What is Hybrid Stepper Motor

A hybrid stepper motor rotates by transforming a sequence of electrical pulses into exact angles, or steps. The design and benefits of both permanent magnet type and variable reluctance type stepper motors are essentially combined in a hybrid stepping motor.

"Hybrid stepper motors offer the perfect blend of precision and power, to drive innovation in automation"

Ever wondered how 3D printers, robots, and other cool gadgets move so precisely? The secret lies in a special kind of motor called hybrid stepper motor. Hybrid stepper motors are like the driving force of motion control, seamless operation of CNC machines, 3D printers, robotic arms, and more with precise movements.

In this blog, we will explore the magic behind the hybrid stepper motor.

What is a Hybrid Stepper Motor?

Hybrid Stepper Motor is a type of electric motor that converts digital pulses into precise movements. It is a type of stepper motor that combines the features of both permanent magnet stepper motor and variable reluctance stepper motor and offers exceptional performance with versatility.

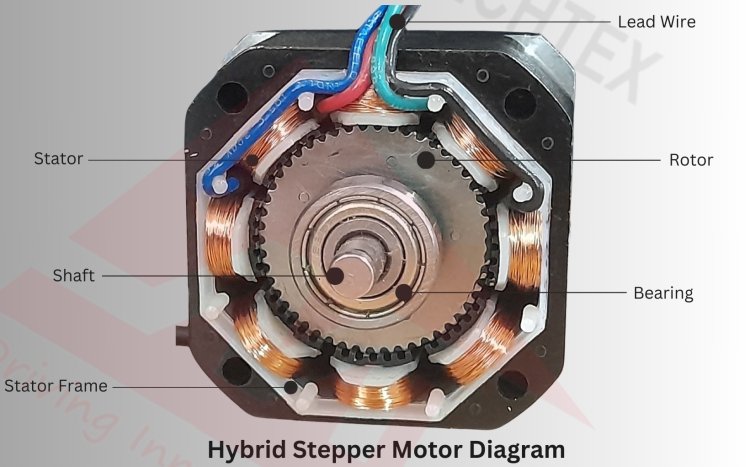

A hybrid stepper motor consists of three main components such as stator, rotor, and driver. The stator is the stationary part of the motor. It consists of a series of electromagnets arranged in a specific pattern. While the rotor is the rotating part of the motor and consists of permanent magnets. The driver provides electrical pulses to the stator and controls the movement of the motor.

Watch a visual representation of the basics of the hybrid stepper in the video posted by "The Engineering Mindset"

A hybrid stepper motor operates at the principle of electromagnetic induction. When the electrical pulse is applied through the driver to the electromagnets of the stator, it creates a magnetic field. This magnetic field interacts with the permanent magnet of the rotor and causes it to rotate at a specific angle.

Hybrid Stepper Motor offers several advantages as compared to other type of stepper motor. The fact that the rotor of a hybrid stepper motor stays locked in place even after the excitation is removed is one of its primary benefits. The detent torque generated by the permanent magnet is the reason behind this.

Hybrid stepper motors also provide precise control over the movement of the motor and allow the motor to move at a precise angle. These stepper motors provide high torque as compared to other motors, making them suitable for applications that require high starting torque such as CNC machines.

Another advantage of hybrid stepper motors is their versatility. These motors are compatible with various control systems and are used in a wide range of applications. Hybrid stepper motors find their uses in various applications such as Medical equipment, Industrial automation, Robotics, and Consumer electronics.

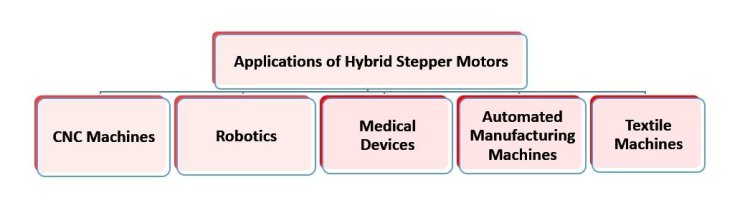

Applications of Hybrid Stepper Motor

Hybrid stepper motors offer precise control, high torque, and versatility in their operation. These features make them a preferred choice for a wide range of applications across various industries.

Here are some common applications of hybrid stepper motors

- CNC Machines

Hybrid stepper motors are integral components of CNC machines by facilitate precise positioning and accurate movement in manufacturing processes such as milling, routing, cutting, and drilling. NEMA 17 hybrid stepper motors are commonly used in CNC machines due to their compact size, high torque output, and reliability, ensuring consistent and accurate operations during complex machining tasks.

- Robotics

Hybrid stepper motors are indispensable components in robotics by offering precise control and accurate movement in various robotics applications. These stepper motors are commonly used in actuating joints in robotics arms by providing the accuracy required for intricate movements.

Hybrid stepper motors also find their use in positioning sensory equipment allowing robots to perceive and interact with surroundings. These stepper motors are also used in industrial grippers to pick and place objects in different places.

- Medical Devices

Hybrid stepper motors play a pivotal role by ensuring precision and accuracy in various medical devices. These stepper motors ability to hold the position with high resolution makes them ideal for drug delivery systems to precisely regulate the dosage of medicines.

These motors are also used in imaging systems such as CT Scanners and MRI machines by controlling the movement of the patient bed with exceptional accuracy. NEMA 23 hybrid stepper motors are often used in these applications for their higher torque and robustness, ensuring reliable performance in critical medical environments.

- Automated Manufacturing Process

Hybrid stepper motors play a crucial role in the automated manufacturing process by enabling precision and accuracy in movement. Their ability to precisely control positioning and movement makes them indispensable in applications such as robotic assembly lines, CNC machining centres, and 3D printing systems.

