How Hall Effect Sensors Work in BLDC Motors: Position Detection & Commutation

An ESC (Electronic Speed Controller) is an electronic device used to control speed, direction and braking of the electric motor. Learn how Hall effect sensors detect rotor position in BLDC motors to enable precise commutation, improve startup and low-speed performance, and support smooth, efficient operation.

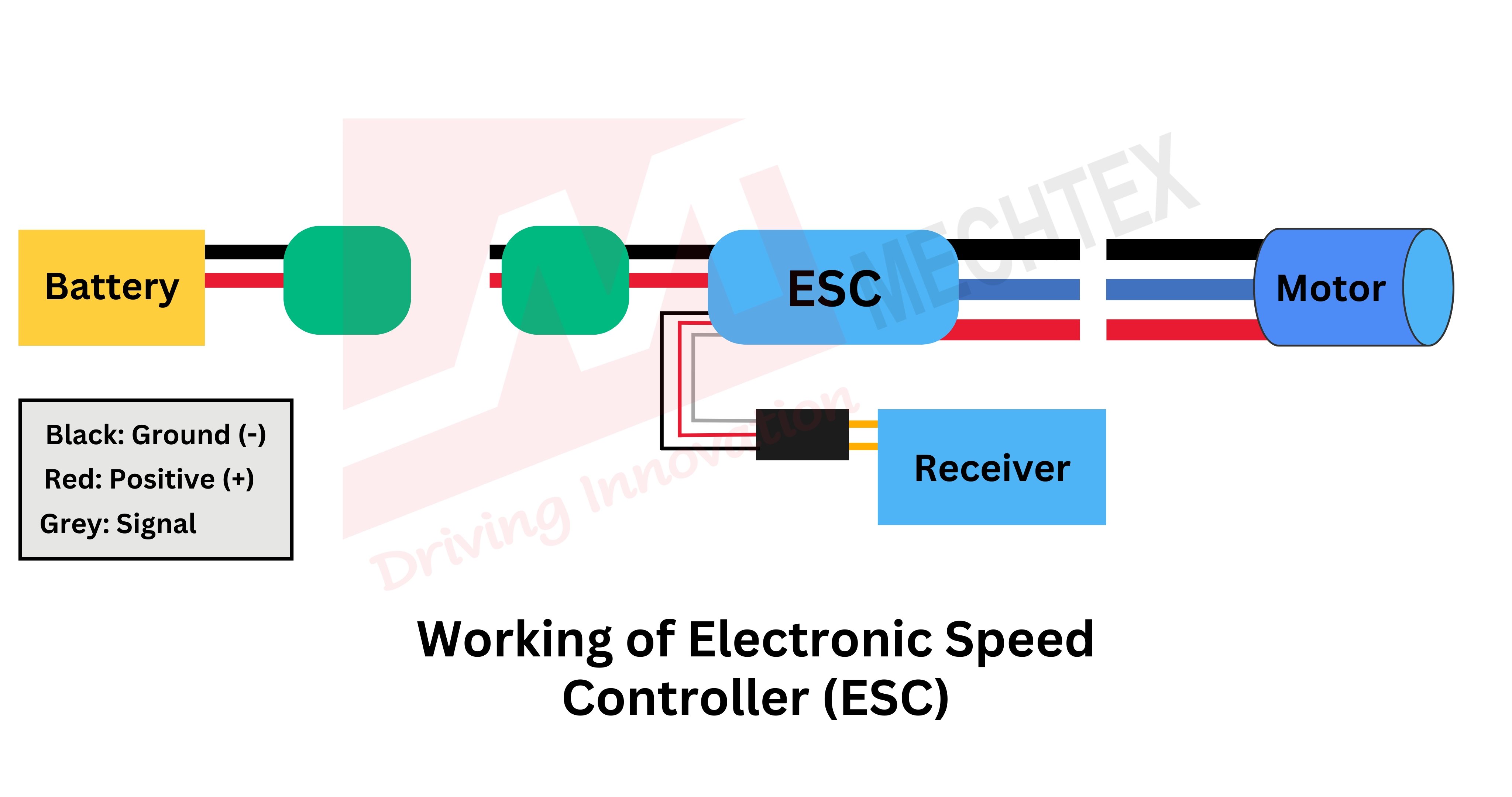

In the modern era of electromechanical systems, application is not solely performed with the help of the motor itself. It requires control electronics that drive the motor for better performance. One of the most important components in the control electronics is the Electronic Speed Controller (ESC).

ESC works as an interface between the power source and motor. It also helps to control various parameters such as speed, direction, braking and others. However, not all ESCs are the same. Different types of motors require different ESCs with specific designs and control strategies.

In this blog, we will explore the relationship between ESC and different types of motors, and how they help the motor to control different parameters and their control strategies.

What Is an ESC?

An ESC (Electronic Speed Controller) is an electronic device used to control speed, direction and braking of the electric motor, especially BLDC Motor (Brushless DC Motor) and Brushed DC Motor.

It serves as a bridge between the power supply and the motor to achieve smooth and precise operation. It receives the throttle signal from the flight controller and adjusts the motor speed and direction accordingly. It allows for precise performance, which is essential for applications such as drones, electric vehicles, and robotics.

It also includes various features such as regenerative braking, easy start, and a protection mechanism against overcurrent, undervoltage and overheating.

Overall, ESCs are not just speed controllers but a control system that improves the efficiency, responsiveness and performance of the electric motor.

Motor Types and Their Requirements

Different types of motors have different electrical commutation systems for smooth and efficient performance. It directly affects the design and requirements of ESC.

Below are some main categories of electric motors and their ESC requirements.

