and a gearbox, which can be used in a wide range of applications such as robotics, medical equipment, Industrial machinery and other due to their compact size and capability of delivering high torque at low speeds.

DC gear motors are an integral part of modern electromechanical systems. These compact, high-torque motors combine the speed of a DC motor with the torque of a gearbox, which results in offering a versatile solution for a wide range of applications.

From robotics and industrial automation to medical devices and consumer electronics, DC gear motors have become an indispensable component due to their precision, reliability, and adaptability.

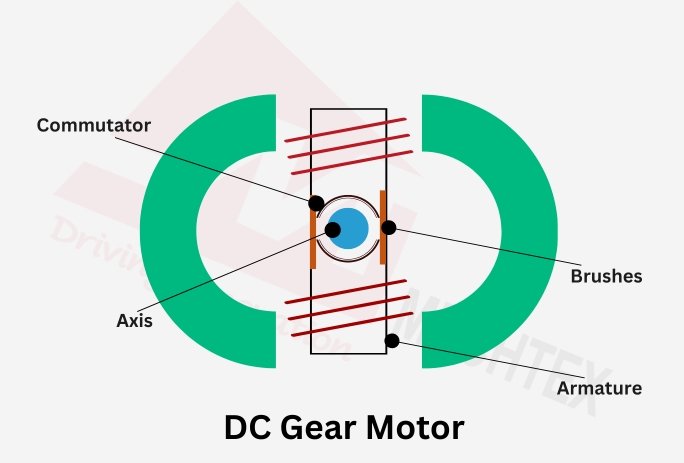

What Is a DC Gear Motor?

A DC gear motor is a combination of a DC motor with a gearbox to reduce the speed and increase the torque for smooth and precise operation. This combination allows for controlled movement and high torque output at low speed, under varying load conditions.

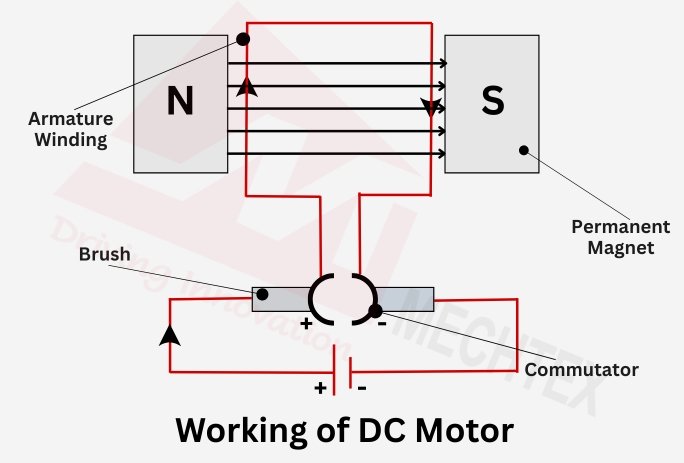

The DC motor converts the electrical energy into mechanical motion through electromagnetic interaction of stator and rotor. When voltage is applied, the rotor spins and produces rotational movement. However, this motor delivers high speed, which limits its uses for applications demanding high torque tasks.

To address this limitation, a gearbox is attached to the DC motor. The gearbox consists of gears which reduce the speed of the motor and allow the high torque output.

By using various gear ratios, one can effectively reduce the speed of the motor while proportionally increasing the torque. This balance of speed and torque is essential for consistent and reliable performance

DC gear motors offer several advantages, such as compact design, high torque at low speed, energy-efficient usage, and others, which make them ideal for various mechanical devices.

