Advantages and Disadvantages of Hybrid Stepper Motors (NEMA)

Common advantages of hybrid stepper motors include high torque, accurate positioning, smooth movement, and energy efficiency. However, they also have some drawbacks like higher cost, more noise and vibration, and the need for complex control systems amongst others.

What is a Hybrid Stepper Motor?

A hybrid stepper motor is a stepper motor that contains features of both a permanent magnet stepper motor and a variable reluctance stepper motor. It offers a balance between the torque and resolution. A hybrid stepper motor consists of a stator and rotor. The stator consists of multiple winding wounds around its teeth, while the rotor contains the permanent magnet providing a strong magnetic field.

It has a hybrid design which allows the advantages of both the PM stepper motor and the variable reluctance motor. Permanent magnets in the rotor create a strong magnetic field, resulting in high torque capabilities. This magnetism reduces power consumption and heat generation and increases the efficiency of hybrid stepper motors. Additionally, teeth on the rotor provide mechanical interference for precise movement.

On the other hand, stator winding enables fine control over the rotor's position. By energizing these windings in proper sequence, a rotating magnetic field is created, and interacts with the rotor's magnetic field, and generates movement. This working principle allows step-by-step movements of hybrid stepper motors with accurate positioning making them ideal for applications requiring high precision.

Hybrid stepper motors find their uses in robotics, CNC machines, 3D printers, medical equipment, and many other fields where precise control is essential. Their ability to deliver high torque and fine resolution makes them a preferred choice for applications where efficiency and accuracy are necessary.

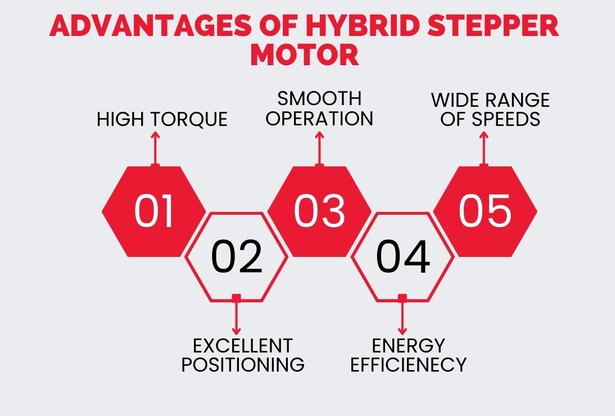

Advantages of Hybrid Stepper Motor

Hybrid stepper motors offer several advantages over other types of stepper motors, such as high torque, accurate positioning, smooth operation, and excellent efficiency making them a popular choice for many applications.

Let's take a look at the advantages of hybrid stepper motors:

- High Torque

Hybrid stepper motor consists of permanent magnet and stator winding. The stator winding is energized in a precise manner and generates a magnetic field.

This magnetic field interacts with the permanent magnet of the rotor creating high torque and allowing the rotor to move in discrete steps. This makes a hybrid stepper motor suitable for applications that require precise control over movement at higher loads.

- Excellent Positioning

Hybrid stepper motors use micro-stepping modes which involve dividing full steps into small micro-steps.

By controlling the current in each winding between full steps, the micro-stepping mode enables the motor for smooth movement. This fine control over the movement enhances the hybrid stepper motor's ability and enables them to hold their positions. This makes them ideal for applications such as robotics, CNC machines, and 3D printers, where precise positioning and control over movement are essential.

Mechtex Nema 23 Stepper Motor is a versatile and robust stepper motor. With holding torques ranging from 19 Ncm to 47 Ncm which makes it suitable for industries such as Medical and industrial Machinery.

- Smooth Operation

Hybrid stepper motors have a precise mechanical design. These motors consist of a rotor with teeth and a stator with winding. The interaction between the rotor teeth and stator winding provides a reliable mechanical interface and contributes to smooth operation.

This smoothness in operation is beneficial for applications where vibration and noise are minimal, such as in medical equipment or laboratory instruments.

- Energy Efficiency

Hybrid stepper motors are more energy efficient than other stepper motors due to the permanent magnet available in the rotor. This permanent magnet creates a magnetic field without the need for continuous energizing.