Brushed DC Motors

Brushed DC motor is an electric motor that converts direct current into mechanical rotation using brushes and commutators. The brush transfers the current to the rotor and creates a magnetic field to produce rotation.

These motors are simple in design, low-cost, and easy to control, which makes them suitable for applications like toys, power tools, and automation systems.

A brushed DC motor needs an ESC to regulate the power from the source to the motor. Without an ESC, the brushed DC motor would run at full speed with no control.

The ESC helps in speed control, direction reversal, and provides protection features which make brushed DC motors more efficient and responsive.

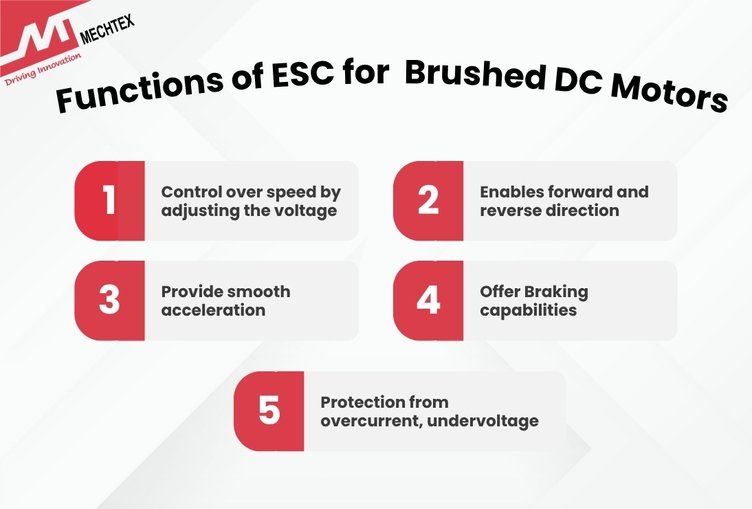

Functions of ESC for Brushed DC Motors

- Control over speed by adjusting the voltage and current applied.

- Enables forward and reverse direction by switching polarity.

- Provide smooth acceleration and deceleration.

- Offer Braking capabilities for better control.

- Protect the brushed DC motor and circuit from overcurrent, undervoltage and other.

Control Method

Brushed DC motors use a brushed ESC for commutation. Brushed ESC with pulse width modulation (PWM) help to regulate the speed.

By varying the duty cycle of the PWM signal, the ESC control the voltage applied to the motor. Direction control is achieved by reversing polarity through an H-Bridge circuit.

Brushless DC Motor

BLDC motor is an electric motor which converts direct current into mechanical motion without using brushes. It uses electronic commutation through ESC and a position feedback system.

It offers high efficiency, low maintenance, and precise speed control, making it ideal for drones, robots, EVs and other applications.

A BLDC motor requires an ESC to electronically commutate by energising the correct stator windings and synchronise with the rotor for smooth rotation.

Functions of ESC for BLDC Motors

- Perform electronic commutation by switching the current in the right sequence.

- Control motor speed and torque through PWM signals.

- Ensure a smooth start and acceleration.

- Optimise efficiency and performance across various load conditions.

Control Method

ESC use for BLDC motor has Pulse Width Modulation (PWM signal) along with electronic commutation. Based on the rotor’s position, the ESC energises the correct phase and creates a rotating magnetic field. Varying PWM signals help to adjust the speed, direction and torque of the BLDC motor.

Stepper Motors

Stepper motor is an electromechanical device which converts electrical pulses into precise movements. It rotates at a fixed angle, which allows for accurate positioning without any feedback system.

Stepper motors are reliable and have excellent repeatability, ideal for CNC machines and 3D printers.

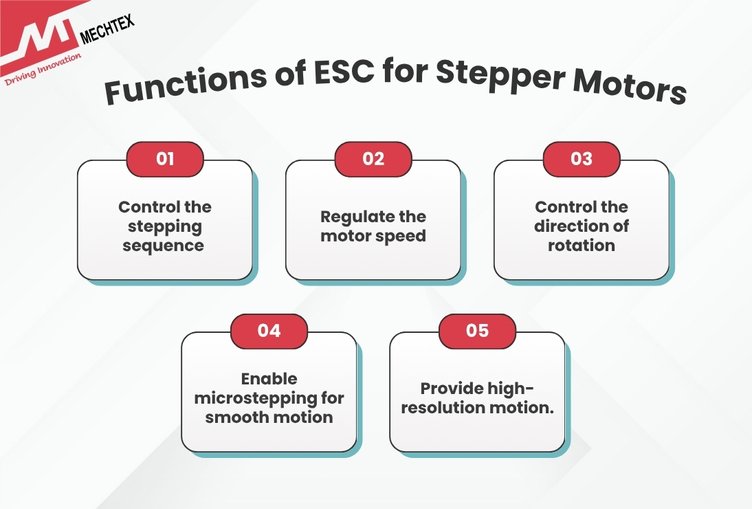

Functions of ESC for Stepper Motors

- Control the stepping sequence and phase windings.

- Regulate motor speed by adjusting pulse frequency.

- Control the direction of rotation.

- Enable microstepping for smooth and high-resolution motion.

Control Method

ESCs or drivers used in stepper motors have pulse signal control rather than PWM signals. Each pulse sent to the driver corresponds to every step. The pulses also determine speed, energising sequence determines directions. This allows precise and stable movement without any feedback system.

Conclusion

The relationship between ESCs and motor types is fundamental to modern electromechanical systems. Brushed DC motors rely on simple ESCs for voltage control, BLDC motors depend on advanced ESCs for electronic commutation, and stepper motors use specialised drivers for pulse sequencing.

Choosing the right ESC involves understanding motor characteristics, control strategies, and application needs.

Whether it’s drones, EVs, or industrial automation, the right ESC-motor pairing is the key to unlocking optimal performance.