Comprehensive Guide on BLDC Motor | Introduction, Construction and Applications

A BLDC motor is a three-phase brushless DC electric motor powered by direct current. Unlike brushed DC motors that incorporate brushes, BLDC motors utilise a permanent magnet in the rotor. This offers several advantages which make them suitable for various industrial applications that require precision and efficiency in operation.

What is a BLDC Motor?

A BLDC motor is a three-phase brushless DC electric motor powered by direct current to produce rotational power within the rotor. The full form of the BLDC motor is brushless DC motor. Unlike brushed DC motors, which operate with the help of brushes that rub against each other to produce rotating power, This brushless DC motor uses a permanent magnet in the rotor for rotation.

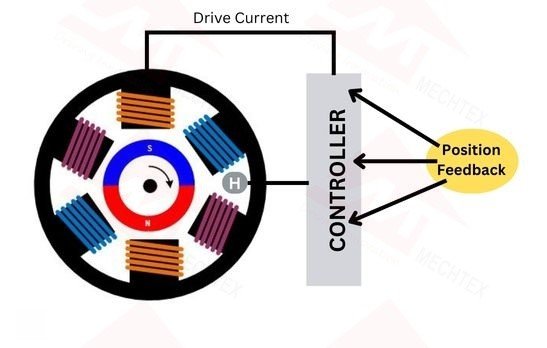

The primary components of BLDC motors are the stator and rotor. The stator is the stationary part of the motor and consists of coils. When these coils are energised with a DC supply in a specific sequence, it creates a magnetic field. The rotor is a rotating part of the motor and consists of permanent magnets. These magnets interact with the magnetic field produced by the stator which results in the rotation of the motor.

Unlike traditional brushed DC motors, which rely on brushes and commutators for their operation. In a BLDC Motor, the electronic controller sequentially energises the stator winding and creates a magnetic field. The rotors consist of permanent magnets that interact with the stator’s magnetic field and start rotating. The BLDC motor controller continuously adjusts the current in the stator’s winding based on the rotor’s position to ensure smooth and efficient operation. This precise control over the stator’s magnetic field and rotor’s position enables BLDC motors to operate without brushes and reduce friction, wear and tear.

One of the key advantages of BLDC motors is their high efficiency. As there are no brushes involved in the working of BLDC motors, it reduces frictional loss and increases the overall efficiency of the BLDC motors which makes them ideal for applications where energy consumption is a concern. Furthermore, BLDC Motors offers better speed control and a high torque torque-to-weight ratio as compared to brushed DC motors. From electric vehicles to HVAC systems and electronic devices, BLDC motors are used in diverse industries where precise motion control is required.

Construction of BLDC Motor

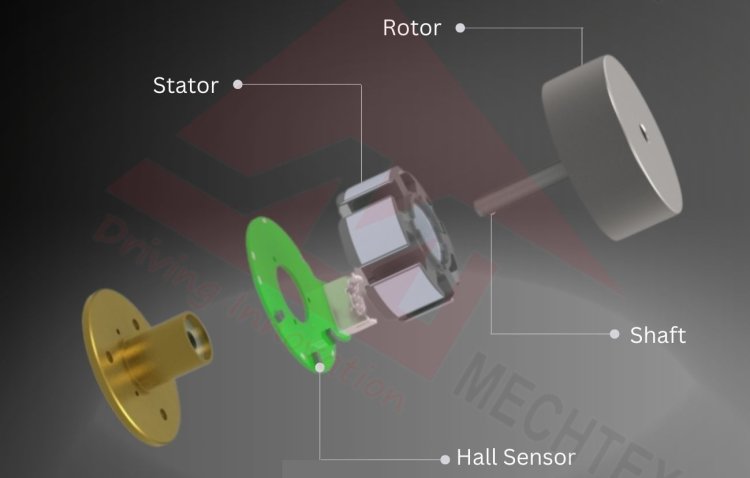

Construction of the BLDC motor includes stator, rotor, and hall sensors that work together to generate rotational motion.