Unlike other stepper motors, that rely on continuous current supply to energize windings, hybrid stepper motors have inherent magnetism that generates torque. As a result, they consume less energy and become energy efficient. This energy efficiency can lead to cost savings and long life span, particularly in applications that require continuous operation.

- Wide Range of Speeds

Hybrid stepper motors operate at a wide range of speeds due to their precise control mechanism. By adjusting the sequence and timing of the current to the stator winding, hybrid stepper motors finely regulate their speed.

This precise control allows them to transit from low speed to high speed easily. This versatility makes them suitable for various applications across different industries.

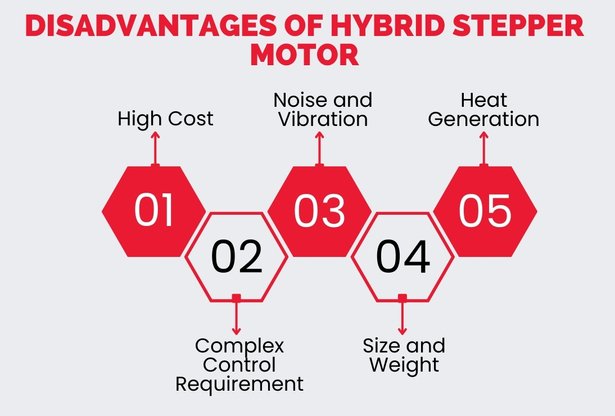

Disadvantages of Hybrid Stepper Motor

Hybrid stepper motors have certain disadvantages such as high cost, complex control systems, and noise and vibration that should be considered when selecting a hybrid stepper motor for a particular application.

Let's take a look at the disadvantages of hybrid stepper motors:

- Cost

Hybrid stepper motors tend to be more expensive than other types of stepper motors due to their complex construction. Unlike other stepper motor designs, hybrid stepper motors consist of permanent magnet and multiple-phase winding.

This complex design requires a highly specialized manufacturing process and high-quality materials which lead to higher production costs. Additionally, this complex design requires precision machining and assembly techniques which priced hybrid stepper motors high in cost as compared to other motors.

- Complex Control Requirement

Hybrid stepper motors require complex control algorithms due to their variable reluctance design. Unlike other stepper motors, hybrid stepper motors have a variable reluctance rotor-stator arrangement. It leads to non-linear torque-speed characteristics. To optimize the performance, it requires complex control algorithms to adjust current pulses to the windings based on load conditions, speed variations, and rotor position.

Consequently, control algorithms for hybrid stepper motors need to be sophisticated, and capable of effectively managing desired speed and torque performance levels in applications such as CNC machining and robotics.

- Higher Noise and Vibration

Hybrid stepper motors may produce more noise and vibrations during operation compared to other stepper motor types due to their micro-stepping technique. Microstepping enhances smoothness and resolution in movement, it can also increase noise and vibrations.

Microstepping involves dividing each full step into smaller micro-steps, which may result in higher frequency vibrations that can be audible in the system and affect the performance of the application.

Mechtex Nema 17 Motor produces less noise during the operation and improves the efficiency of the application.

- Size and Weight

Hybrid stepper motors are larger and heavier than other types of stepper motors due to the permanent magnet. This magnet is found in the rotor and used for generating the magnetic field required for movement.

The presence of the permanent magnet adds weight to the motor and increases the overall mass of the motor. As a result, hybrid stepper motors tend to be larger and heavier, and less suitable for applications where size and weight are constraints.

- Heat Generation

Hybrid stepper motors generate more heat as compared to other types of stepper motors during operation, especially at high speeds or when operating under heavy loads. This excessive heat buildup can reduce efficiency and reduce the lifespan of the motor. , Additionally, it requires cooling measures or thermal management systems to manage heat generation.

Also Read

Conclusion

Hybrid stepper motors have some great advantages like high torque, accurate positioning, smooth movement, energy efficiency, and the ability to run at different speeds. However, they also have some drawbacks like higher cost, complex control systems needed, more noise and vibration, larger size and weight, and excessive heat generation.

When deciding if hybrid stepper motors are right for you, think about what's most important for your specific use. If you need high precision, reliability, and energy efficiency, the advantages may be worth it. But if cost is the biggest factor and accurate positioning isn't needed, a different type of motor may work better. Carefully consider the good points and the bad points to make sure hybrid stepper motors fit your needs or not.