Understanding Power Factor Correction Using Synchronous Motors

Power factor correction is the process of improving the power factor of an electrical system. Synchronous motors can be used for power factor correction by adjusting their excitation current to improve the overall efficiency of the system. It is essential for optimising electrical systems & reducing losses to improve overall efficiency.

Power factor correction is important for improving the efficiency of electrical systems, reducing losses and optimising the use of energy. Synchronous motors play a crucial role in achieving effective power factor correction due to their ability to operate at both leading and lagging power factors. In this blog, we will explore the understanding of power factor correction and its importance, and how it is used in various applications to improve their efficiency.

What is Power Factor Correction (PFC)?

Power factor correction is the process of improving the power factor of an electrical system. The power factor is a measure of how effectively electrical power is converted into useful work. It is defined as the ratio of power (measured in kilowatt) to apparent power (measured in kilovolt-amperes, kVA).

The power factor can be calculated using the following formula:

PF= P/S

Where

P is the power in KW

S is the apparent power in kVA

The power factor ranges from 0 to 1. When the power factor is close to 1 (unity), the application is more efficient as more power is used for productive work. A lower power factor indicates poor utilisation of electrical power, leading to a high loss of energy.

Power Factor Correction Using Synchronous Motors

A synchronous motor is an AC motor that operates at a constant speed synchronised with the frequency of the supply. Unlike induction motors, where the rotor lags behind the stator’s magnetic field, synchronous motors rotor matches the stator’s magnetic field to ensure constant operation.

Watch the YouTube video by "The Engineering Mindset" to understand the concept of power factor correction using different motors.

Synchronous motors can be used for power factor correction by adjusting their excitation current. The key principle that allows synchronous motors to correct the power factor is their ability to operate at various modes.

Three modes of synchronous motor for power factor correction are:

- Under Excitation Mode (Lagging Power Factor)

When the excitation current is below the normal level, the synchronous motor draws reactive power from the system resulting in a lagging power factor.

- Normal Excitation Mode (Unity Power Factor)

At normal excitation mode, the synchronous motor neither supplies nor absorbs reactive power resulting in a unity power factor (PF = 1).

- Over Excitation Mode (Leading Power Factor)

When the excitation current is increased above normal levels, the synchronous motor supplies reactive power to the system resulting in a leading power factor.

By operating in the over-excited mode, the synchronous motor can act like a capacitor and provide a leading power factor, compensating for the lagging reactive power drawn by inductive loads. This reduces the total reactive power in the system, thus improving the power factor.

Power Factor Correction Calculation

To determine the amount of power factor correction needed in a system, reactive power factor and desired power factor are necessary. Power factor correction can be calculated using the following formula:

Q = P x (tanΘ1 - tanΘ2)

Where

P is the real power in kW.

Θ1 is the angle corresponding to the initial power factor.

Θ2 is the angle corresponding to the desired power factor.

Once the reactive power is determined, the excitation of the synchronous motor can be adjusted to supply the required leading reactive power to achieve the desired power factor.

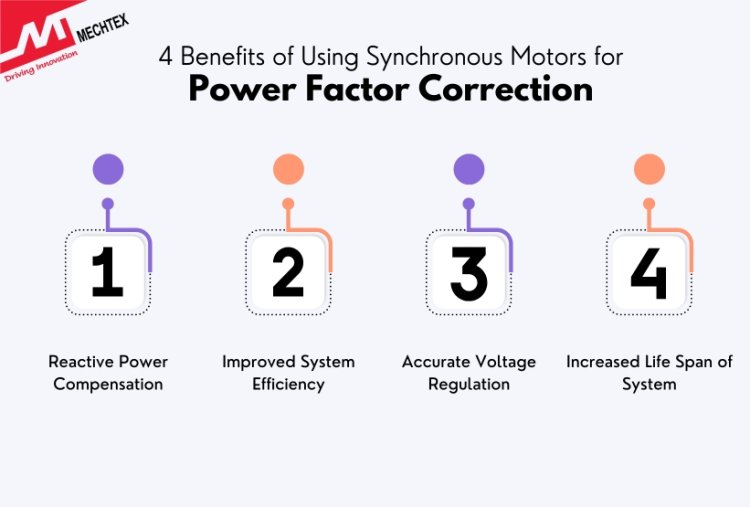

Benefits of Using Synchronous Motors for Power Factor Correction

Synchronous motors are widely used for power factor correction due to their unique ability to improve the efficiency of the system. Here are some key benefits:

- Reactive Power Compensation

Synchronous motors can operate at a leading power factor by over-exciting the field windings. This allows to supply reactive power to the system, reduces the load on the other equipment, and improves the overall power factor.

- Improved System Efficiency

A high power factor reduces the current drawn from the supply, which leads to low power losses and enhances the overall efficiency of the system.

- Voltage Regulation

Synchronous motors offer voltage regulation by controlling reactive power in the system. When the synchronous motor operates at a leading or lagging power factor, it adjusts reactive power flow and stabilises the voltage fluctuation. This balancing reduces the load on the voltage regulators and improves overall system efficiency.

- Increased Life Span of System

The synchronous motor corrects the power factor by reducing reactive power and minimising energy losses in electrical systems. This leads to low heat generation and prevents excess thermal stress. With less heat, the risk of breakdown and component degradation decreases and increases the lifespan of the system.

Conclusion

Power factor correction is essential for optimising electrical systems, reducing losses, and avoiding penalties from utility companies. Synchronous motors, with their ability to operate at a leading power factor, offer an effective solution for power factor correction. By adjusting the excitation of the motor, reactive power can be supplied or absorbed as needed, ensuring a more efficient and cost-effective operation.

In industrial applications, synchronous motors not only perform mechanical tasks but also serve as reliable tools for improving power quality. With their flexibility, stability, and energy efficiency, synchronous motors are a valuable asset in achieving power factor correction, especially in large-scale operations.

Understanding how synchronous motors contribute to power factor correction enables industries to make informed decisions about their energy management strategies, leading to significant cost savings and improved system performance.