Optical Encoders: A Comprehensive Guide

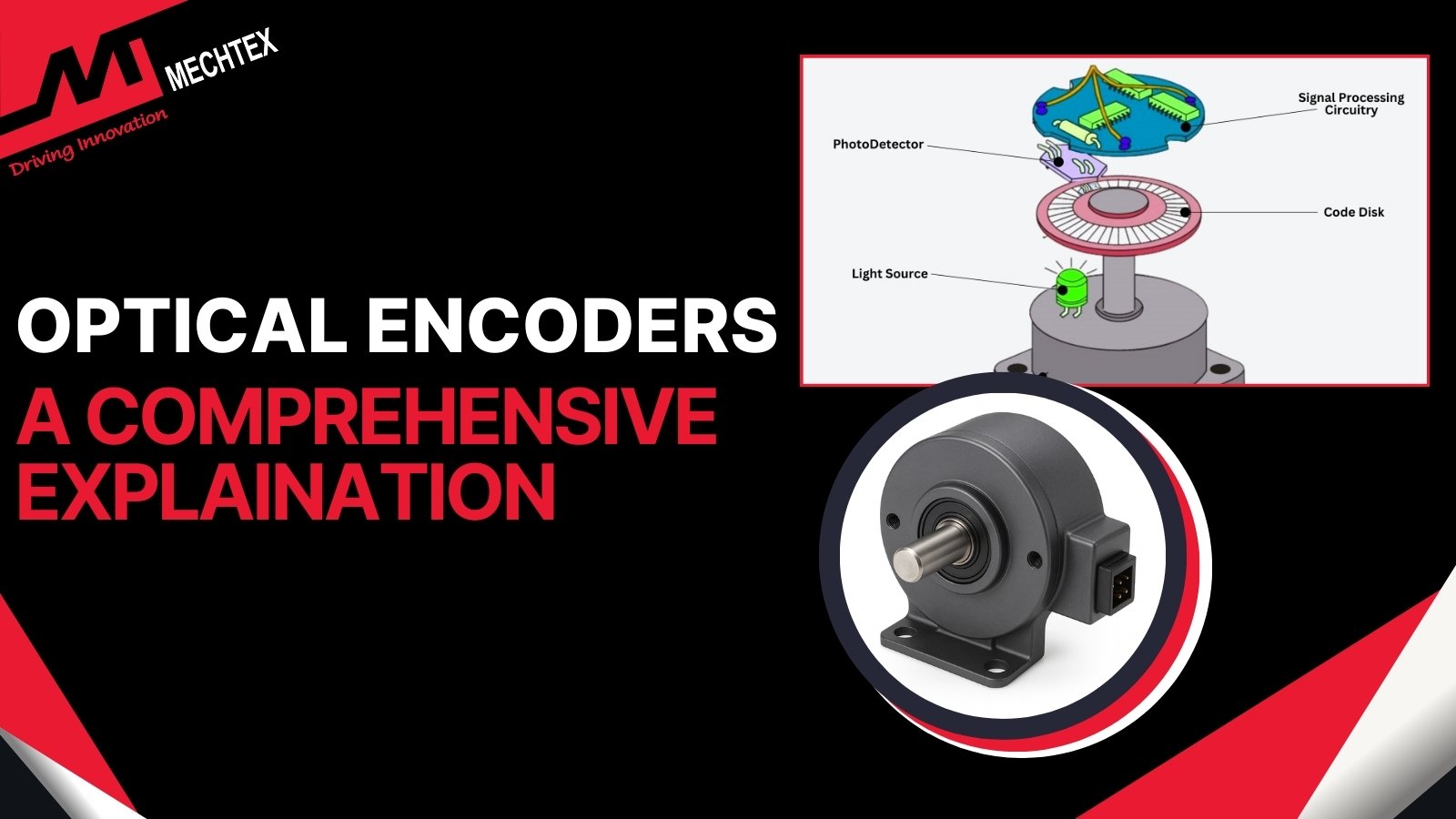

An optical encoder is an electromechanical device used to convert the angular position of a shaft into electrical signals. Its main components include a light source, a code disk, a detector and signal processing circuitry. It works on the principle of light interruption and reflection.