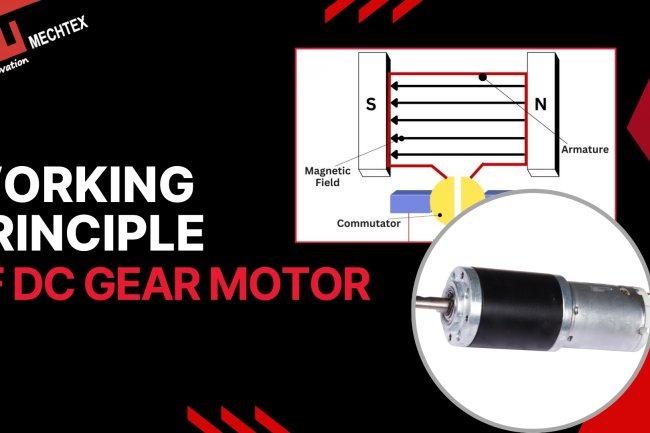

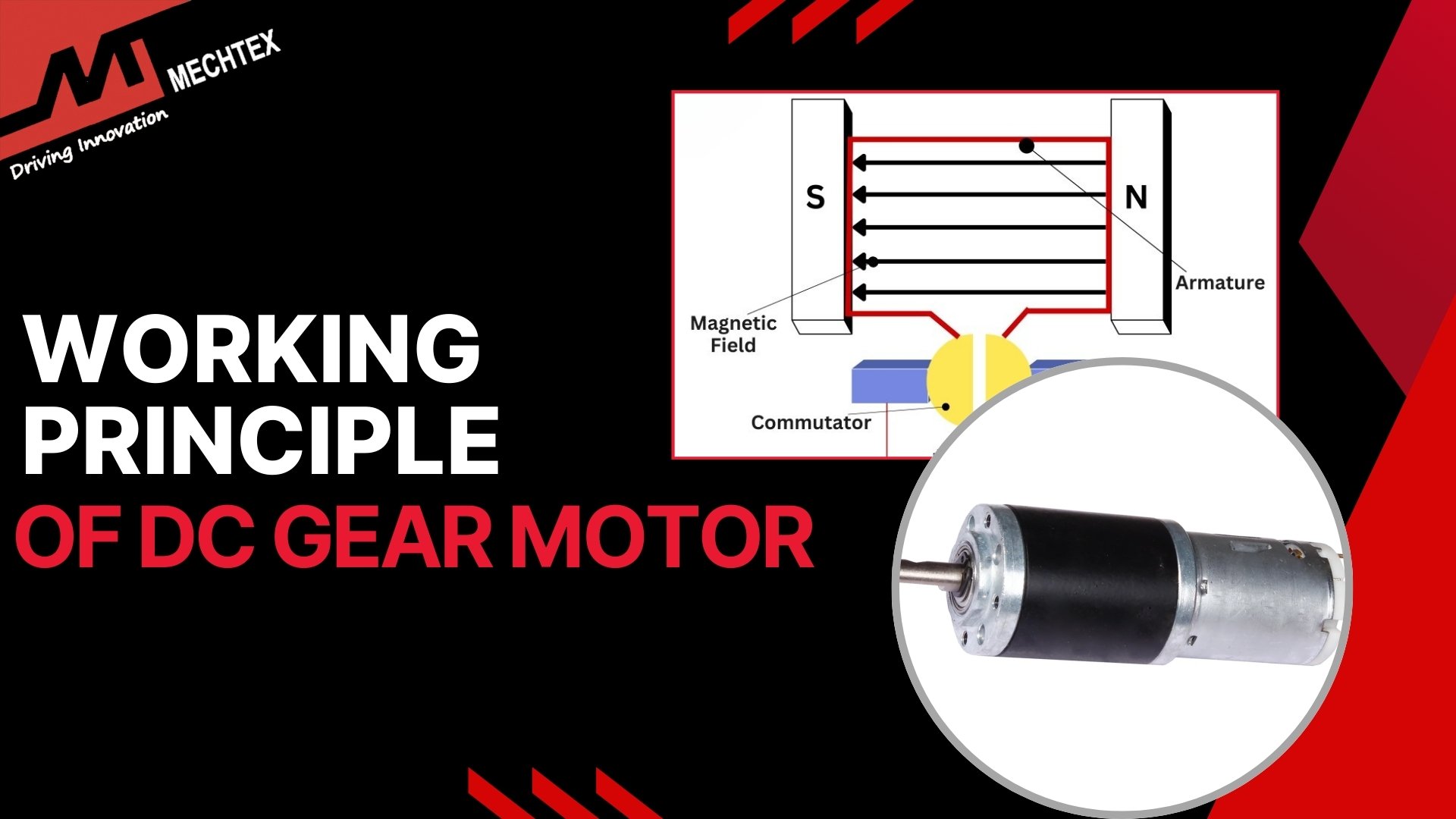

Working Principle of DC Gear Motor

A DC gear motor is an electric motor which operates by converting electrical energy into mechanical movement.

When voltage is applied to the motor terminals, the current flows through the armature windings and generates a magnetic field. This magnetic field interacts with the stator and produces torque that causes the rotor to spin.

Attached to the DC motor is a gearbox, which plays a crucial role in modifying the speed and torque of the motor. The gearbox reduces the speed of the motor shaft to lower the speed of the output shaft. This speed reduction increases the torque output, allowing the motor to handle loads and provide more controlled movements.

Applications of DC Gear Motor

DC gear motors are compact, efficient, and capable of delivering high torque at low speeds, making them ideal for a wide range of applications across industries. Here is the list of applications of the DC gear motor:

- Robotics:

One of the most prominent applications of the DC gear motor is robotics. Where it is autonomous mobile robots, robotic arms, or pick-and-place machines. DC gear motors are used for:

-

-

-

-

- Precise joint movement

- Controlled actuation of grippers

- Driving wheels or tracks

-

-

-

The DC gear motor's ability to regulate speed and torque allows robots to perform delicate tasks such as assembly, sorting, or object manipulation with high accuracy.

Use Case: In warehouse automation, mobile robots driven by DC gear motors can transport goods, improving logistics efficiency and reducing manual labour.

DC gear motors are widely adopted in medical devices due to their quiet operation, compact size, and precision control. Applications include:

-

-

-

-

- Infusion pumps

- Hospital beds

- Surgical tools

- Dental chairs

-

-

-

DC gear motors used in medical applications are designed to meet strict reliability standards to ensure safe operations.

In industrial automation, DC gear motors are vital components that require high torque and accurate speed control. Applications include:

-

-

-

-

- Conveyor belts

- Labeling machines

- Packaging equipment

- Material handling systems

-

-

-

DC gear motors provide the torque necessary to drive mechanical loads with precision, ensuring seamless integration with programmable logic controllers (PLCs) for factory automation.

Use Case: In bottling plants, gear motors control conveyor systems that transport bottles through various stages—filling, capping, and labelling—at consistent speeds.

- Consumer Electronics and Home Automation

Many consumer electronics and home automation devices rely on the efficiency and reliability of DC gear motors. They are embedded in systems requiring compact motion control solutions, such as:

-

-

-

- Automatic curtain systems

- CD/DVD drives

- Camera auto-focus mechanisms

- Coffee makers and blenders

-

-

Use Case: In smart home systems, DC gear motors power automated blinds, smart locks, and window openers, offering enhanced convenience and energy efficiency.

Conclusion

DC gear motors are foundational components that power automation, enhance user convenience, and improve machine performance across multiple sectors. Their combination of torque, control, and flexibility enables engineers and designers to create reliable and efficient systems tailored to specific needs.

Whether you're designing a solar-powered tracker, a smart home appliance, or an industrial robot, understanding the applications of DC gear motors opens the door to countless innovation opportunities.