Construction of Synchronous Motor: Stator, Rotor & Field Excitation Explained

A complete guide to synchronous motor construction from the laminated stator and field-excited rotor to exciters, bearings, and how the design enables constant speed operation.

What is a Synchronous Motor?

A synchronous motor is an AC motor that operates at synchronised speed with the frequency of the AC supply. This means that a synchronous motor runs at a constant speed, which is determined by the frequency of the power supply and the number of poles in the motor. This characteristic distinguishes synchronous motors from induction motors.

In an induction motor, a slip occurs because the rotor of the induction motor can’t rotate along the magnetic field of the stator and does not ensure constant speed. However, in the synchronous motor, there is no slip.

It means the rotor rotates along with the magnetic field of the stator which ensures precise and constant speed throughout the operation. This magnetic field is known as RMF(Rotating Magnetic Field) which is created by applying the AC supply to the stator winding and the rotor rotates at synchronous speed along with RMF.

The synchronous speed (Ns) of the rotor can be calculated with the following formula:

Ns = 120 x ƒ/P

where

ƒ is the supply frequency in Hz

P is the number of poles.

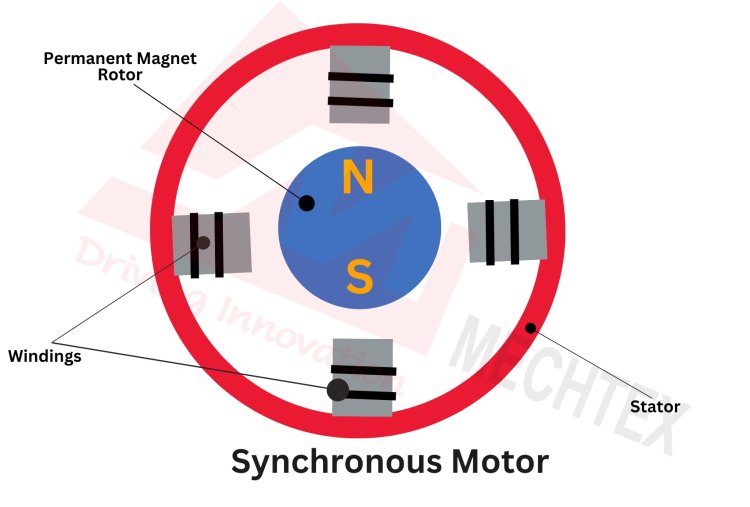

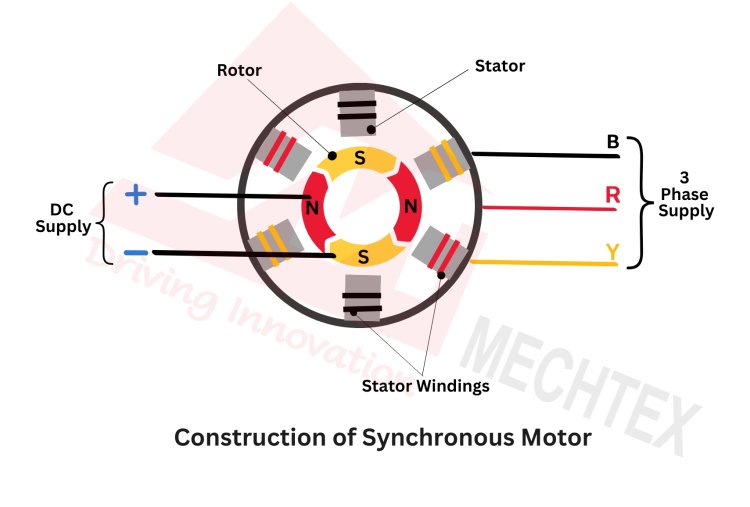

The construction of a synchronous motor includes a stator and rotor. The stator of a synchronous motor is similar to an induction motor consisting of laminated iron core windings with an AC supply. However, the rotor is the rotating part of the synchronous motor. It contains permanent magnets to create a constant magnetic field.

