What is a DC Gear Motor

DC gear motor is a type of electric motor that combines a standard DC motor with a gearbox.

What is a DC Gear Motor?

DC gear motor is a type of electric motor that combines a standard DC motor with a gearbox. This integration allows for increased torque output and reduced rational speed, which makes it suitable for applications that require high torque and precise output.

DC gear motor consists of a permanent magnet or electromagnet stator and a mature wound with the coil. When an electric current flows through the armature coils, it creates a magnetic field that interacts with the stator and generates torque that causes the armature to rotate.

The gearbox attached to the DC motor contains a series of gears that convert the motor’s high speed and low torque output to low speed and high torque output. These gears can be of various types such as spur gears, planetary gears, and helical gears, each offering different benefits in terms of efficiency, noise reduction, and load capacity.

One of the primary advantages of DC gear motor is its considerable increase in torque output. The reduction of speed through the gearbox allows the motor to provide greater force and makes it suitable for heavy-duty applications.

Another advantage of a DC gear motor is they offers excellent speed control. It can be controlled by adjusting the voltage supplied to the motor. This precise speed control is useful for applications that require accurate positioning and smooth operation.

DC gear motors are widely used in various applications. In robotics, they provide precise movement and high torque to robotics arms. In the automotive industry, high torque DC geared motors are used in power windows, windshield wipers, and seat adjustment.

In industrial applications, they are used in conveyor belts, pumps, and other machinery. Sometimes, they are also found in various home appliances.

Working Of DC Gear Motor

A DC gear motor is a combination of a DC motor and a gearbox. It works on the principle of electromagnetic induction, where a current-carrying conductor placed in magnetic fields, experiences a force and causes the rotation of the motor. The gearbox is used to increase or decrease the speed of the motor depending on application requirements.

The DC motor consists of two main components: stator and rotor. The stator consists of permanent magnets or electromagnets that create a stationary magnetic field. At the same time, the rotor consists of an armature coil that carries electricity. The gearbox is connected to the shaft of the DC motor. It consists of a series of gears that transmit the rotational motion from the motor to its output shaft.

When the power is supplied to the DC motor, the armature coil energises and creates a magnetic field. The stationary magnetic of the stator interacts with the magnetic field of the armature coil and causes the rotor to rotate. Then the rotational motion of the motor is transmitted to the gearbox.

The gears in the gearbox either increase or decrease the speed and torque of the DC motor. Then the output shaft of the gearbox rotates at the desired speed and the torque as per the application’s requirement.

Applications of DC Gear Motor

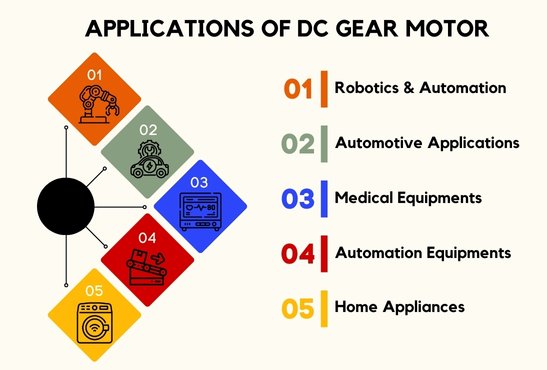

DC gear motors are used in a wide range of applications across various industries due to their ability to provide precise control over the speed and torque.

Here are some common applications of DC gear motors:

- Robotics and Automation

DC gear motors are used in robotics systems for driving robotic arms, grippers, and other equipment that require precise speed control. They are also used in automated assembly lines, pick and place machines, and material handling equipment.

- Automotive Applications

DC gear motors are used in power windows, sunproof, and other automotive accessories for controlling their movement. They are also used in various automotive systems such as windshield wipers and power seat adjustments.

- Medical Equipment

DC gear motors are used in medical equipment such as hospital beds, wheelchairs, and rehabilitation equipment for positioning and adjustment of patients.

- Automation Equipment

DC gear motors are used in automated doors, gates, and window openers for controlling the opening and closing mechanism. They are also used in various industrial automation equipment such as conveyor belts, packaging machines, and sorting systems.

- Home Appliances

DC gear motors are found in household appliances such as washing machines, dishwashers, and vacuum cleaners to drive their mechanism.