In the modern automation world of robotics and motion control systems, accurate positioning and feedback are essential for achieving precision and accuracy in operation.

One of the most commonly used feedback devices used to achieve precision and accuracy is the optical encoder.

These encoders translate the motion into electrical signals and enable machinery to operate with precision.

In this blog, we will study what optical encoders are, their working principles, and their applications.

What is an Optical Encoder?

An optical encoder is an electromechanical device used to convert the angular position of a shaft into electrical signals for accuracy. It operates on the principle of light interruption and detection, which offers precise positioning and accurate feedback.

Unlike other types of encoders, optical encoders are known for their reliability and resolution and making them a preferred choice for modern applications.

Watch the YouTube Video by "Wisc-Online" about optical encoders

An optical encoder measures the movement of the object or shaft and converts it into electrical signals that can be interpreted by control systems.

These signals provide data about the position, speed and direction of the object for enhanced performance of the system.

Optical encoders are valued for their ability to deliver accurate results in both simple and advanced control systems. They are crucial components for modern automation, robotics and other control systems to ensure efficient and accurate operations.

By offering a perfect blend of precision and resolution, optical encoders bridge the gap between mechanical motion and digital signals.

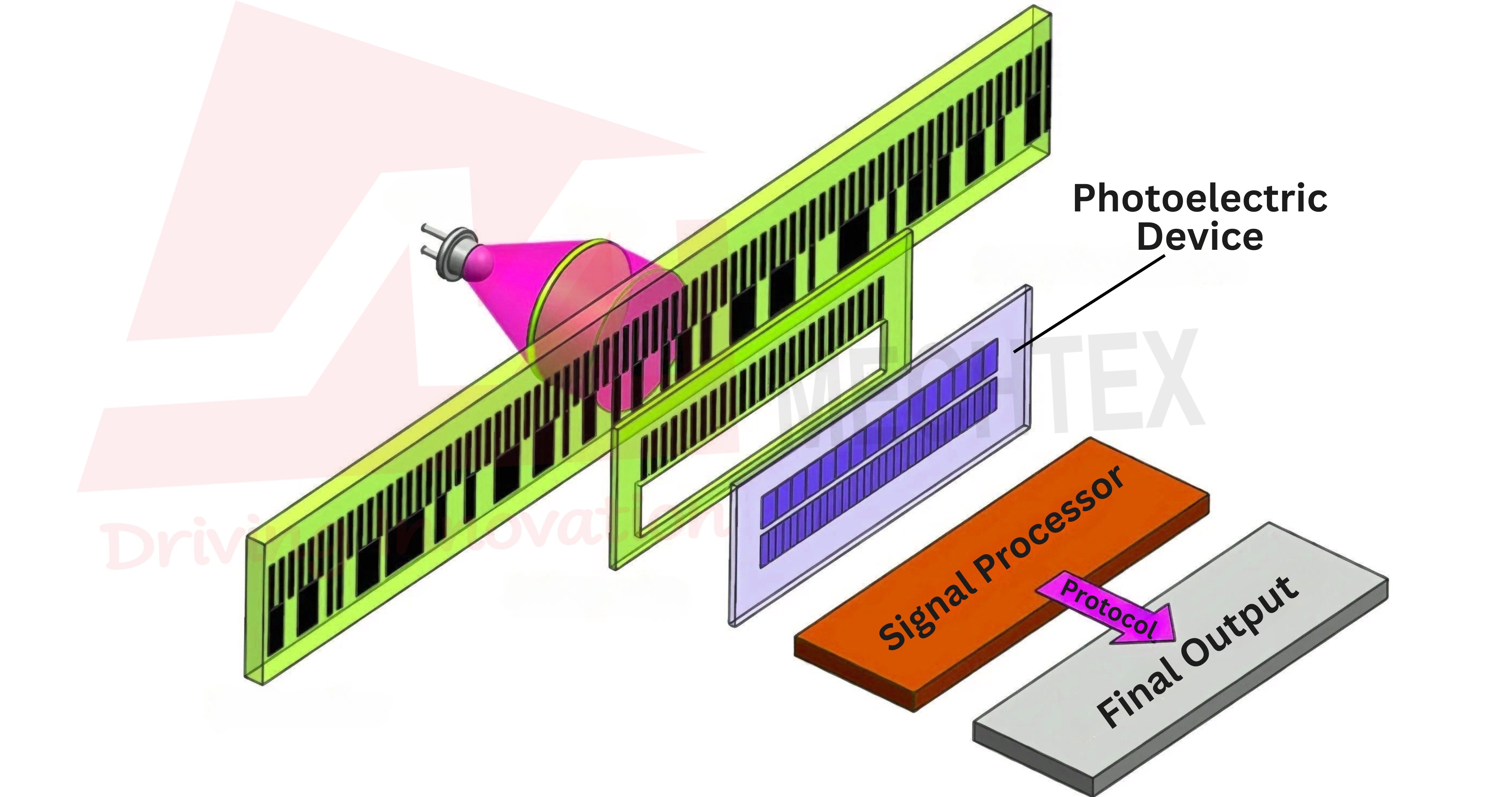

Construction of Optical Encoders

The construction of the optical encoder is centered around the use of light, which acts as a medium to detect the position of an object.

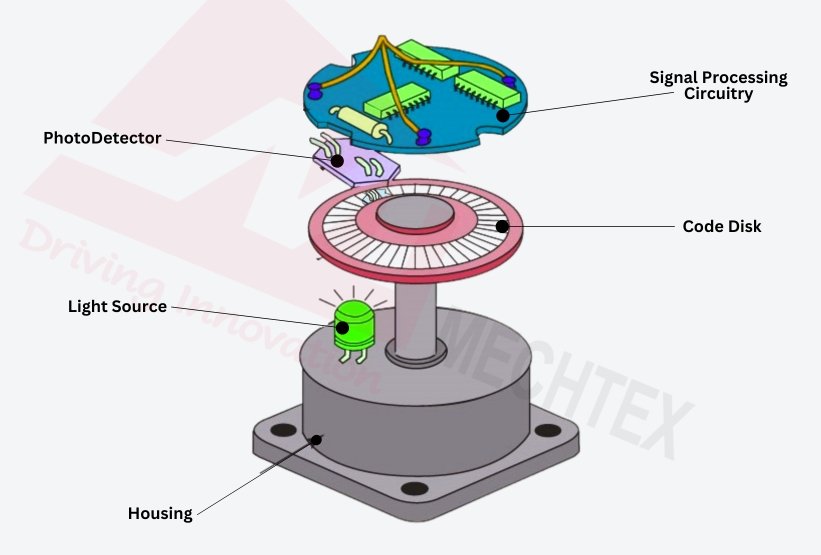

Its main components include a light source, a code disk, a detector and signal processing circuitry. Each element works together to convert mechanical movements into electrical signals for high accuracy. Construction of an optical encoder includes:

- Light Source

In an optical encoder, a light-emitting diode (LED) is used as a source of light. This LED releases a focused beam that passes through or reflects off the code disk to create digital signals.

- Code Disk

It is the core element of the optical encoder. It is a transparent disk made up of glass and plastic with alternating segments. This segment divides the rotation of the object into distinct intervals for better resolution.

The resolution depends upon how many segments are present on the disk. The higher the number of segments, means more resolution it provides.

- Detector

It consists of photodiodes and a phototransistor and is placed near or opposite to the light source.

When the LED passes through the transparent section of the disk, the detector detects the light and generates electrical signals.