Let's take a look at some important components of BLDC motors below:

- Stator

The stator is one of the most important components of BLDC motor construction. The stator produces magnetic force to rotate the rotor of the motor. It is either inside or surrounded by a rotor or enclosed close to the motor.

Stator windings are arranged in either a star or delta pattern. The star pattern produces high torque at low speed, while the delta pattern produces low torque at low speed.

- Rotor

The rotor is another important component of construction of BLDC motor. It made up of permanent magnets and provides a magnetic field to react with a stator for rotational movement. It consists of poles. The number of poles in the rotor may vary from 2 to 8. Increasing the number of poles provides better torque but reduces the speed of the motor.

- Position Sensor (Hall Sensor)

The majority of BLDC motors use Position Sensors (Hall sensors). Position Sensors (Hall Sensors) are usually placed in stator coils. It generates a voltage from a magnetic field. Then voltage is used to determine the field intensity.

It detects the position of the rotor and transforms it into electrical signals. Its output might be high or low depending on the north pole or south pole of the rotor. Most BLDC Motors use three hall sensors embedded into the stator to detect the rotor's positions

Other Components

Bearing - It supports the rotor and allows the smooth and efficient movement of the motor while reducing friction.

Shaft - It is the central component of the motor responsible for rotational movement. It connects the rotor with the application.

Casing - It protects the internal components of motors. It provides structural support and acts as a barrier to external environmental conditions.

Also Read

Working Principle of BLDC Motor

Advantages of BLDC Motor

Brushless DC (BLDC) motors offer several advantages over the brushed DC motor which makes them suitable for various industrial applications that require precision and efficiency in operation. Some of the key advantages are:

- High Efficiency

BLDC motors have high efficiency as compared to brushed DC motors because they do not have brushes to create friction and cause energy loss.

- Long Lifespan

Since BLDC motors do not have brushes and commutation for operation. It results in less wear and tear and increases the operational life.

- High Power Density

BLDC motors are designed to be more compact and lighter than brushed DC motors. It results in delivering a greater power output and is advantageous for various applications.

- Better Speed Control

BLDC motors provide precise speed and position control due to their electronic commutation method. This method allows for smooth operation and accurate operation of the BLDC motor.

- Quiet Operation

Without brushes that create friction, BLDC motors operate more quietly than traditional brushed DC motors. This makes them crucial for applications that require low-noise operations.

Disadvantages of BLDC Motor

Despite various advantages, BLDC motors have various disadvantages that restrict their uses in some industrial applications. Some of the disadvantages are:

- High Cost

BLDC motors have a high initial cost as compared to brushed DC motors due to the complex electronic control systems required for their operation.

- Complex Electronic Control System

BLDC motors require complex electronic controllers to manage the commutation and speed regulations. This adds complexity and cost to the overall system of BLDC motors.

- Limited Low-Speed Performance

BLDC motors exhibit low performance at low speeds especially, if the electronic controllers and other control algorithms are not well programmed. This can be a drawback in applications that require precise low-speed operation.

- Limited Torque

Depending upon the design and control algorithms, the BLDC motor might offer less torque output. This affects the smooth operation of the BLDC motor and becomes a major drawback for applications requiring smooth motion.

Also Read

Advantages and Disadvantages of BLDC Motors

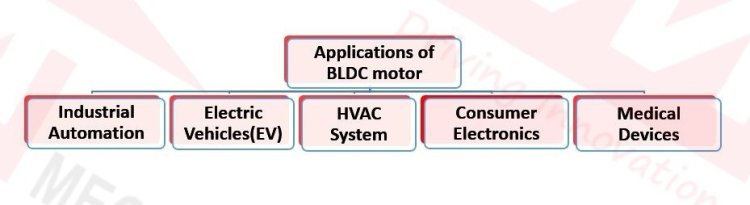

Applications of BLDC Motors

BLDC motors are the powerhouse of every application. They drive force in our daily applications whether it be a washing machine to clean clothes or a computer to drive data. In fact, in factories, this high-torque DC motor is used for manufacturing and assembling components. Its importance in the application is versatile. They are heroes in making our lives easier and more efficient.