When synchronous motors start, the rotating magnetic field of the stator exerts torque on the rotor and causes the rotor to rotate. However, when a synchronous motor is ideal, the torque exerted by the stator causes the rotor to accelerate until its speed matches the synchronous speed of the stator.

After reaching the synchronous speed, the rotor locks its position with the RMF (Rotating Magnetic Field) of the stator and maintains synchronous speed throughout the operation regardless of load. However, synchronous motors are not self-starting. They require a separate starting mechanism because this motor cannot achieve synchronous speed on its own.

Also Read

Why Synchronous Motor is not Self-Starting

Synchronous motors offer several advantages over other AC motors. Synchronous motors run at synchronous speed under various loads and offer high efficiency, especially in high-load conditions. Synchronous motors also improve the power factor which enhances overall system efficiency and can reduce maintenance costs.

Additionally, the absence of slip makes synchronous motors highly efficient as they convert all electrical supply into mechanical power and result in minimal energy loss.

Synchronous motors are used in a wide range of applications where precise speed is essential such as robotics, conveyor systems, and clocks. This AC motor also found its use in applications requiring high efficiency and power factor correction such as industrial drives.

Construction of Synchronous Motor

The construction of a synchronous motor involves several key components such as stator, rotor, bearing, and exciter. Each component plays a crucial role in the working of a synchronous motor.

Some of the main components of the synchronous motors are:

- Stator

The stator is the stationary part of the synchronous motor. It consists of an iron core made up of laminated steel to reduce current loss. This core consists of three-phase windings to create RMF (rotating magnetic field). When these windings are energised with AC supply, they create a rotating magnetic field which interacts with the rotor and creates motion.

- Rotor

The rotor is the rotating part of the synchronous motor. It can be of two types: salient pole and non-salient pole. The salient pole rotor has poles which are placed around the rotor. Each pole has a winding and creates a magnetic field. A non-salient pole rotor is a cylindrical rotor consisting of a laminated steel sheet with a smooth surface and is found especially in high-speed motors.

- Exciter

It provides DC current supply to the rotor winding to create a magnetic field that interacts with the stator winding and causes motion. The DC current can be supplied either through slip rings and brushes or through a brushless excitation system.

Other Components

- Bearings

Bearings are placed at both ends of the shaft. It provides support to the rotor and allows it to rotate smoothly with the stator's magnetic field.

- End Bells

The end bells enclose the stator and rotor. They are mounted on both sides of the synchronous motor. They provide support to the shaft of the motor and housing to the bearings.

Working Principle of Synchronous Motor

Synchronous motor operates on the principle of electromagnetic induction. When AC voltage is supplied to the stator windings, it creates RMF (Rotating Magnetic Field). The rotor contains a permanent magnet that is excited by the DC supply, creates a constant magnetic field and interacts with the rotating magnetic field of the stator.

Due to this interaction, the rotor aligns itself with the RMF (Rotating Magnetic Field) and rotates at synchronous speed. It means the rotor does not experience slip, unlike the induction motor. Therefore, these AC motors are highly efficient and provide reactive power to electrical systems that help in energy consumption.

Also Read

Working Principle of Synchronous Motor

Applications of Synchronous Motor

Synchronous motors are used in a wide range of applications where precise speed, high efficiency and power factor correction are required.

Here are some common applications of synchronous motors:

- Industrial Drives

Synchronous motors are used in various industrial drives such as compressors, pumps, and conveyor systems where constant speed is necessary.

- HVAC Systems

Synchronous motors are used in HVAC systems to drive fans and blowers with precise speed to ensure regular flow to temperature.

- Textile Machines

Synchronous motors are used in spinning machines, conning machines and weaving looms where precise speed control is required for operation.

- Pumps

Synchronous motors are used in various types of pumps which require constant speed operation, especially in water and chemical processing units.

- Gastronomy

Synchronous motors are used in various gastronomy equipment such as blenders, ovens, automated beverage dispensing machines and packaging machines to ensure reliable performance.

Also Read

Applications of Synchronous Motor