Inversely, when the LED do not pass through the opaque segments, no signal is generated. This alternating pattern produces digital pulses for accurate information.

- Signal Processing Circuitry

It processes the raw signals from the detector into square wave pulses. Additional electronics refine the signals, reduce noise, and provide different outputs for better results.

Working of Optical Encoders

The working of an optical encoder is based on the principle of light interruption and reflection to sense the motion and convert it into electrical signals.

It translates the movement of the shaft into digital pulses with the help of a control system for accurate feedback.

This process begins with an LED which emits a steady beam of light. It directs towards a disk which consists of alternating transparent and opaque segments.

As the shaft connects with the encoders. When the shaft moves or rotates, the disk moves along with it and periodically blocks and allows the light.

On the other side of the disk, the photodetector is placed to sense the light. Whenever the light passes through the transparent segment of the disk, the photodetector produces a signal or pulses to provide feedback.

By counting the pulses or signals, the system determines position and distance. The pulse frequency indicates the speed, while using multiple detectors with a phase shift allows the encoder to determine the direction of motion.

Finally, the raw signals from the photodetector are processed through an electronics circuit to convert them into a square wave output.

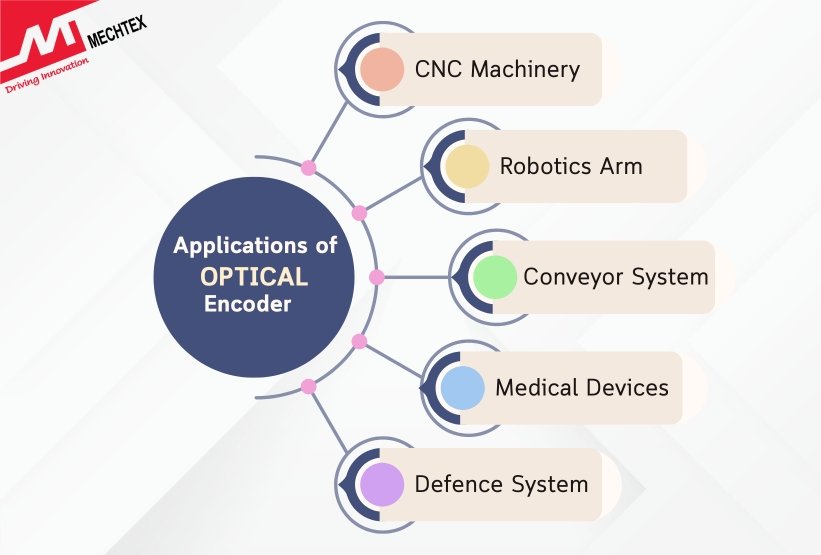

Applications of Optical Encoders

Optical encoders are widely used in industries due to their high precision, reliability, and accurate position feedback. The list of applications of optical encoders is:

- CNC Machinery

In this application, the encoders provide precise positioning and speed feedback to ensure accurate cutting, milling, and assembly operations. It helps to maintain tolerance and improve productivity.

- Robotics

In robotics, optical encoders play a crucial role in guiding movement and ensuring the accurate positioning of arms for pick and place. It enables smooth navigation and precise control, which is vital for various tasks.

- Conveyor Industry

In this Industry, the optical encoder ensures smooth control, reliable positioning and safety by enhancing the movements of the conveyor belt.

Beyond industrial use, optical encoders find applications in medical devices, such as imaging systems and surgical robots, where high-resolution feedback ensures accuracy and safety. They are also used in aerospace and defence systems for navigation and control.

Conclusion

Optical encoders play a pivotal role in enabling precision across industries such as robotics, CNC machinery, aerospace, and automation.

By converting motion into accurate electrical signals, they allow machines to operate with remarkable efficiency and control.

While they have limitations in harsh environments, their unmatched accuracy ensures they remain the preferred choice in applications demanding precision.

As technology advances, optical encoders are becoming smarter, smaller, and more versatile, making them indispensable for the future of motion control and automation.