BLDC Motor Applications include:

- Industrial Automation

BLDC motors are an integral part of Industrial automation applications by offering efficient, reliable, and precise motion control. From powering conveyor systems to driving pumps, compressors, and packaging machinery, BLDC motors are used in every operation requiring accurate speed regulation, and high torque output.

Furthermore, with their compact size, high power density, and advanced control capabilities, BLDC motors are used in AGVs, industrial fans, and various material-handling equipment to enhance productivity and optimize processes.

- Electric Bikes

BLDC motors are the most preferred choice for electric bikes due to their efficiency, power, and durability. BLDC motors offer high torque and power output which enable the electric bikes to climb hills and reach higher speed easily. They are compact and lightweight construction makes them ideal for integrating into bicycle frames.

They have the ability to regenerate energy during barking which is also known as regenerative braking improve efficiency and extend the battery range of electric bikes. Their precise controllability allows for smooth acceleration and quick braking which enhance the overall riding experience.

Outrunner BLDC motors are often used in electric bikes due to their high torque density and efficient cooling, making them suitable for demanding applications.

- HVAC System

BLDC motors are important components in HVAC systems by offering efficiency and precision in operation. These motors power the fans and blowers to ensure optimal airflow for heating, cooling, and ventilation through precise speed control.

Additionally, BLDC motors are used in controlling dampers, valves, and pumps to regulate the airflow, temperature distribution, and water circulation within HVAC Systems. BLDC motors are also us in air purification systems to purify indoor air quality by efficiently circulating and filtering the air.

Outrunner brushless DC motors are often used in these applications for their high torque output and compact design, enabling efficient performance in space-constrained HVAC setups.

- Consumer Electronics

BLDC motors are the essential components in the functioning of various consumer electronics devices by offering efficiency, reliability, and precise motion control in movement. From powering cooling fans in the computer to driving spindle motors in hard disk devices BLDC motors ensure reliable operation with minimal energy consumption.

BLDC motors are also found in various consumer applications such as vacuum cleaners, refrigerators, and washing machines, where their efficient performance contributes to energy savings and enhanced user experience.

- Medical Devices

BLDC motors are indispensable components in various medical devices by offering precision and efficiency in operation. The motors power various critical applications such as imaging systems like MRI machines and CT scanners, where they offer precise machinery movements and patient positioning.

BLDC motors are used in ventilators, infusion pumps, and respiratory devices, ensuring reliable airflow and accurate medication delivery for patient care. Furthermore, BLDC motors are used in diagnostic equipment, mobility aids, and rehabilitation devices, by supporting accurate sample processing, powered mobility, and rehabilitation exercises.

Why are BLDC Motors Important in today's world?

Today industries are under pressure to enhance productivity with energy consumption and cost saving. BLDC motors with their bushless design and energy-efficient quality are the perfect solution for today's industry needs.

The modern manufacturing industry relies on precise control of machinery for manufacturing processes. BLDC motors are known for their precise control over the speed and torque and become a pivotal solution in precision-demanding applications.

Today world is smoothly shifting towards automation, smart factories, and interconnected systems. Its compatibility with the electronics control system ensures a seamless automated manufacturing process.

Today various sector requires continuous operation with high reliability. BLDC motors are more reliable and sustainable solutions than traditional brushed motors. These motors have less wear-out time, a long life span, and low maintenance cost which ensure continuous operation without an uninterrupted production.

Industries and applications are switching towards smaller and more efficient solutions. They are integrating compact solutions in a wide range of applications. BLDC Motor's compact design allows it to fit into small spaces and makes it an ideal solution for industries where space is a concern.

Therefore, BLDC motors have great scope in the future as they emerged as an effective solution in today’s industries by addressing multiple challenges and fulfilling industrial needs by driving enhanced productivity, sustainability, and efficient production.