Furthermore, hybrid stepper motors are also employed in packaging and labelling lines, material handling systems, and quality control processes, where their precise control capability facilitates efficient and consistent operation.

- Textile Machinery

In weaving machines, these motors are used to control the intricate movements of looms and ensure accurate yarn positioning for creating consistent fabric patterns. Similarly, in knitting machines hybrid stepper motors control the position of needles and yarn carriers to enable complex stitching process and design.

Hybrid stepper motors are also used in textile printing and dyeing processes by facilitating the precise positioning of print heads and dyeing applicators resulting in accurate and repeatable colour patterns. NEMA 24 hybrid stepper motors are often used in these textile applications for their enhanced torque capacity and durability, making them ideal for demanding industrial environments.

Also Read:

Advantages and Disadvantages of Hybrid Stepper Motor

Construction of Hybrid Stepper Motor

The construction of a hybrid stepper motor involves various components that work together to enable its operation. The concepts of two motors, such as a permanent magnet & variable reluctance stepper motor, can be used to produce a hybrid stepper motor.

These stepper motors can be purchased without a gearbox and with various step resolutions, such as 0.9° and 1.8°.

Here is an overview of some major components of a hybrid stepper motor:

- Stator

It is the stationary part of the motor. It is the rigid structure that provides foundational support to the motor. It is made up of high-quality materials such as steel and aluminium to handle the mechanical stress during the operation. It consists of two main components:

Stator frame - It provides structural support to the motor and houses the other components of the stator.

Stator winding - It is the coils of winding wound around the poles of the stator. In a hybrid stepper motor, there are different sets of winding: one for a permanent magnet pole and another for a variable reluctance pole.

- Rotor

It is the rotating part of the stepper motor and is located inside the stator. It consists of two types of poles.

Permanent magnet poles: It is usually made of materials like neodymium iron boron (NdFeB). These poles generate a magnetic field.

Variable reluctance pole: It is made of magnetic material that can be magnetized temporarily by the stator windings. These poles are arranged in alternating patterns around the rotor. The permanent magnet pole provides a constant magnetic field that interacts with the changing magnetic field of the stator and creates a force for movement. After magnetising the stator winding, the variable reluctance pole enhances the magnetic force and allows for precise control and stepping movement.

- Shaft

It plays a crucial in the working of the stepper motor. It transmits the rotational motion generated by the rotor to external components. It involves a solid rade made up of durable materials and allows for coupling with other devices. Its extension outside the motor casing provides versatility and makes it connect with various mechanical systems.

- Bearings

It is a crucial component of a hybrid stepper motor. It supports and guides the shaft of motors for smooth operation within the rotor. It reduces the friction between the rotor shaft and motor casing for smooth and efficient operation.

- Endbells

They are positioned at both ends to enclose and safeguard the internal components of the hybrid stepper motor. It is made up of materials such as aluminium and steel to offer durability in various operating conditions. It provides structural support and provides alignment and stability to the stator and rotor for smooth and precise operation.

Working of Hybrid Stepper Motor

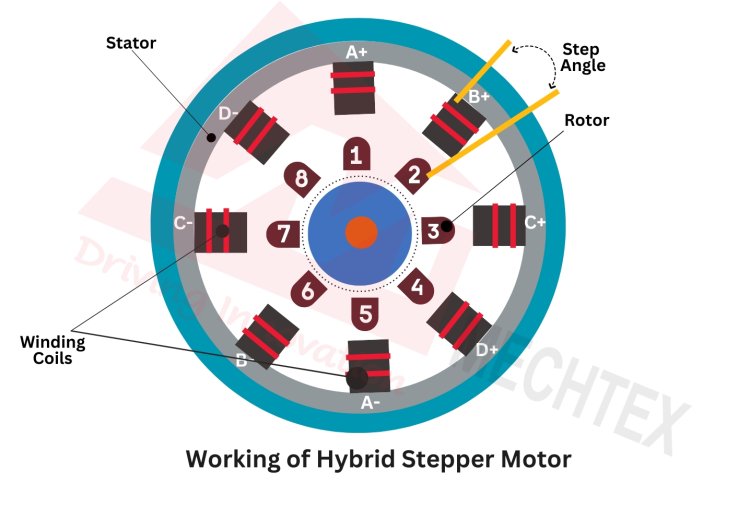

A hybrid stepper motor combines the features of both permanent magnet stepper motor and variable reluctance stepper motor. A hybrid stepper motor consists of a rotor with a permanent magnet with poles and a stator with windings around its pole. This winding is typically divided into two sets of effects: permanent magnet effect and variable reluctance effect.

When current flows through the winding of the stator, it creates a magnetic field. Then the rotor aligns itself with the path of the lowest reluctance of this magnetic field. This effect is called the variable reluctance effect. This effect allows a hybrid stepper motor for precise movements.

Simultaneously, the permanent magnet in the rotor provides a constant magnetic field. When stator windings are energised, they attract the teeth of the rotor toward the closest position of alignment. This effect is called the permanent magnet effect. It enhances the torque of a hybrid stepper motor, especially at high speed.

The combination of the permanent magnet effect and variable reluctance effect offers fine step resolution to hybrid stepper motors. The variable reluctance effect offers a large number of steps per revolution, while the PM effect ensures the accuracy and stability of the rotor position.

Therefore, the hybrid stepper motor's working principle involves the blend of permanent magnet and variable reluctance effects to provide precise movements and enhanced torque at high speeds.

Conclusion

Since hybrid stepper motors outperform permanent magnet motors in terms of holding torque, speed, and step resolution, hybrid stepper motors are very popular. However, these are also more costly than PM stepper motors. While permanent magnet or variable reluctance stepper motors are only suitable for specific applications, hybrid stepper motors are well suited for the majority of uses.

Also Read:

Working of Hybrid Stepper Motor